Analysis method for nucleation of metal hydride containing surface oxide layer

A surface oxidation and analysis method technology, applied in the field of nuclear technology application, can solve the problems of interference measurement results, damage, inability to meet the requirements of metal hydride reaction measurement, etc., and achieve the effect of simple sample preparation and good statistics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] The metal to be tested in this embodiment is a cerium metal sample, and the sample piece is polished on the same sandpaper for the same time, and stored at 200° C. in a 100KPa argon-oxygen mixture for about 10 hours to generate a certain thickness of oxide layer on the surface of the sample. The small-angle scattering test instrument is the Suanni neutron small-angle scattering spectrometer at the Mianyang Research Reactor in China.

[0044] The analytical method of the metal hydride nucleation that contains surface oxide layer in this embodiment, concrete steps are as follows:

[0045] a. Prepare a thin sheet-shaped cerium metal sample to be tested;

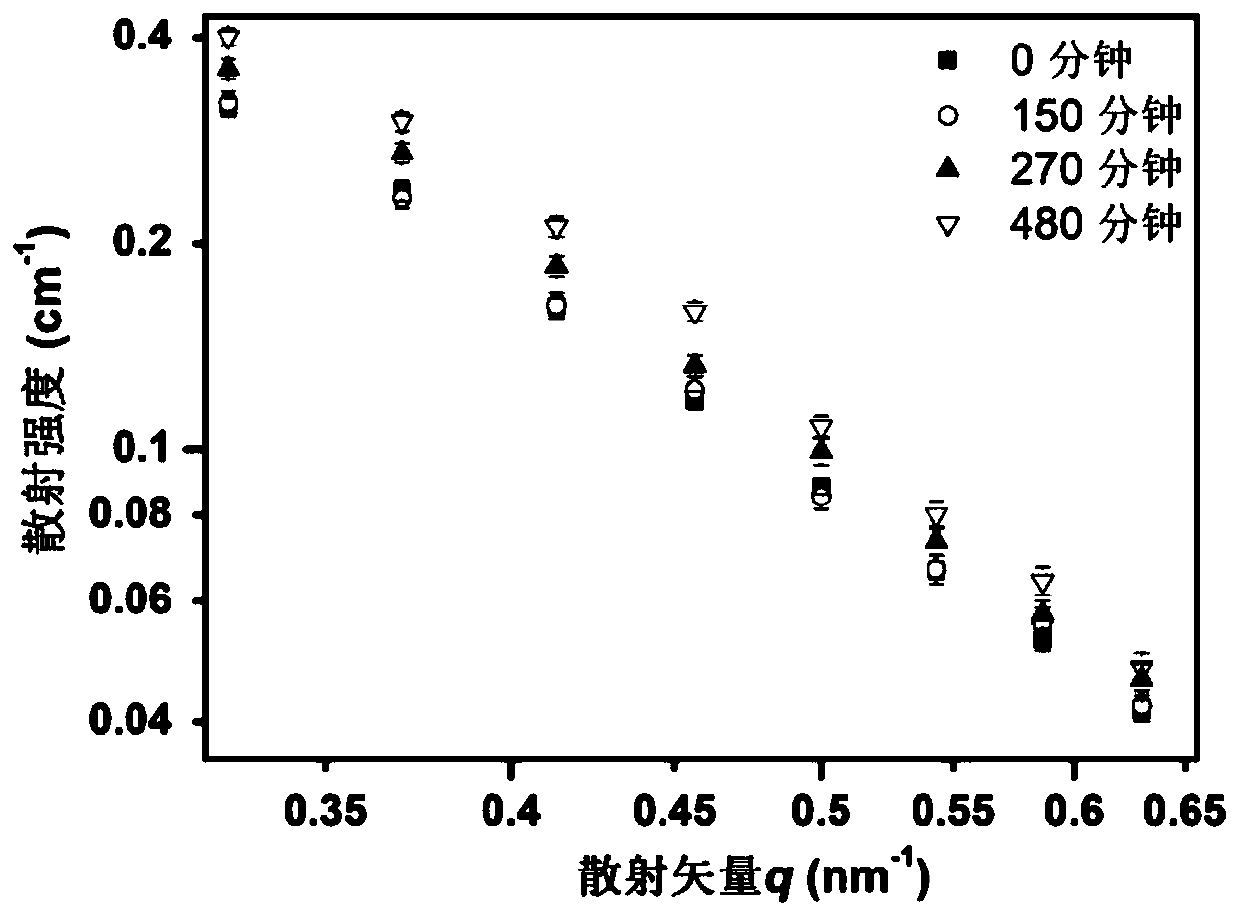

[0046] b. Place the cerium metal sample to be tested in the hydrogenation reaction chamber, continuously inject deuterium gas into the chamber, and carry out the small-angle neutron scattering test at the same time, and obtain the small-angle scattering of the metal sample to be tested at different time points during the ...

Embodiment 2

[0051] In this embodiment, the analysis method of metal hydride nucleation containing surface oxide layer, except for step (d), other operating steps are the same as in embodiment 1, wherein, step (d) is specifically:

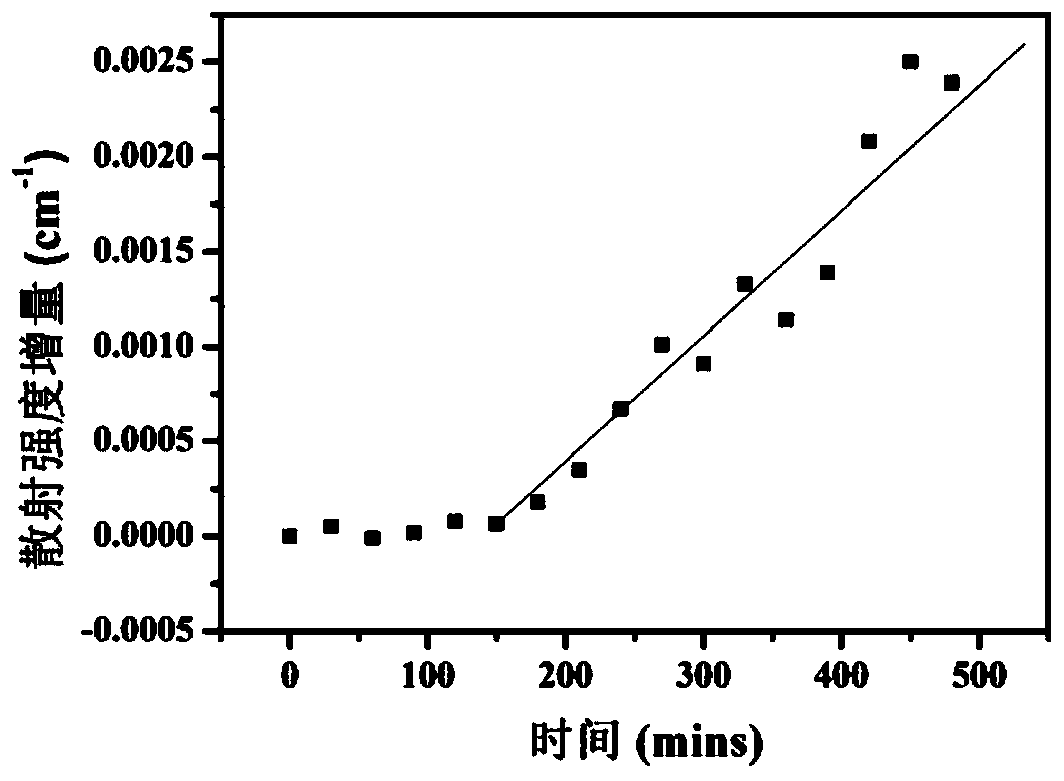

[0052] Choose fixed scattering vector 0.41nm -1 , read the scattering intensity of the scattering vector for all the absolute intensity scattering curves, analyze the change of the scattering intensity with time, and the time when the scattering intensity starts to increase is the critical point of hydride nucleation.

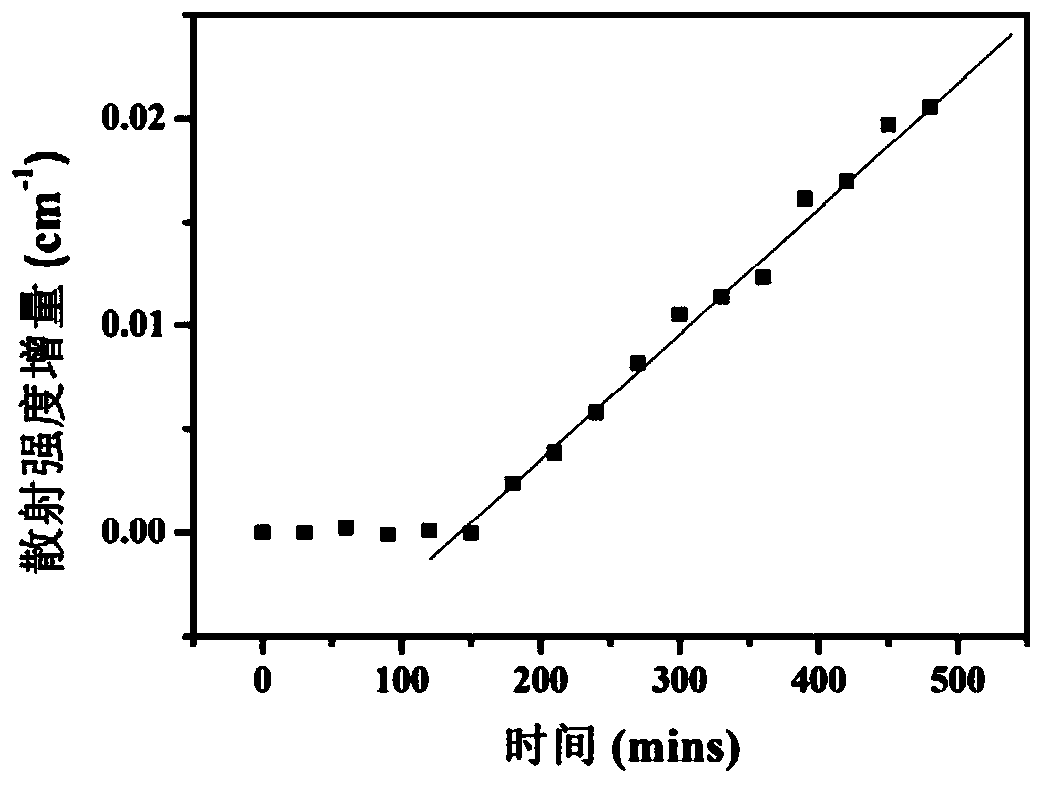

[0053] In this embodiment, the scattering intensity of the small-angle scattering curve of the sample at different time points of the hydrogenation reaction is obtained at a fixed scattering vector, and the initial scattering intensity is deducted to obtain the scattering intensity increment in the hydrogenation reaction. image 3 The relationship of the scattering intensity increment with time is given. It can be seen that the scattering inten...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com