Three-dimensional network type aqueous binder, preparation method thereof and electrode plate

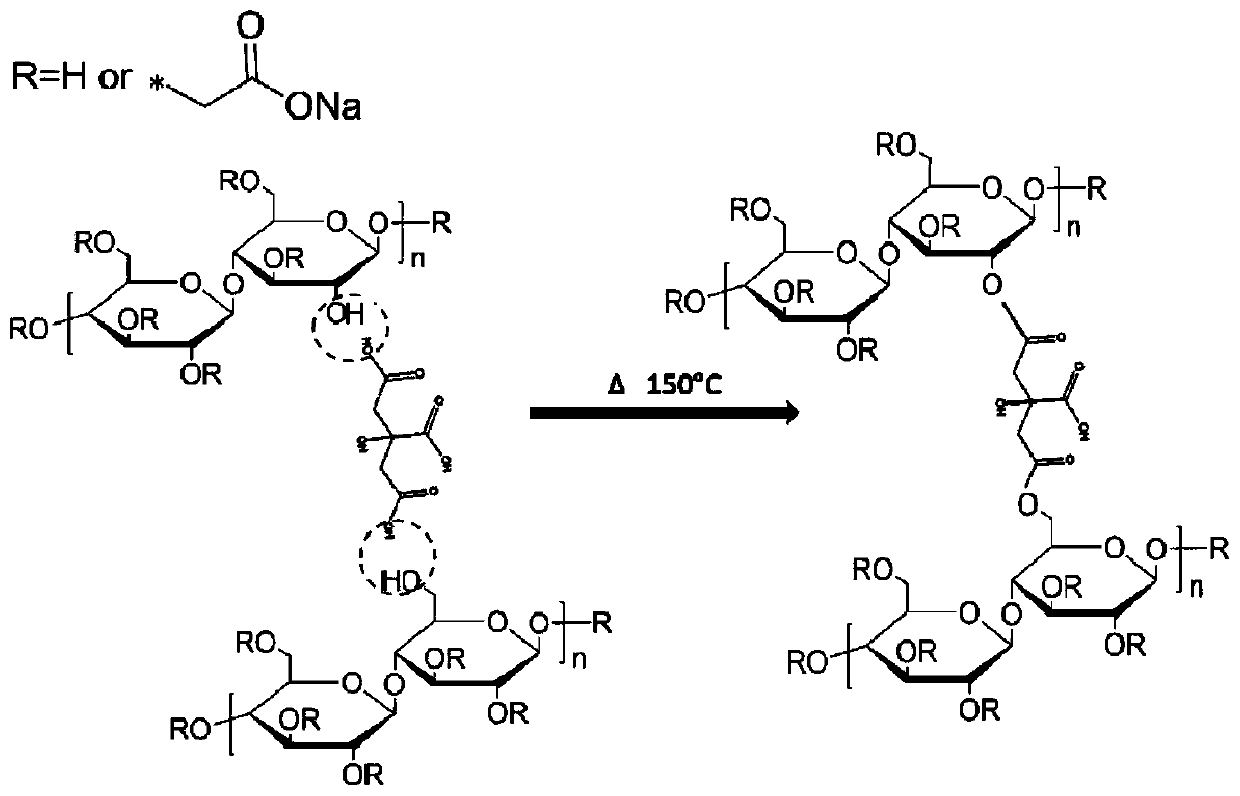

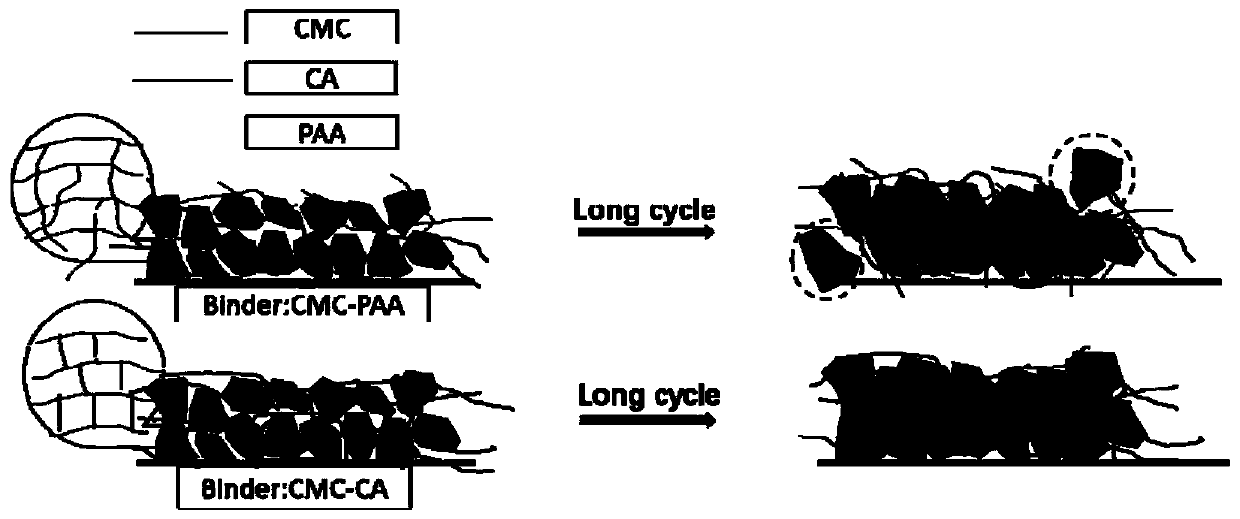

A three-dimensional network and binder technology is applied in the field of three-dimensional network water-based binders and preparation methods thereof and electrode sheets to achieve the effects of relieving failure, maintaining stable capacity and strong binding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] This example is used to illustrate a method for preparing a silicon carbon negative electrode sheet.

[0050] 1. Raw materials

[0051] Ingredients

[0052]

[0053]

[0054] 2. Preparation method

[0055] (1) Dry-mix conductive agent 1, conductive agent 2 and active material uniformly (revolution 25rpm) for about 0.5 hours, then add CMC and CA, keep the temperature in the stirring tank below 60°C and continue mixing (revolution 25rpm, Autorotation 1000rpm) for 30 minutes, add 50% water for pre-kneading (revolution 15rpm) for 30 minutes, continue mixing (revolution 15rpm) for 150 minutes, then add the same amount of water as before, vacuumize the tank and stir (revolution 30rpm, rotation 1500rpm) for 30 minutes, add NMP, vacuumize and continue to mix and stir (revolution 30rpm, autorotation 2800rpm) for 2 hours, finally add SBR, vacuum mix and stir at low speed (revolution 25rpm, autorotation 1000rpm), a uniform and stable black water-based slurry should be obta...

Embodiment 2

[0063] Add 10 mass parts of Super P conductive agent and 9 mass parts of CMC binder and 1 mass part of citric acid auxiliary agent to 80 mass parts of active materials (using commercially available silicon carbon materials), mix and grind until The slurry is evenly viscous. Use a small medicine spoon to apply it on the cleaned copper foil. Shake it slightly to make the thickness of the slurry coating uniform. Then lay it flat on the table to dry in the shade. Put the copper foil up and down in a vacuum oven at 150°C, dry it for 2 hours and weigh it. The weighed pole pieces need to be placed in a vacuum oven again at 80°C, dried for 12 hours and stored in a glove box for later use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com