A Control Method of Two-Phase Parallel Synchronous Rectification Boost Converter Based on Forward Coupled Inductor

A technology of forward coupling and synchronous rectification, which is applied in the direction of converting DC power input to DC power output, adjusting electrical variables, and controlling/regulating systems. It can solve problems such as increased inductor current ripple, increased loss, and impact on efficiency. The effect of suppressing the inductor current ripple, reducing the loss of each component, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Embodiments of the present invention patents are described in detail below, examples of which are shown in the drawings, wherein the same or similar reference numerals represent the same or similar elements or elements having the same or similar functions throughout. The embodiments described below by referring to the drawings are exemplary, and are only used to explain the patent of the present invention, and cannot be construed as limiting the patent of the present invention. All modifications made according to the spirit of the main technical solutions of the present invention shall fall within the protection scope of the present invention.

[0030] Below in conjunction with accompanying drawing, the technical scheme of the patent of the present invention is described in further detail:

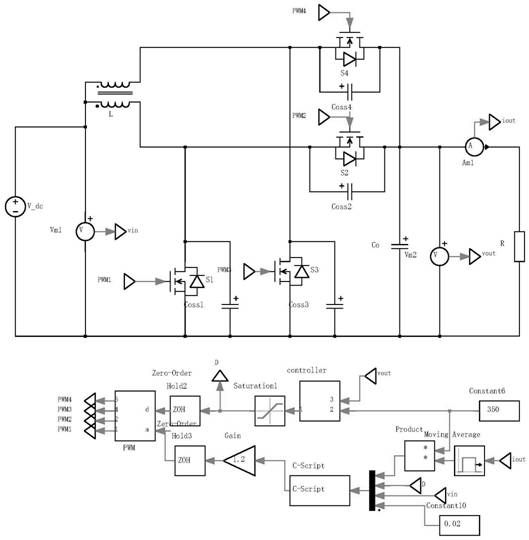

[0031] A two-phase parallel synchronous rectification Boost converter based on forward coupled inductors, comprising first to fourth power MOSFETs, coupled inductors, capacitors, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com