Novel hemostatic clip

A technology of hemostatic clips and clips, applied in the field of hemostatic clips, which can solve the problems of tissue tearing, expansion of release aperture, clip falling off, etc., and achieve the effect of avoiding tissue tearing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

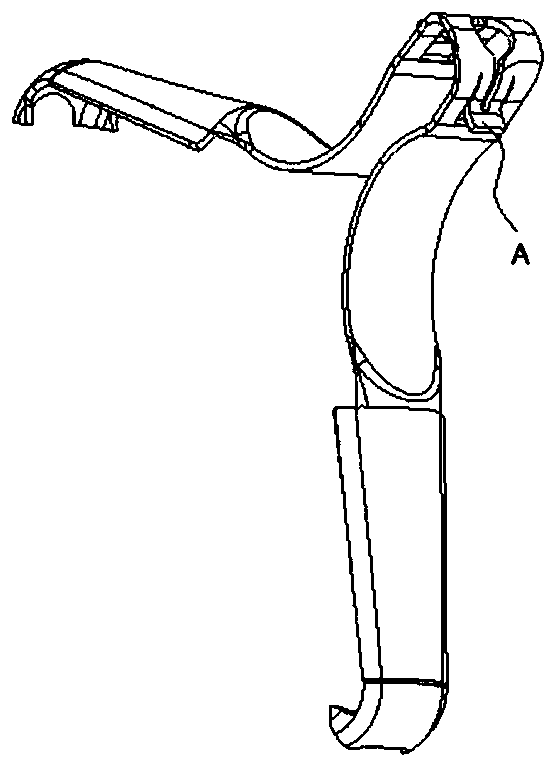

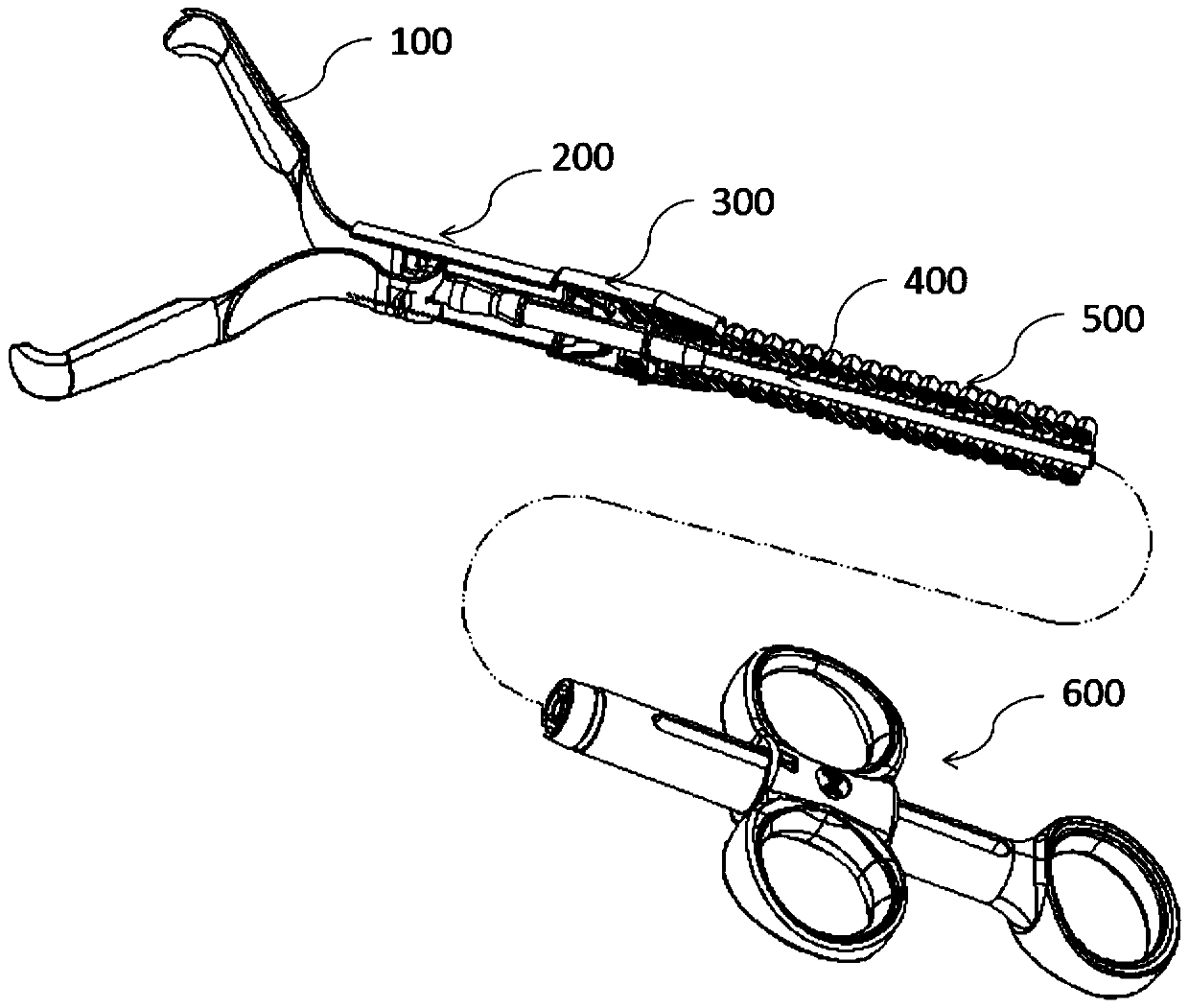

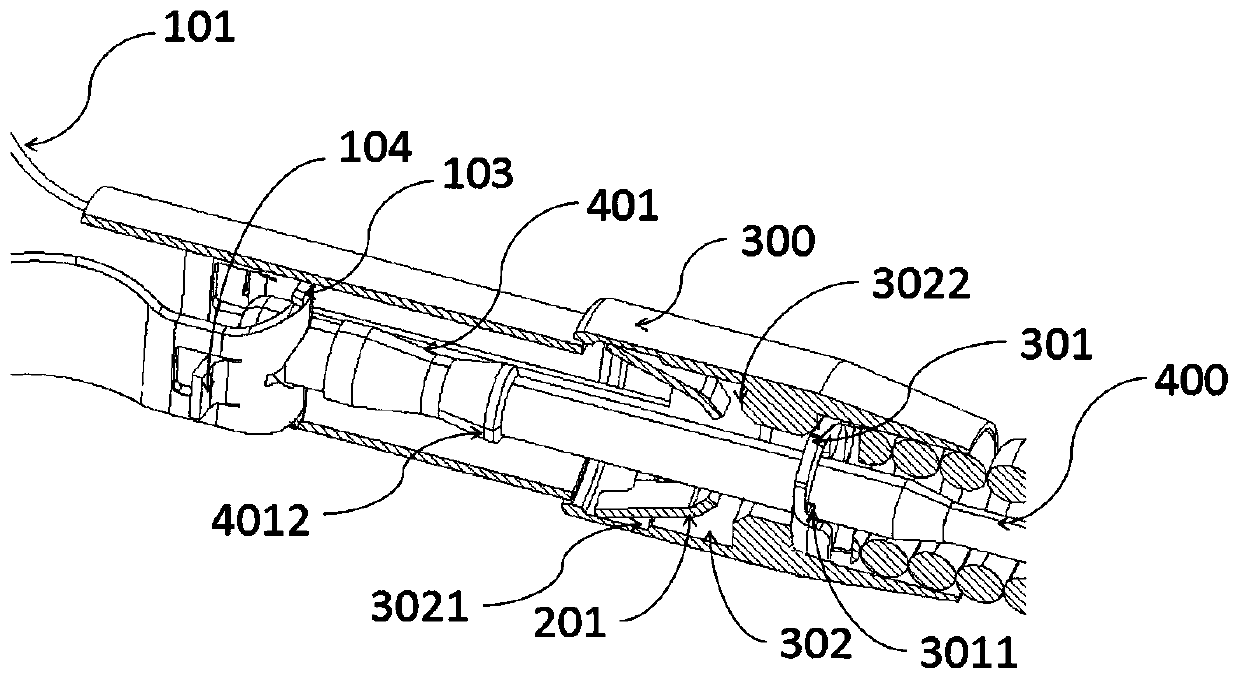

[0060] Such as Figure 1-5 As shown, in this embodiment, the hemostatic clip has a handle 600 on the proximal side, a clip assembly on the distal side, a sheath 500 between the handle 600 and the clip assembly 100, and a control wire 400 in the sheath 500, The distal end of the sheath tube 500 has a fixing seat 300 , and the distal end of the control wire 400 has a release portion 401 . Wherein, the clip assembly includes: a clip body 100, which has two clip arms 101, and a transition connection portion 102 connecting the two clip arms 101 proximally; channel, and the proximal side of the clip base is releasably connected with the fixing base. The proximal side of the clamp seat 200 has a retainer 201, and the fixed seat 300 has an open release chamber 302 towards the distal side. The distal tail of the retainer 201 is in a natural state and the locking groove 3021 on the distal side wall of the release chamber 302 Releasable snap connection, when the clip body 100 is in the...

Embodiment 2

[0077] Such as Figure 11a , Figure 11b As shown, the structure of the safety mechanism 301 in Embodiment 1 is transformed. In this Embodiment 2, the outer periphery of the distal end surface of the safety mechanism 301 forms an equilateral triangle. Do arc chamfering. There is a through hole 3013 in the center of the safety mechanism, and each radially protruding protrusion 3011 on the inner wall of the through hole 3013 has a bend that deflects toward the proximal end. When sliding to the distal side, it can pass through the safety mechanism 301 more smoothly, and when the part of the diameter reducing part 4012 with the largest radial length exceeds the proximal surface of the protruding part 3011, it can provide a higher abutment force and prevent it to the greatest extent. The line of control is again moved distally to achieve a better insurance effect. In this embodiment, the proximal surface of the safety mechanism 301 has the sheath tube abutting portion 3012 arran...

Embodiment 3

[0079] Such as Figure 12 As shown, the structure of the insurance mechanism 301 in Embodiment 1 is transformed. In Embodiment 3, the distal end surface of the safety mechanism has a circular structure, and six protrusions 3011 protruding radially inward are arranged at equal intervals on the inner peripheral wall of the safety mechanism 301, the protrusions extend radially, and the six protrusions It provides a more reliable limit capability and better ensures the one-way movement of the control line. At the same time, the proximal end surface of the safety mechanism 301 has a circular end surface adapted to the distal surface of the sheath, so that the proximal surface and the distal surface of the safety mechanism 301 are fully in contact with the sheath tube and the fixing seat respectively, and the lifting device is stable and reliable The connectivity performance, thus ensuring the effectiveness of the insurance agency.

[0080] Of course, as the deformation method of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com