Salt lake brine filtering method

A technology of salt lake brine and filtration method, applied in the directions of filtration and separation, separation method, filtration loop, etc., can solve the problems of reduced filtration performance of filtration device, unable to guarantee the production process requirements of magnesium chloride brine, etc., and achieves the goal of reducing brine turbidity and improving quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0086] Hereinafter, the present invention will be described in detail with reference to Examples to specifically describe the present invention. However, the embodiments of the present invention may be modified into various other forms and the scope of the present invention should not be construed as being limited to the embodiments described below. The embodiments of the present invention are provided so as to more fully describe the present invention to those skilled in the art.

[0087] Unless otherwise specified, the equipment or raw materials in the following examples can be obtained from commercial channels such as general markets or can be easily obtained by self-made.

preparation example 1

[0089] During the processing of salt lake brine minerals, the salt field brine (from Jinel Salt Lake, Golmud City, Qinghai Province) is exposed to the sun for 30 days, and stored in an open brine pool (100,000 cubic meters) to obtain brine before filtration. The temperature is 20°C.

Embodiment 1

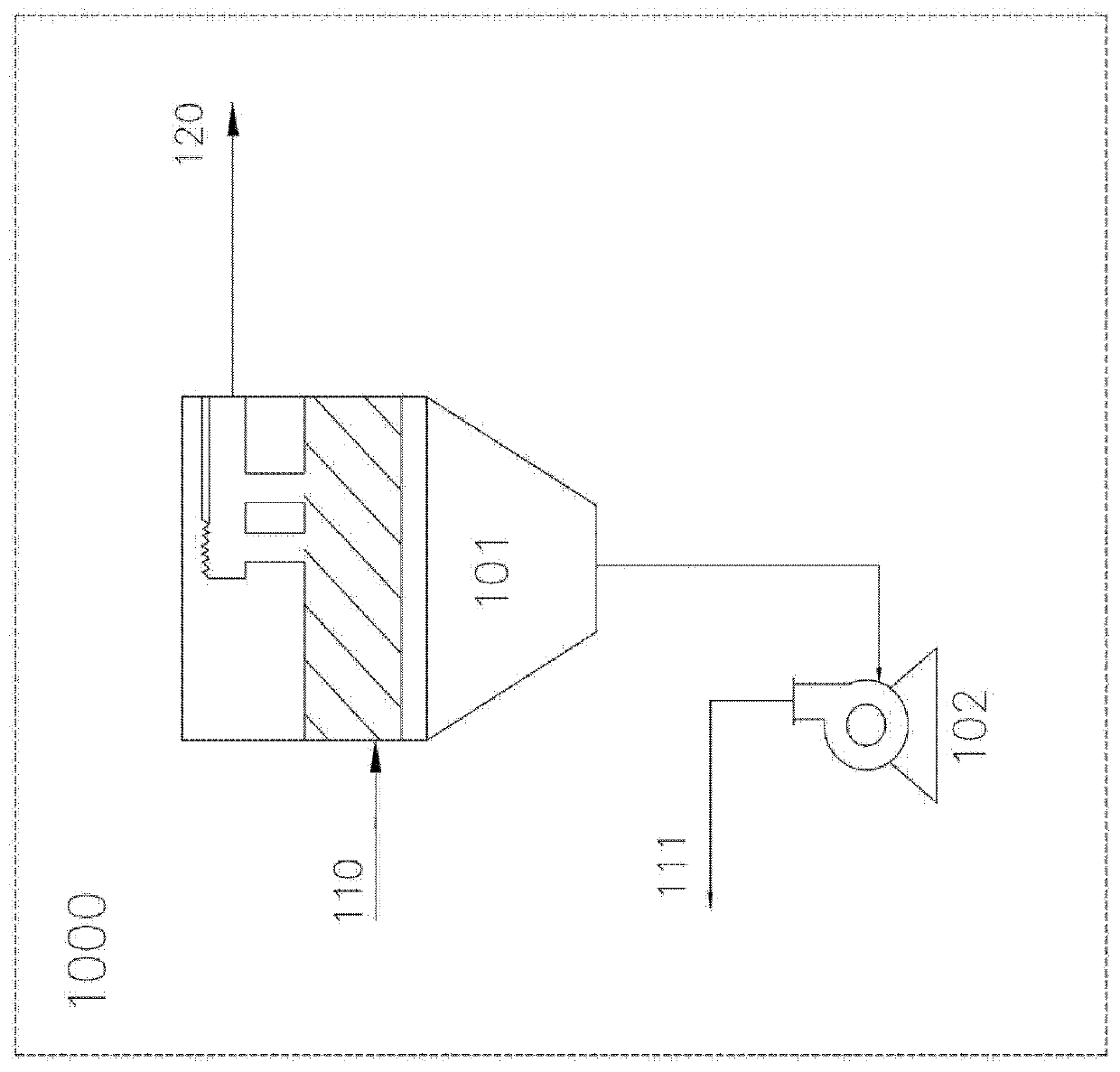

[0091] first level filter

[0092] To the bittern (30m) before filtering of Preparation Example 1 3 / h) Carry out the treatment of the first-stage brine filtration process, wherein the brine before the filtration enters the first-stage brine filtration system, which includes an inclined plate inclined tube settling tank (from Jiangsu Zhongye Smelting Chemical Co., Ltd.) as the first brine filtration mechanism Equipment Co., Ltd., material: FRP). Specifically, the brine enters from the lower feed inlet of the inclined tube settling tank, and settles through the inclined plate in the tank step by step (the inclination angle of the inclined plate is 60°). The filtered brine flows out from the overflow port to obtain the first stage filtered brine.

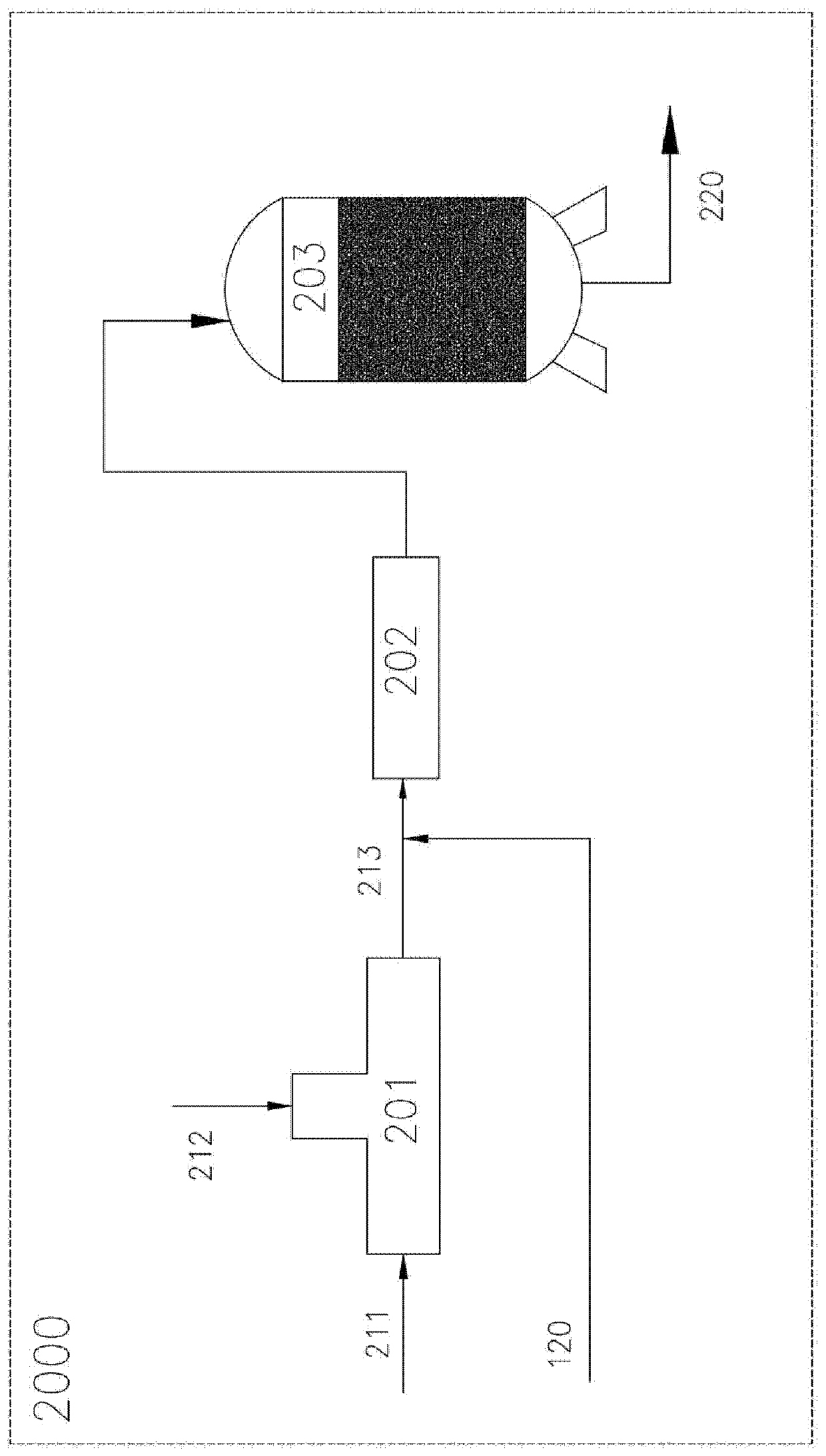

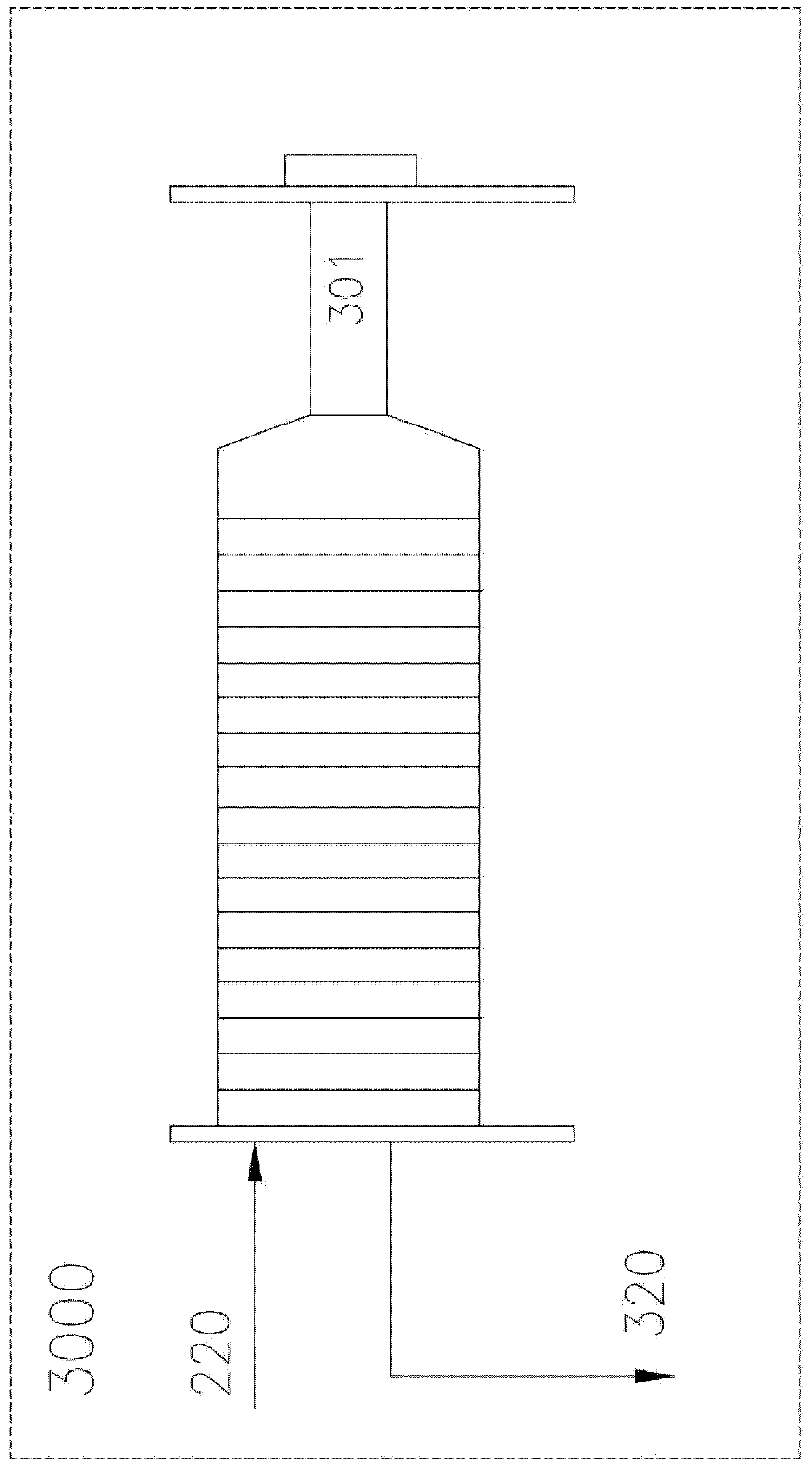

[0093] second stage filter

[0094] The brine (30m 3 / h) Carry out the treatment of the second-stage brine filtration process, wherein the brine after the first-stage filtration enters the second-stage brine filtration system, whi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com