Desulfurization and denitrification integrated device

A technology of desulfurization and denitrification and desulfurization devices, which is applied in the field of desulfurization and denitrification, can solve the problems of high manufacturing cost and large equipment footprint, and achieve the effects of saving operating costs, small flue gas flow resistance, and heat loss control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

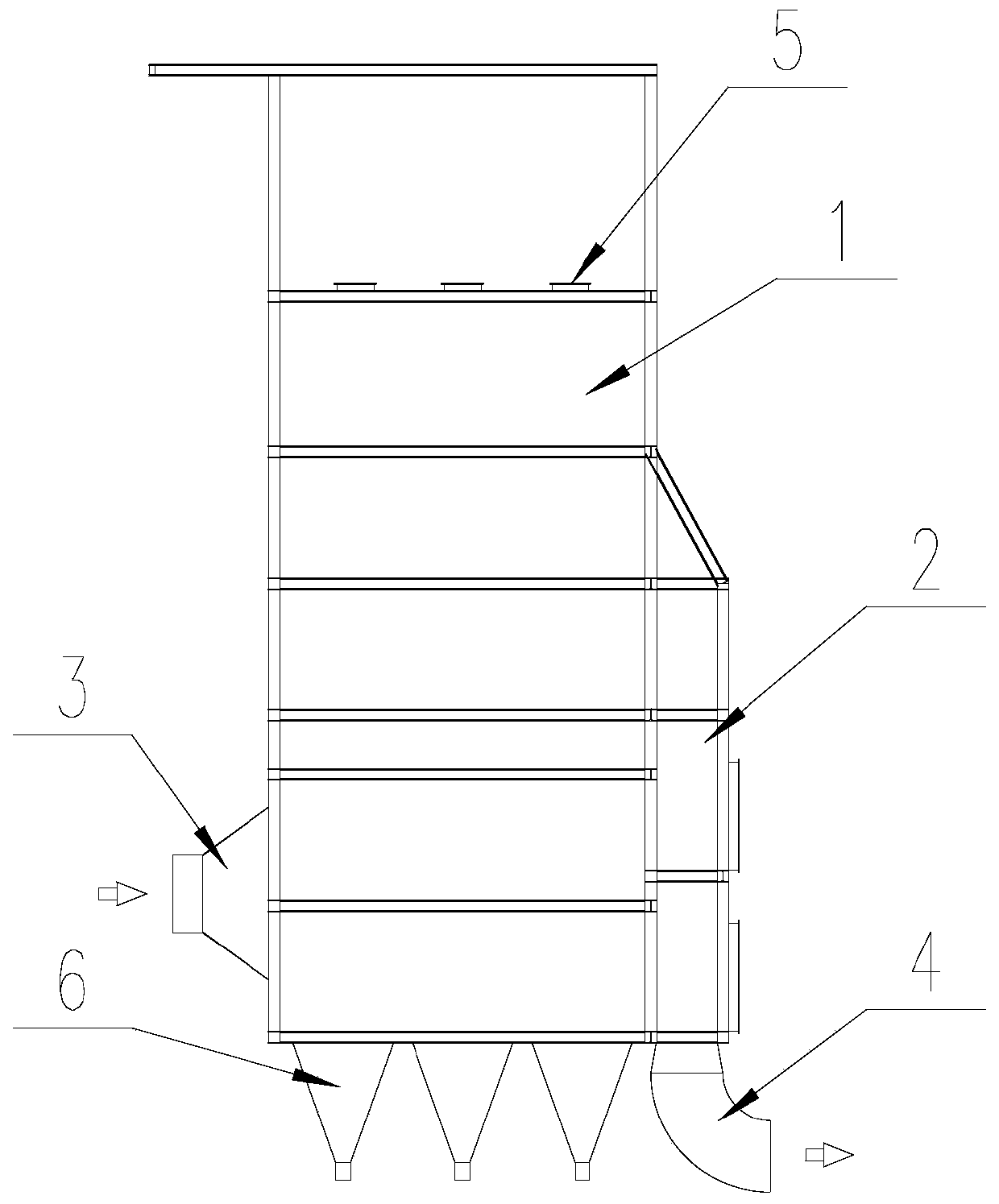

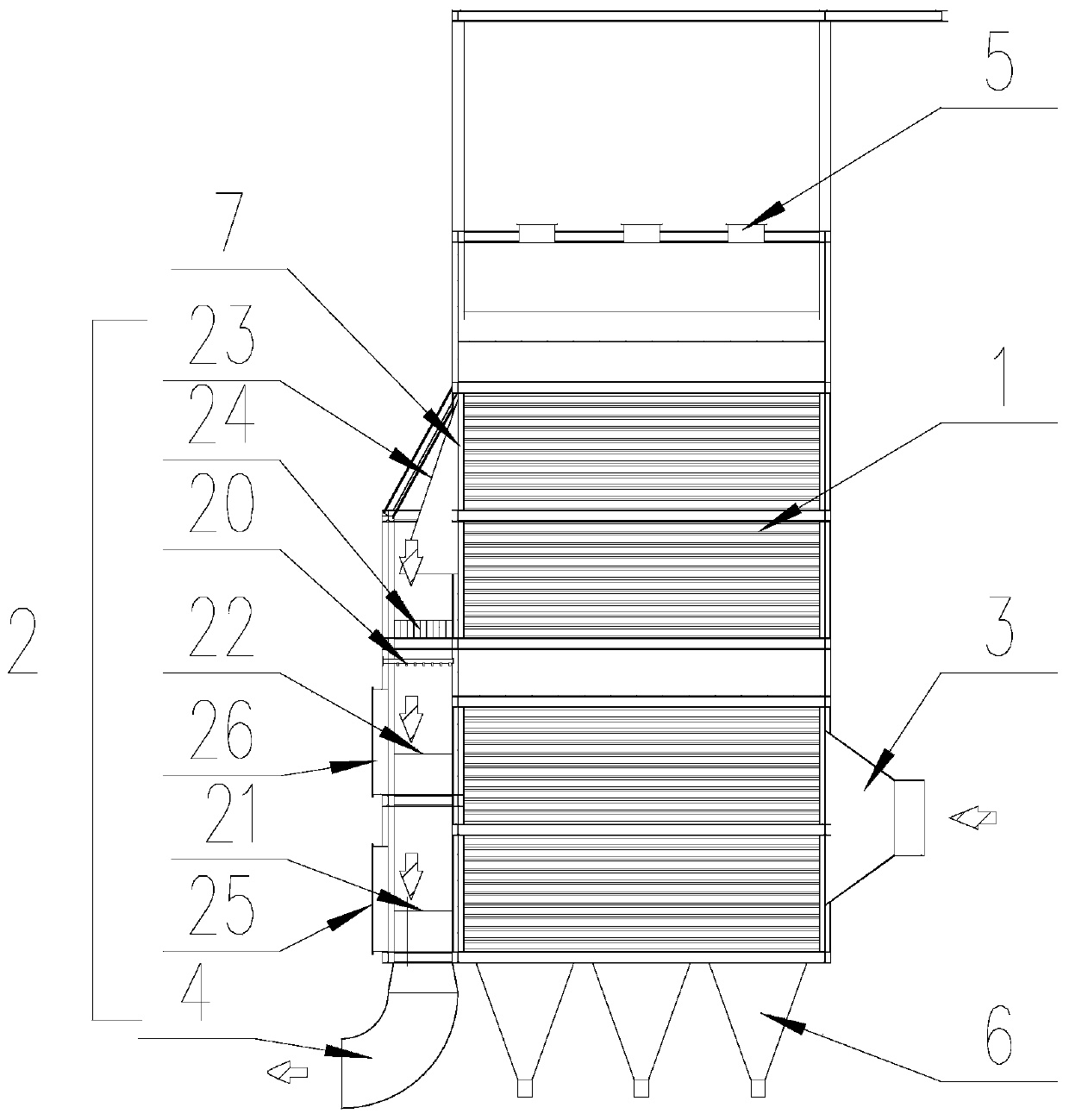

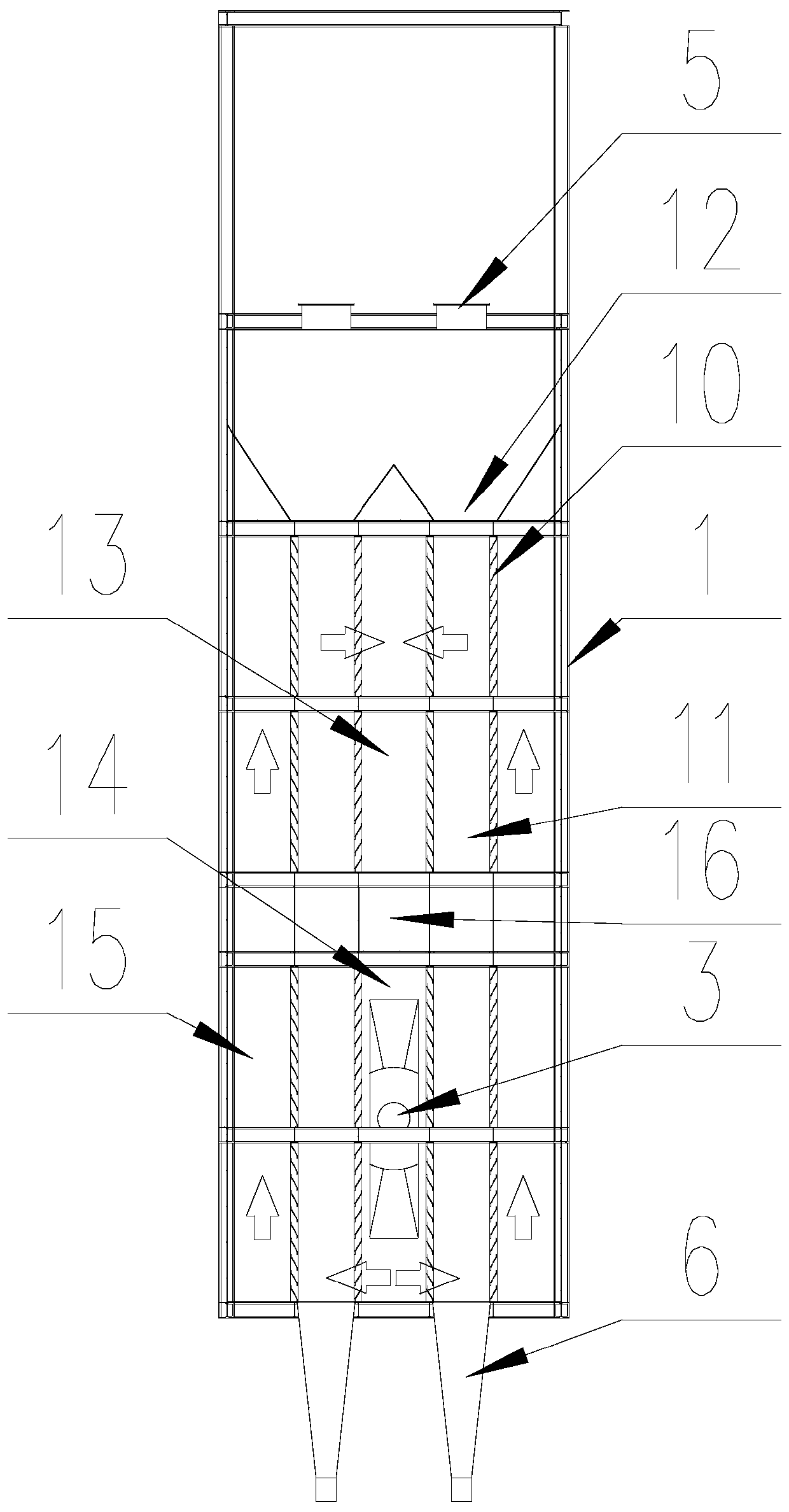

[0038] Such as Figure 1 to Figure 3 As shown, a desulfurization and denitrification integrated device includes a desulfurization device 1 and a denitrification system 2, the denitrification system 2 is arranged adjacent to the desulfurization device 1, and a flue gas inlet 3 is provided under the side of the desulfurization device 1, so A flue gas outlet 4 is provided under the side of the denitrification system 2, and the desulfurization device 1 and the denitrification system 2 are connected through a desulfurization flue gas outlet 7. The desulfurization flue gas outlet 7 is located above the side of the desulfurization device 1 and is located at The opposite side of the flue gas inlet 3.

[0039] The desulfurization device 1 includes a desulfurization agent feeding port 5 and a desulfurization grid 10 , the desulfurization grids 10 are arranged at intervals to form a desulfurizing agent filling chamber 11 , and the desulfurizing agent feeding port 5 communicates with the de...

Embodiment 2

[0047] The difference between this embodiment and Embodiment 1 is that a denitrification catalyst standby layer 22 is also provided between the ammonia injection grid 20 and the catalyst placement layer, and the denitration catalyst standby layer 22 is provided with a second transfer gate 26. When the amount of catalyst is small and the catalytic effect becomes poor, a spare catalyst can be added to the denitration catalyst spare layer 22 through the second transfer gate 26 to promote the normal progress of the denitration reaction.

Embodiment 3

[0049] The difference between this embodiment and Embodiment 2 is that the denitrification system 2 is also provided with a flow guide device 23 and a rectification grid 24, the flow guide device 23 is arranged at the desulfurization flue gas outlet 7, and the rectification grid The grid 24 is located below the deflector 23 and above the ammonia injection grid 20 .

[0050] The specific operation process is:

[0051] The desulfurizer is transported to the top of the desulfurization tower with a ton bag, and the ton bag is sent to the top of the desulfurization device 1 through an electric hoist, and then the ton bag is manually opened, so that the desulfurizer automatically enters through the desulfurizer feeding port 5 and through the material guide port 12 The desulfurizing agent filling cavity 11 can also be automatically loaded by bucket lifting and conveying devices. During the specific treatment, after the flue gas from the coke oven enters the desulfurization device 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com