Collaborative optimization energy management method of parallel hybrid electric vehicle

A hybrid electric vehicle and collaborative optimization technology, applied in hybrid electric vehicles, motor vehicles, data processing and management, etc., can solve a large number of floating-point calculations, poor real-time performance and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

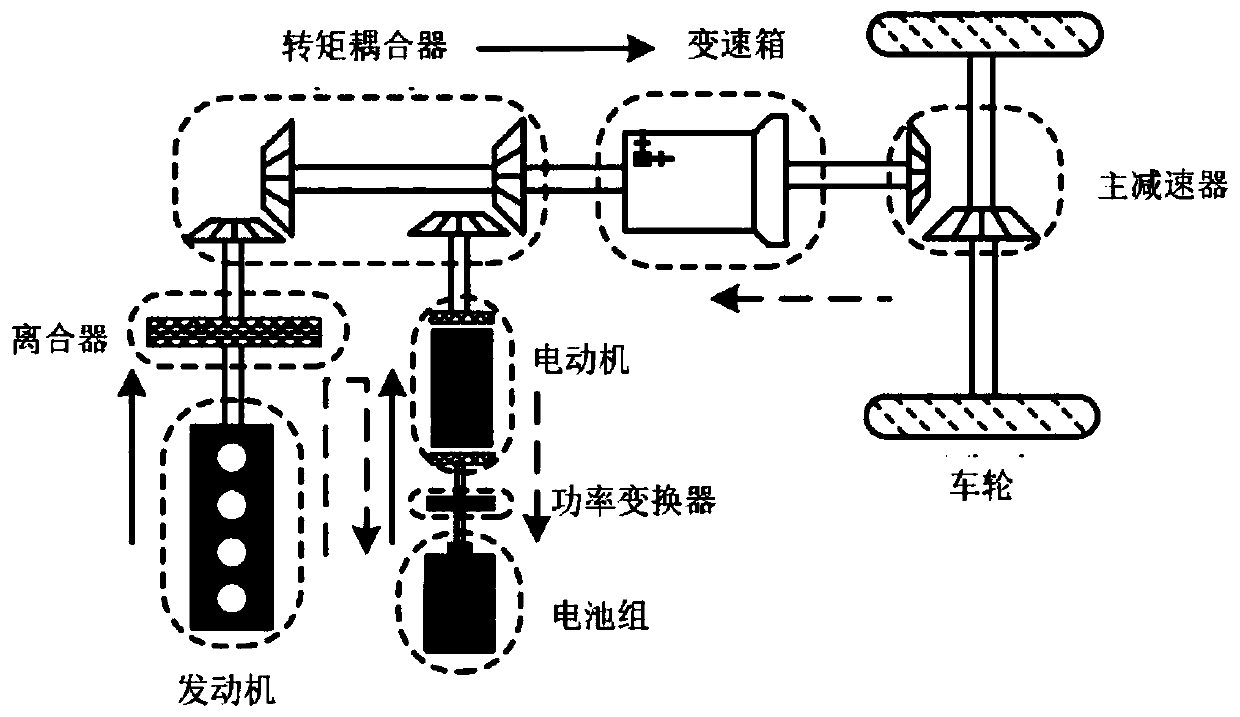

[0094] 1) Parallel hybrid vehicle model parameters The vehicle mass is 1350 kg, the air resistance coefficient CD=0.335, the windward area FA=2.0 square meters, the wheel rolling radius Rr=0.282m, the rolling damping coefficient f=0.009, and the average transmission efficiency ηt=0.85 .

[0095] 2) Parallel hybrid electric vehicle engine model: parameters: model is FC_SI41_emis, maximum power / speed=41kw / 5700r.min-1. Maximum torque / speed = 81N.m / 3500r.min-1.

[0096] 3) Parallel hybrid electric vehicle motor model parameters: model is MC_AC75, rated power PN=75kw, rated speed nN=2000r / min, maximum speed nmax=10000r / min, average efficiency 0.92.

[0097] 4) Parallel hybrid electric vehicle battery model Ni-MH battery parameters: the model is ESS_NIMH28_OVONIC, the standard discharge capacity is 28Ah, and the number of battery blocks is 50.

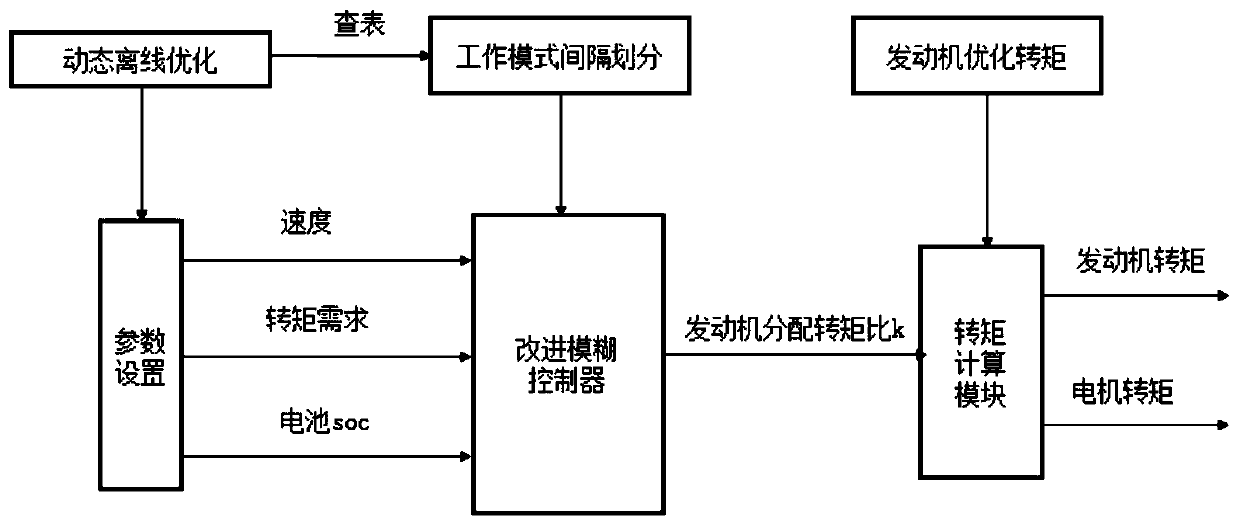

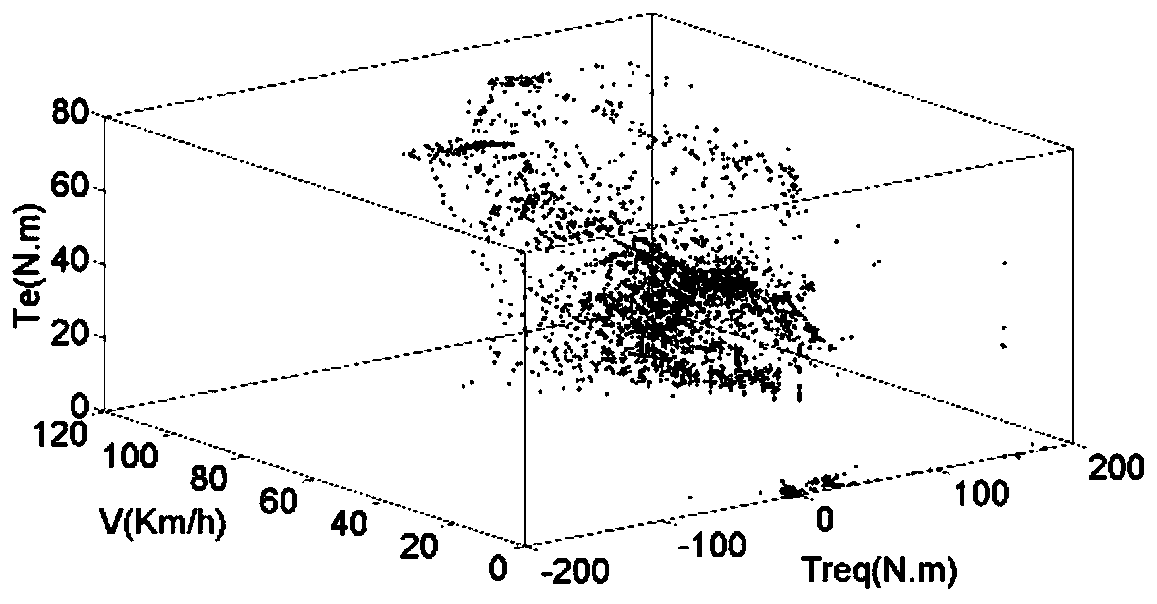

[0098] Furthermore, after the hybrid vehicle model is established, the collaborative optimization energy management system is established...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com