Preparation method for antibacterial fabric, antibacterial fabric and antibacterial product

A technology of antibacterial fabrics and antibacterial products, applied in the field of antibacterial, can solve the problems of reducing antibacterial activity, complex process, unfavorable environmental protection, etc., to achieve the effect of ensuring antibacterial activity, overcoming high cost, and cost environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

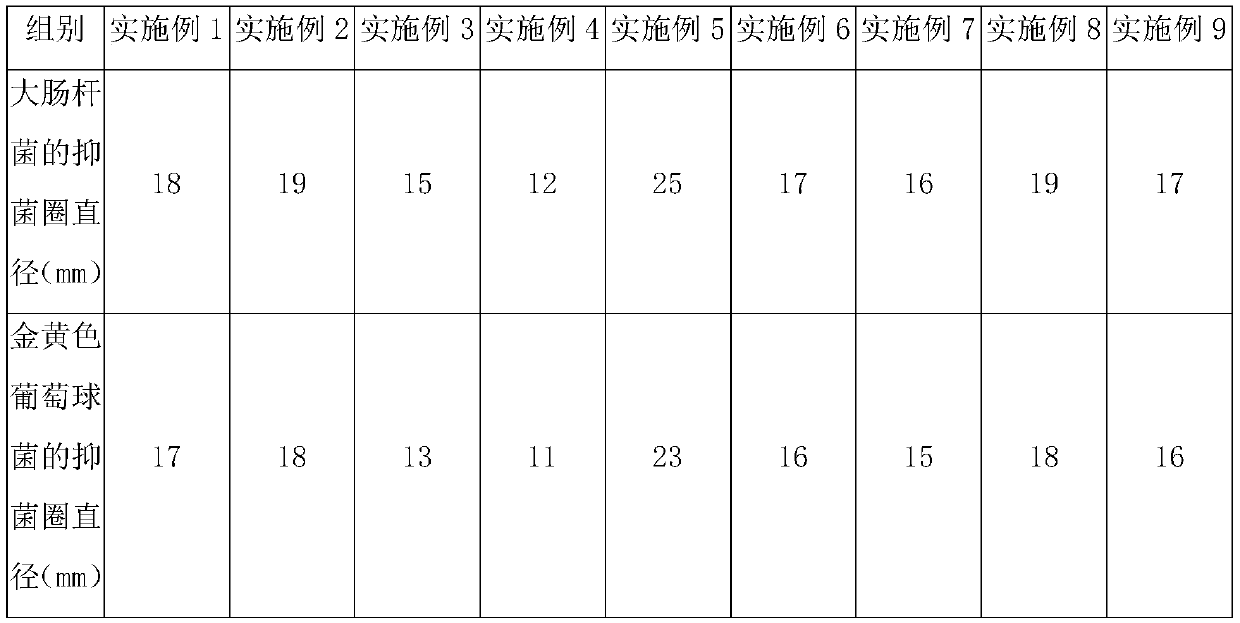

Examples

Embodiment 1

[0030] A kind of preparation method of antibacterial fabric, it comprises following preparation steps:

[0031] Step 1, adopt plasma treatment machine to carry out plasma treatment to fabric, the effective treatment width of described plasma treatment machine is 0.2m, the power during plasma treatment is 500W, and described plasma treatment time is 2.4s;

[0032] Step 2, adopting the micro-gravure printing process to coat the nano-silver antibacterial dispersion on the surface of the fabric;

[0033] Step 3, using an oven to dry the surface of the fabric, the length of the oven is 10m, the temperature during the drying treatment is 90°C, and the drying time is 2min;

[0034] Step 4: Using an infrared light box to treat the fabric with infrared light, the length of the infrared light box is 10 m, the infrared light wavelength during the infrared light treatment is 2 μm, and the infrared light treatment time is 2 minutes.

[0035] Wherein, the nano-silver antibacterial dispersi...

Embodiment 2

[0040] A preparation method of antibacterial fabric, wherein, the difference between the preparation method of embodiment 2 and embodiment 1 is that the power during plasma treatment in embodiment 2 is 1800W, and other preparation steps of embodiment 2 are the same as embodiment 1.

Embodiment 3

[0042] A preparation method of antibacterial fabric, wherein, the difference between the preparation method of embodiment 3 and embodiment 1 is that the power during plasma treatment in embodiment 3 is 100W, and other preparation steps of embodiment 3 are the same as embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com