A high-efficiency normal temperature drying equipment

A drying equipment, normal temperature technology, applied in drying, dryers, lighting and heating equipment, etc., can solve the problems of prolonged drying time, insufficient drying, large volume, etc., to improve cleanliness and flatness , the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

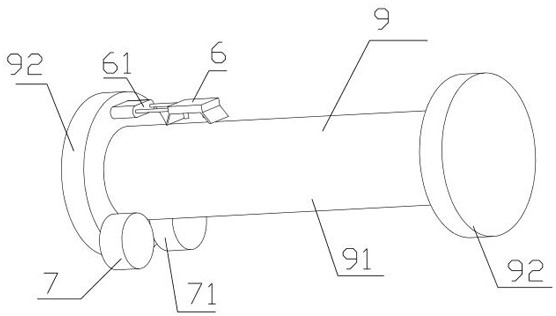

[0034] Embodiment one, such as figure 1 As shown, a high-efficiency room temperature drying equipment includes a roller 9, and the roller 9 includes side cylinders 92 on both sides and a main body 91 in the center. The side cylinder 92 is disc-shaped and does not rotate, and the main body 91 is column-shaped and is the main rotating part. The rotational force of the main body 91 comes from the driving device 7, and the driving device 7 is equipped with two rolling wheels 71, which conflict with the outer surface of the main body 91 and drive the main body 91 to rotate.

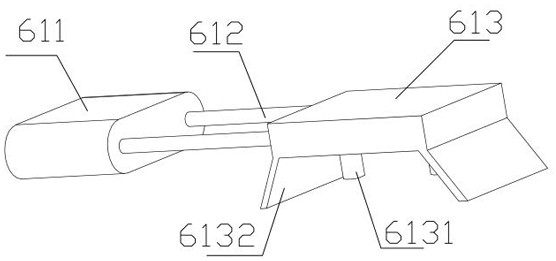

[0035] The heat of the main body 91 comes from the heating device 6 , in this case, the heating device 6 includes two parts, namely the main heating device 62 in the inner cavity of the main body 91 and the auxiliary heating device 61 around the main body 91 .

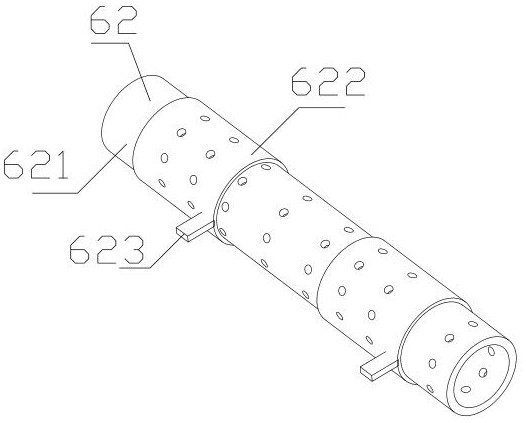

[0036] like figure 2 As shown, the main heating device 62 comprises a plurality of steam pipes 621 extending inside the drum 9 . The surface of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com