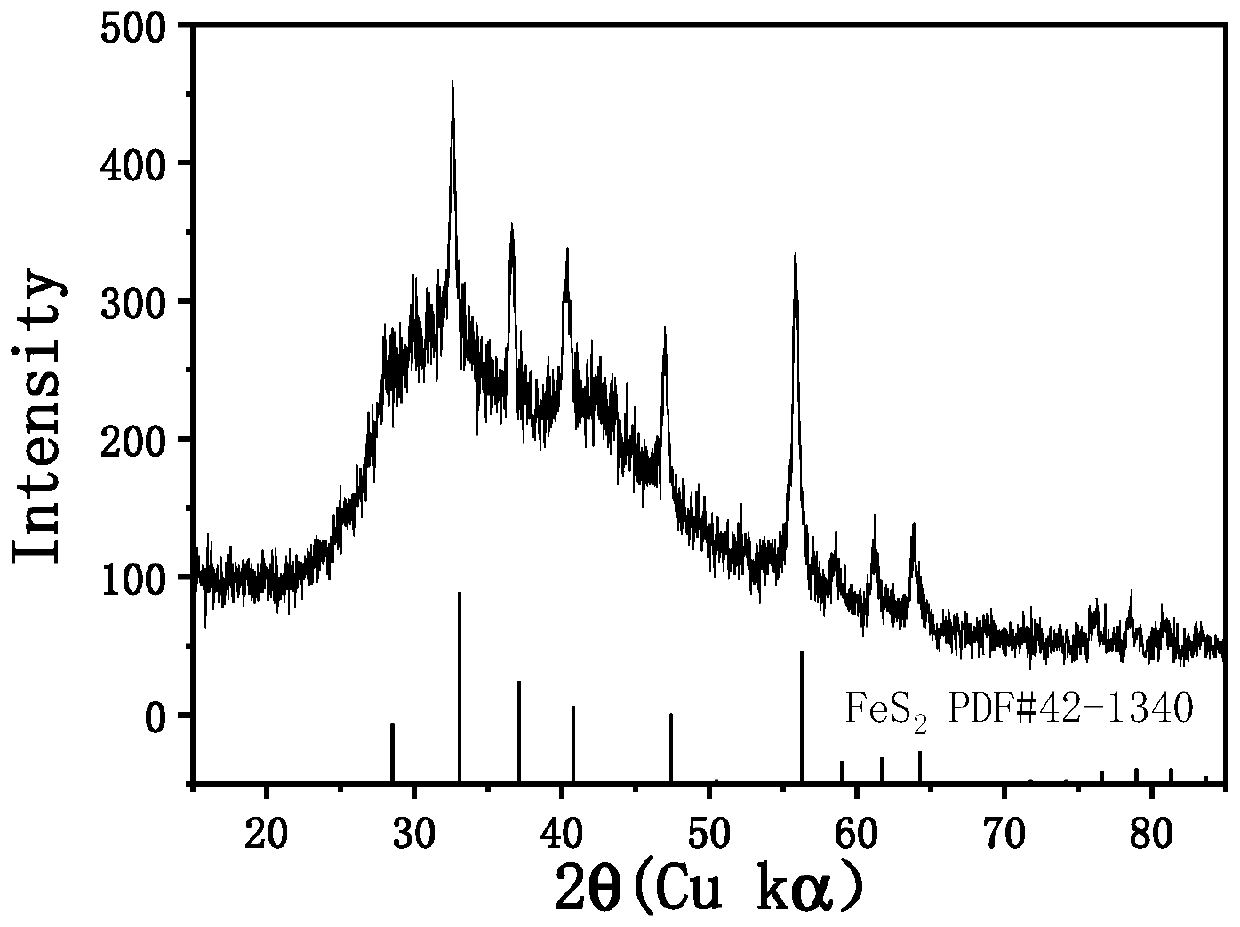

FeS<2-x>Sex solid solution cathode material and preparation method thereof

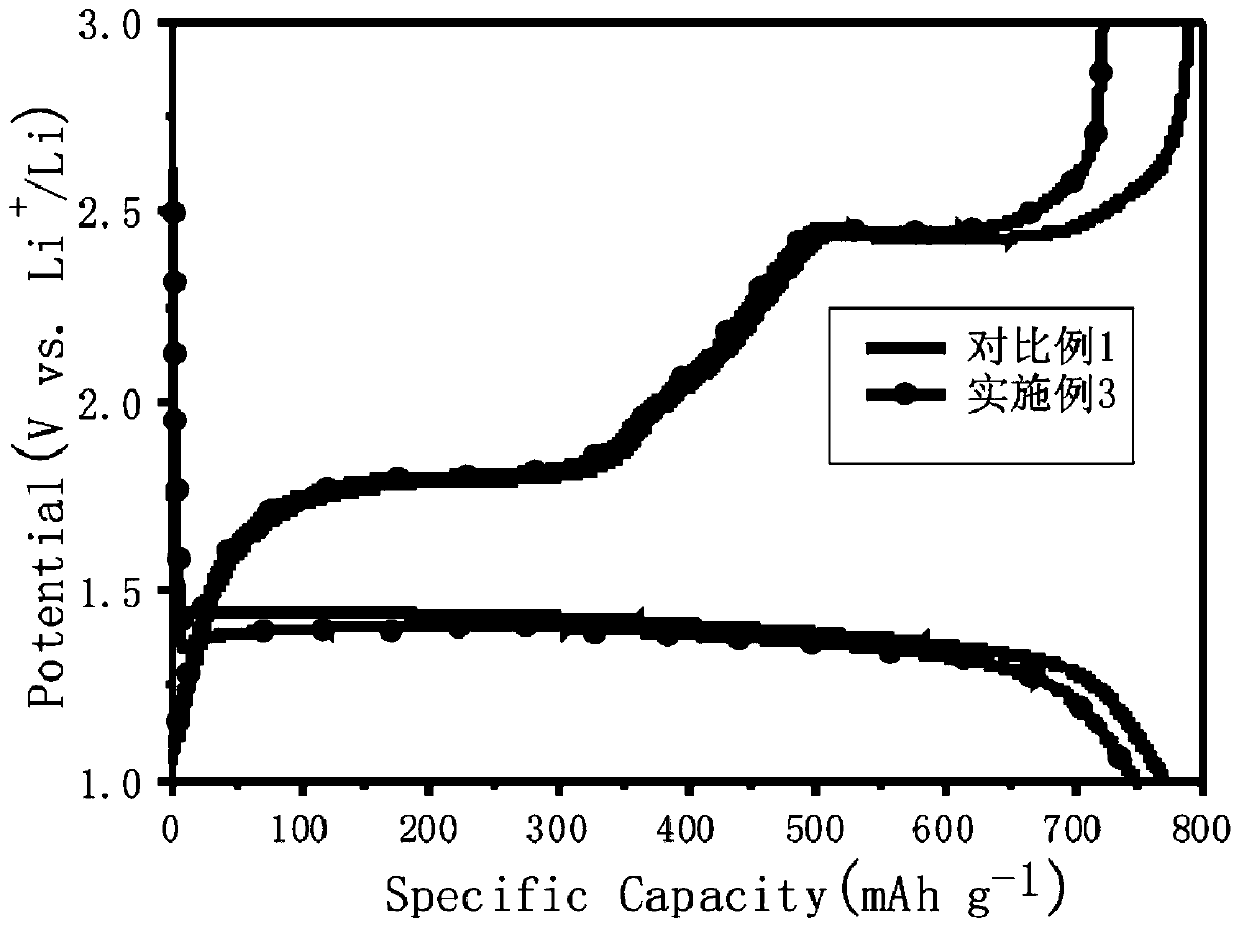

A cathode material and solid solution technology, which is applied in the field of FeS2-xSex solid solution cathode material and its preparation, can solve the problems of poor cycle stability of cathode materials, and achieve the effects of improving cycle stability, good buffer capacity and improving utilization rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] a FeS 2-x Se x Solid solution positive electrode material, its preparation method comprises the following steps:

[0033] (1) Add 1mmol iron oxalate and 0.3g PAN to 10ml DMF in turn, and stir at 800r / min at 25°C for 12h to obtain a uniformly dispersed spinning solution;

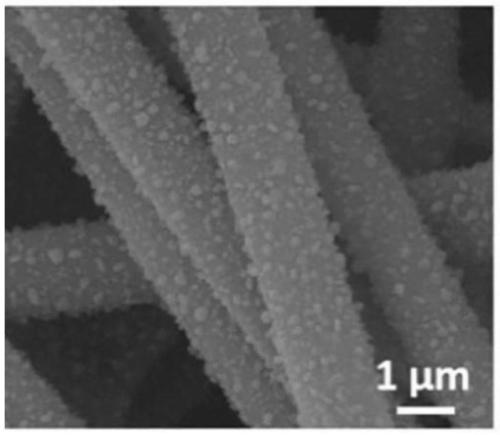

[0034] (2) By electrospinning, the spinning solution obtained in step (1) is spun into nanofibers distributed with iron precursors, and then heated to 1000°C at a heating rate of 10°C / min for 3 hours, and samples are collected after cooling;

[0035] (3) 2mmol S powder and 1mmol Se ball milled for 12h to obtain uniform mixing;

[0036] (4) Place the small porcelain boat with evenly mixed Se and S powders and another small porcelain boat with nanofiber precursors in the tube furnace, and place the small porcelain boats with evenly mixed Se and S powders close to At one end of the vent, raise the temperature at a rate of 5 °C / min to 300 °C for 2 hours; then increase the rate of temperature at 5 °C / min...

Embodiment 2

[0039] a FeS 2-x Se x Solid solution positive electrode material, its preparation method comprises the following steps:

[0040] (1) Add 1mmol iron oxalate and 0.4g PAN to 10ml DMF in sequence, and stir at 800r / min at 25°C for 12h to obtain a uniformly dispersed spinning solution;

[0041] (2) By electrospinning, the spinning solution obtained in step (1) is spun into nanofibers distributed with iron precursors, and then heated to 1000°C at a heating rate of 10°C / min for 3 hours, and samples are collected after cooling;

[0042] (3) Ball mill 3mmol S powder and 1.5mmol Se for 12h to obtain a homogeneous mixture;

[0043] (4) Place the small porcelain boat with evenly mixed Se and S powder and another small porcelain boat with nanofiber precursor in the tube furnace, and the small porcelain boat with evenly mixed Se and S powder is close to the ventilation At one end of the mouth, raise the temperature at a rate of 5 °C / min to 300 °C for 2 hours; then increase the rate of te...

Embodiment 3

[0046] a FeS 2-x Se x Solid solution positive electrode material, its preparation method comprises the following steps:

[0047] (1) Add 1mmol iron oxalate and 0.5g PAN to 10ml DMF in sequence, and stir at 800r / min for 12h at 25°C to obtain a uniformly dispersed spinning solution;

[0048] (2) Spin the spinning solution obtained in step (1) into nanofibers distributed with iron precursors by electrospinning, raise the temperature to 1000° C. for 3 hours at a heating rate of 10° C. / min, and collect samples after cooling;

[0049] (3) Ball mill 4mmol S powder and 1mmol Se for 12h to obtain a homogeneous mixture;

[0050] (4) Place the small porcelain boat with evenly mixed Se and S powder and another small porcelain boat with nanofiber precursor in the tube furnace, and the small porcelain boat with evenly mixed Se and S powder is close to the ventilation At one end of the mouth, the temperature was raised to 225°C at a heating rate of 5°C / min and kept for 2 hours; then the t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com