Excessive glue scraping equipment and glue scraping method for processing and pasting touch screen

A touch screen and squeegee technology, which is applied to coatings, devices that apply liquid to the surface, etc., can solve the problems of difficulty in squeegee, unsatisfactory effect of squeegee, general softening effect of glue, etc., and achieves ideal squeegee effect, Guarantee the effect of squeegee effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

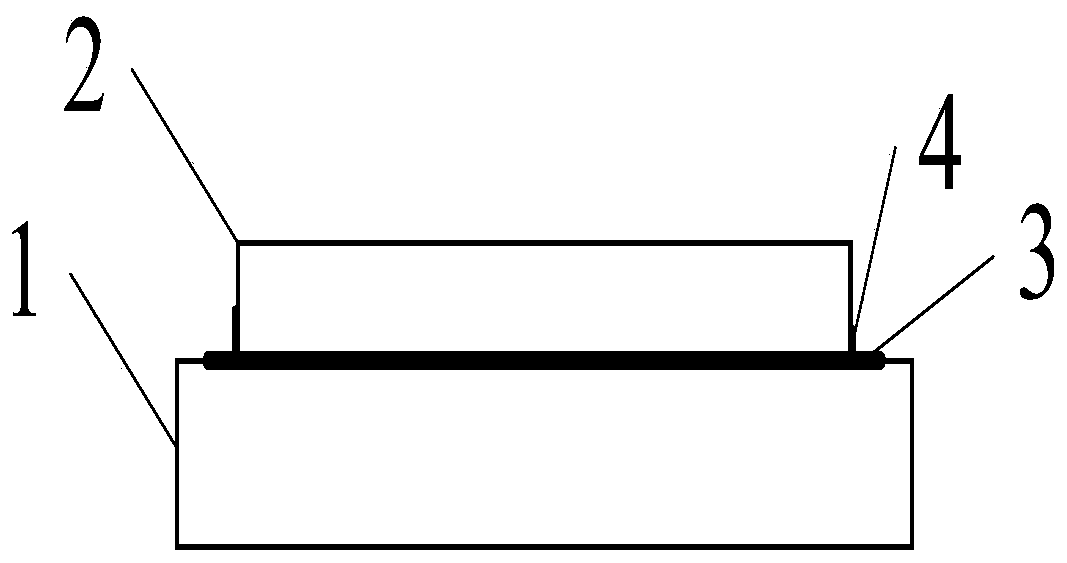

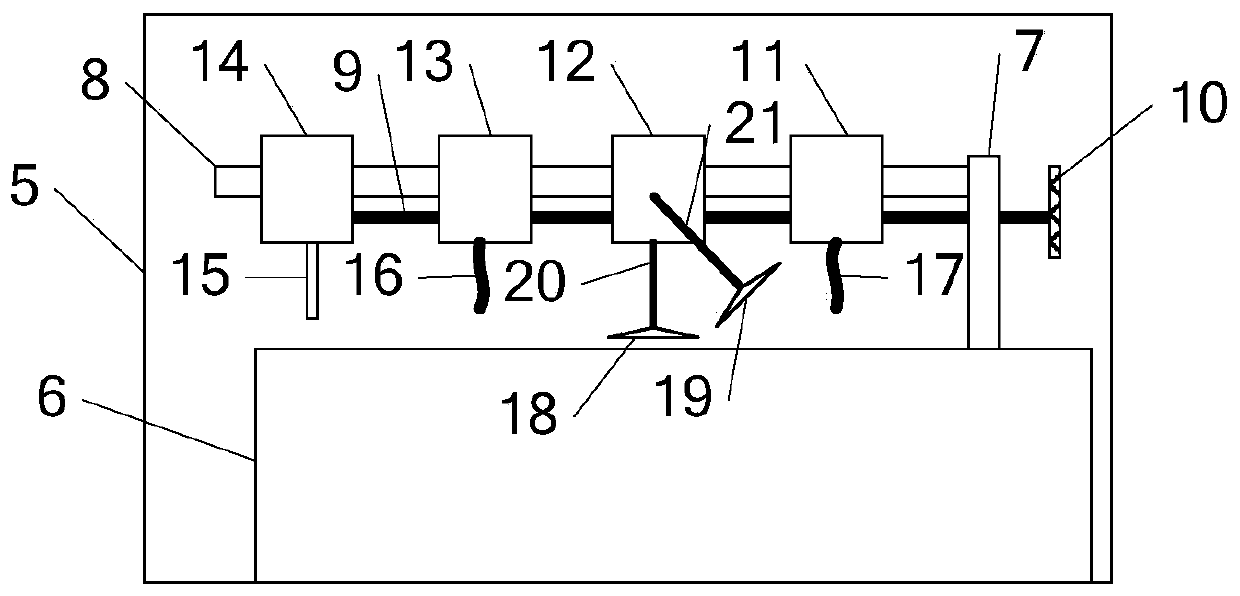

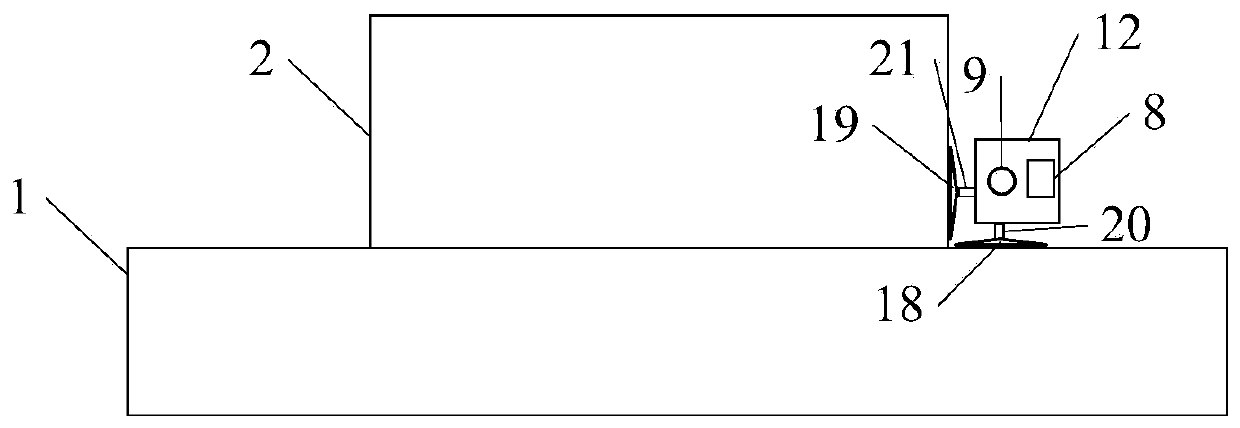

[0084] Please refer to Figure 2-Figure 5 , Embodiment 1 of the present invention provides a touch screen processing and bonding overflow glue scraping equipment, the equipment includes:

[0085] Sealed operating room 5, operating table 6, first vertical fixed plate 7, guide rail 8, guide rod 9, handle 10, first slider 11, second slider 12, third slider 13, fourth slider 14 , the first vacuum cleaner 23, the second vacuum cleaner, the first scraper 18, the second scraper 19, the first connecting rod 20, the second connecting rod 21, the hot air blower 22;

[0086]The operation table is located in the sealed operation room, and there is an operation area for fixing the touch screen to be scraped on the operation table; the first slider, the second slider, the third slider and the fourth slider are all sleeved on the guide rail. The first slide block, the second slide block, the third slide block and the fourth slide block can all slide on the guide rail, the first vertical fix...

Embodiment 2

[0091] In the second embodiment, the equipment in this embodiment, on the basis of the first embodiment, the lengths of the first connecting rod and the second connecting rod can be adjusted. Please refer to Figure 6 , Figure 6 It is a structural schematic diagram of the first connecting rod. The first connecting rod and the second connecting rod have the same structure. The first connecting rod includes a second cylinder 24, a first round rod 25 and several first tightening screws 26. The second round One end of the cylinder is connected to the handle of the corresponding scraper, one end of the first round rod is inserted into the second cylinder from the other end of the second cylinder, the other end of the first round rod is fixedly connected with the second slider, and the second cylinder is along the circumference The direction is evenly provided with several first tightening screw holes, the length of the first round rod inserted into the second cylinder can be adju...

Embodiment 3

[0093] In the third embodiment, the equipment in this embodiment, on the basis of the first embodiment, please refer to Figure 7 , the device also includes: a first fixed vertical bar 27, a first fixed horizontal bar 28, a first cylinder 29, a first fixed nail 30 and a first horizontal fixed plate 31; the lower end of the first fixed vertical bar is fixed on the console In the non-operating area above, one end of the first fixed horizontal bar is fixedly connected with the upper end of the first fixed vertical bar, and the other end of the first fixed horizontal bar is fixedly connected with the side of the first cylinder, and the two ends of the first cylinder are open The lower end of the first fixing nail passes through the first cylinder and extends from the lower end of the first cylinder to be fixedly connected to the upper surface of the first horizontal fixing plate, and the first cylinder is screwed to the first fixing nail. Wherein, the first fixed vertical bar 27, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com