High-voltage direct-current cable insulating layer charge injection quantity characterization method

A charge injection, high-voltage DC technology, applied in the measurement of electrical variables, measuring devices, instruments, etc., can solve the problems of inability to distinguish the amount of charge injected on the surface of the insulating layer, unable to characterize the charge injection of the semiconducting layer, etc., to simplify the characterization method. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] Objective: Under the conditions of pressurization temperature T1 and pressurization voltage E1, the injection amount of internal space charge and surface charge after pressurization t1 of two identical first sample and second sample.

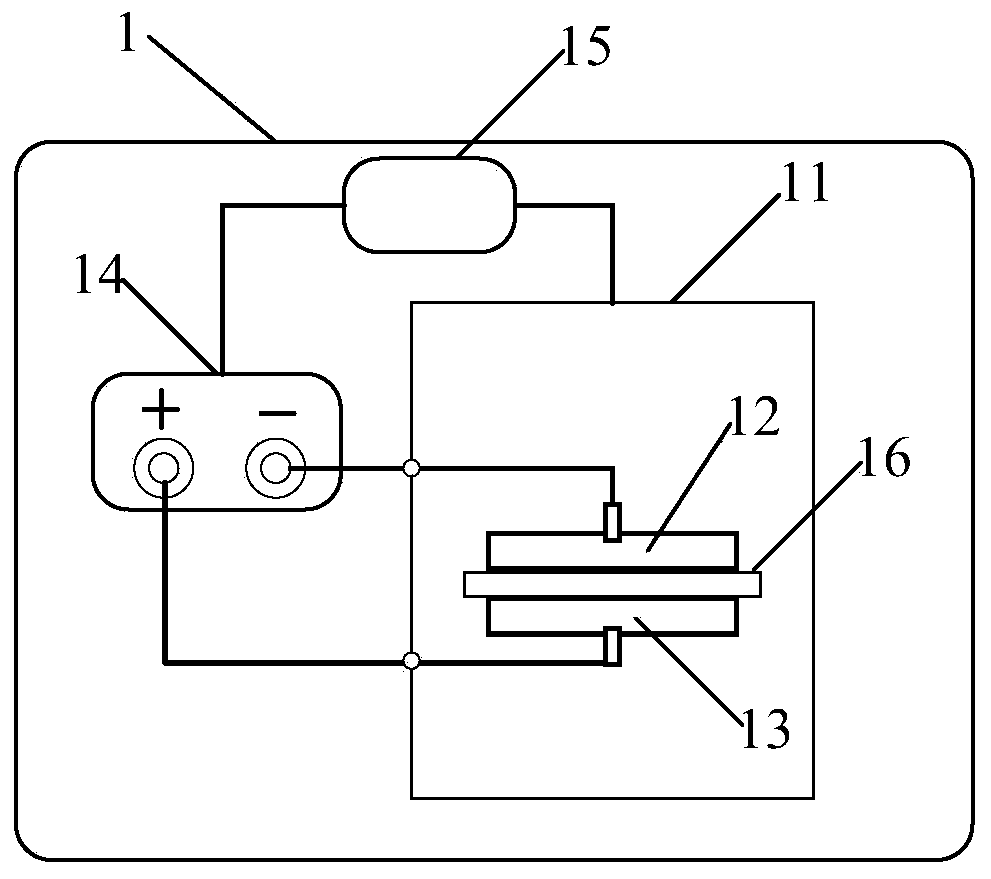

[0062] Polarization process: put the first sample and the second sample between the first upper electrode 12 and the first lower electrode 13 of the polarization device 1, adjust the internal temperature of the first temperature control box 11 to T1, when the temperature When the set temperature is reached, the high voltage direct current source 14 is connected to pressurize the sample for polarization and charge injection. The pressurization time is t1, and the pressurized voltage of the high voltage direct current source 14 is E1.

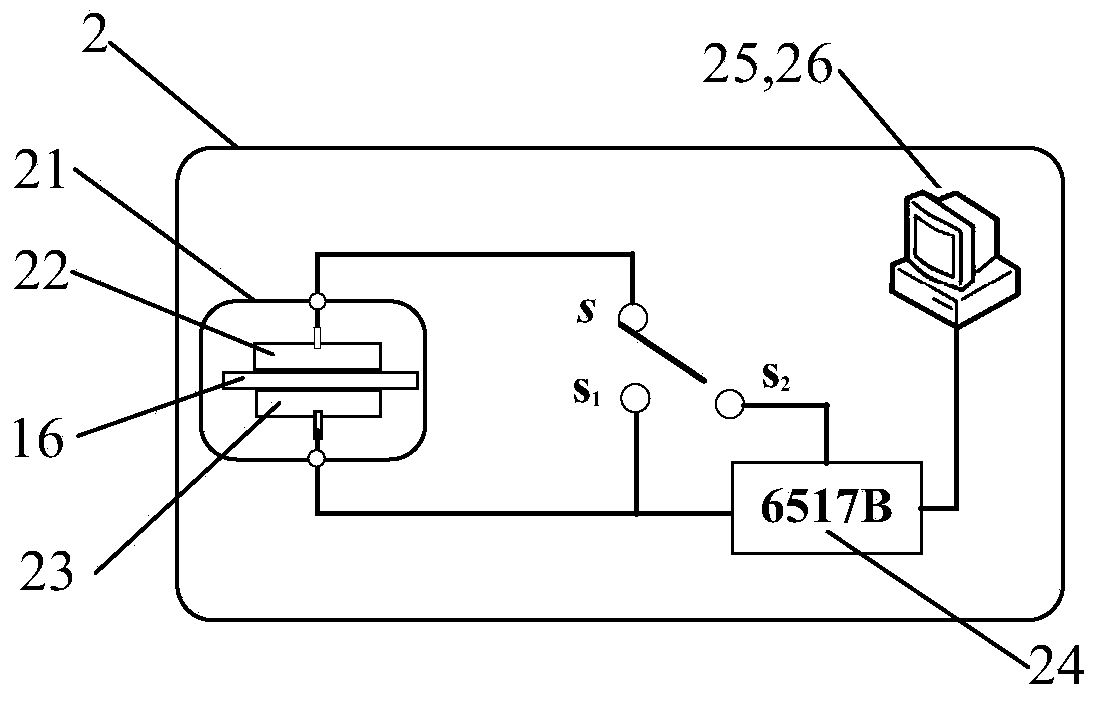

[0063] Depolarization process: after the sample is cooled to room temperature, move the first sample between the second upper electrode 22 and the second lower electrode 23 of the thermal stimulation current ...

Embodiment 2

[0066] Objective: Under the conditions of pressurization temperature T2 and pressurization voltage E2, the amount of internal space charge injection and surface charge injection after pressurization t2 of two identical samples, the third sample and the fourth sample.

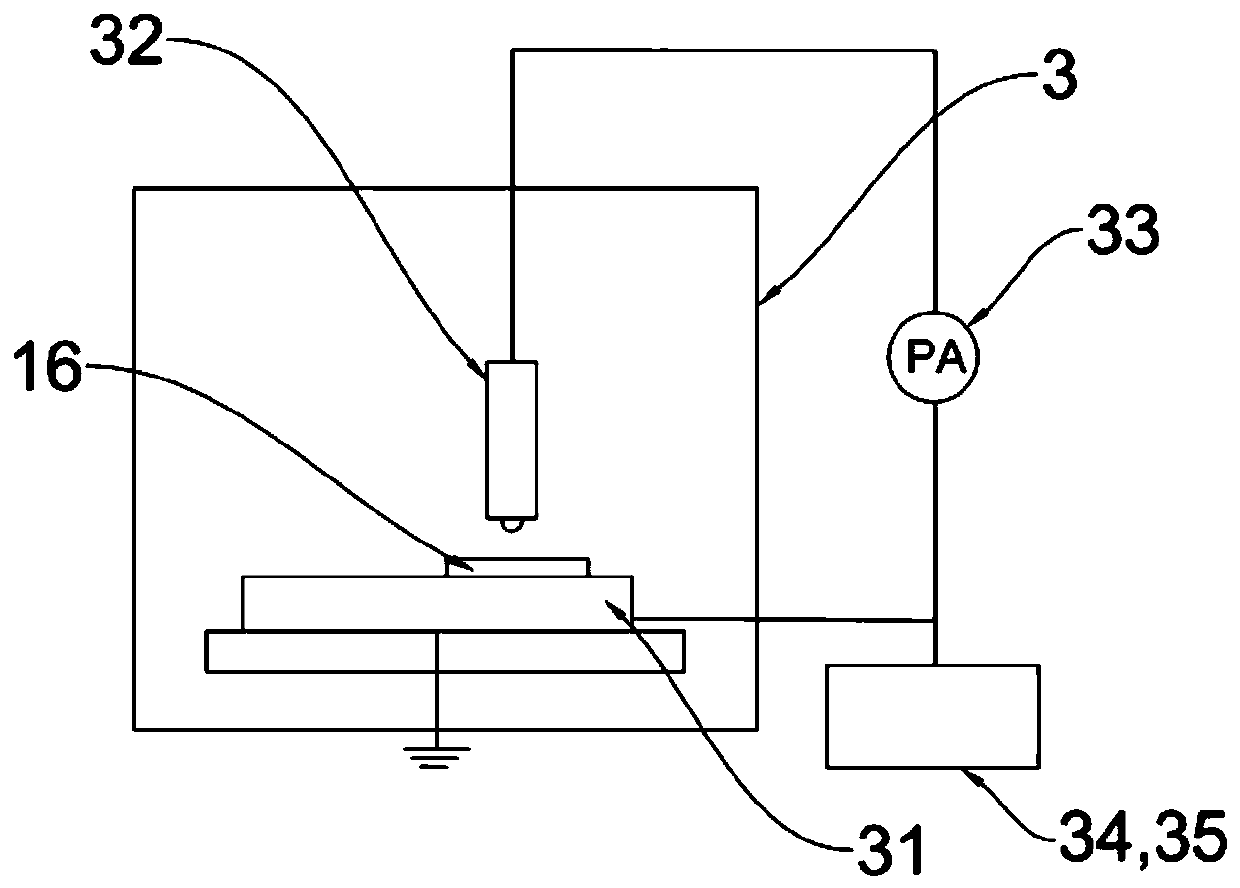

[0067] Polarization process: put the third sample and the fourth sample into the second position opposite to the gate electrode 42 on the ground electrode 31 of the integrated device 4, and adjust the internal temperature of the third temperature control box 41 of the integrated device 4 to T2 , when the temperature reaches the set temperature, connect the high-voltage direct current source 14 to pressurize the sample, the pressurization time is t2, and the pressurized voltage of the high-voltage direct current source 14 is E2.

[0068] Depolarization process: after the sample is cooled to room temperature, move the third sample into the thermal stimulation current testing system 2 between the second upper electr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com