Mandrel special for processing slender and thin-walled parts

A technology for mandrels and parts, applied in the field of special mandrels, can solve the problems of difficult clamping, affecting machining accuracy, clamping deformation, etc., to achieve the effects of simple clamping and disassembly, improving positioning accuracy and reducing deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention is further described below in conjunction with accompanying drawing:

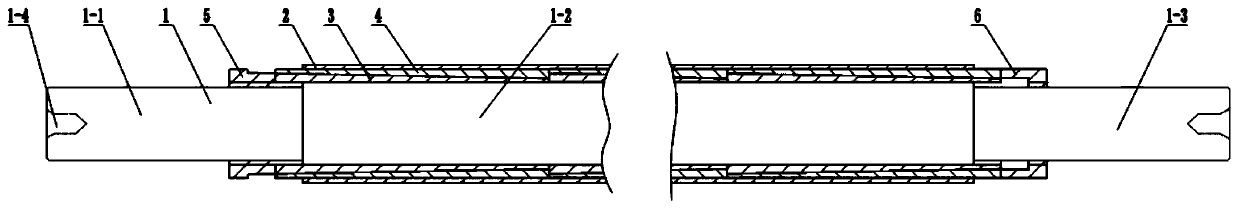

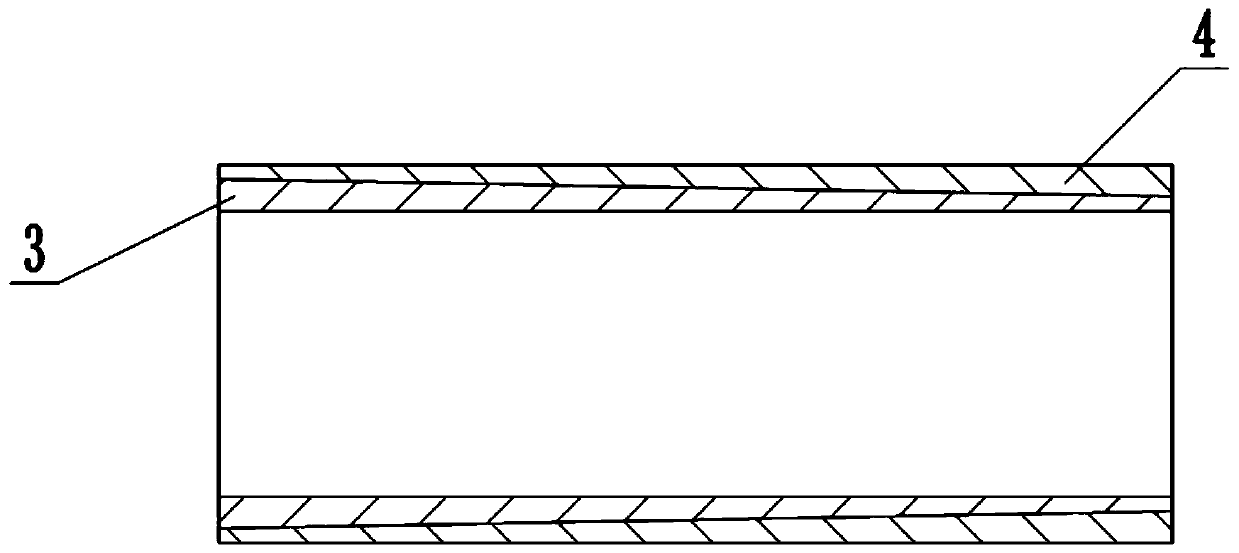

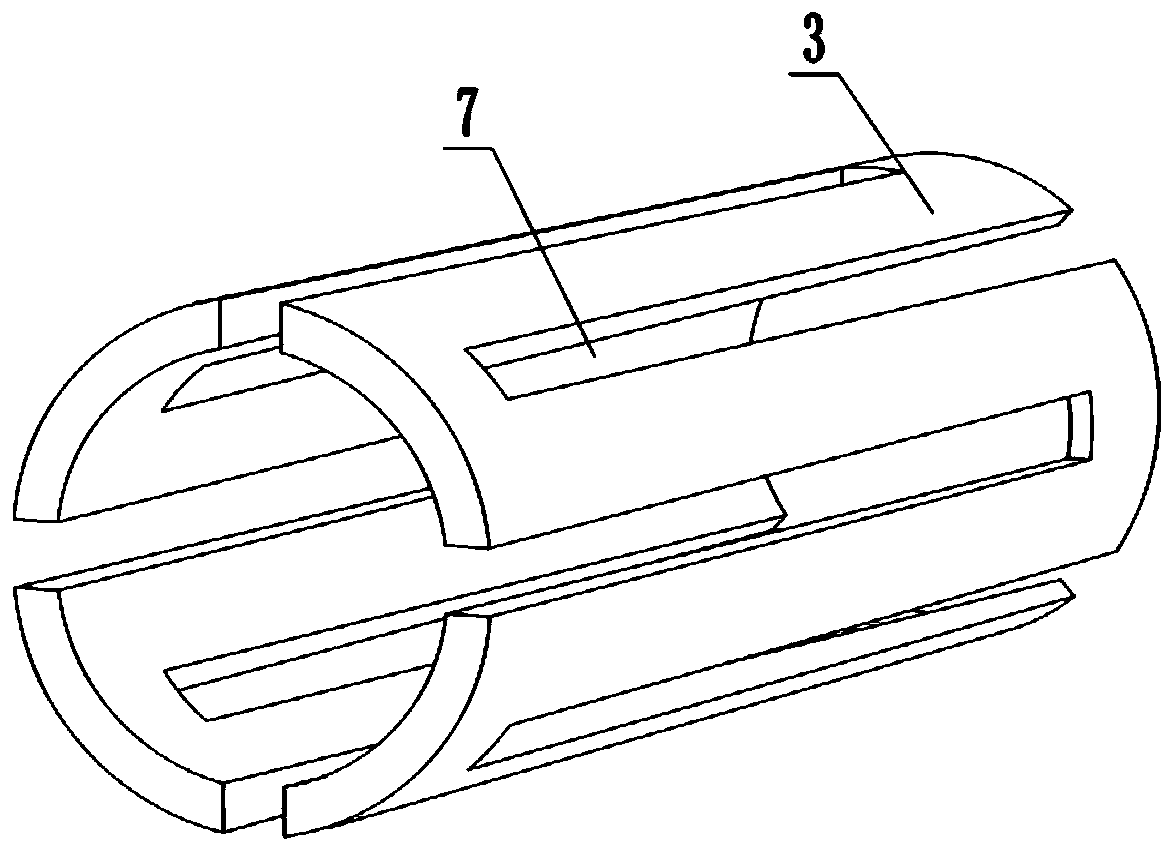

[0023] see Figure 1-8 , a special mandrel for processing slender and thin-walled tubular parts, comprising a mandrel body 1, the mandrel body 1 is a solid structure, and the mandrel body 1 includes a left end 1-1, a middle section 1-2 and a right end 1 -3, the left end 1-1, the middle section 1-2 and the right end 1-3 are cylinders, the centerlines of the left end 1-1, the middle section 1-2 and the right end 1-3 are coaxial, and the left end The diameter of 1-1 is equal to the diameter of the right end 1-3 and is smaller than the diameter of the middle section 1-2; the left end 1-1 is provided with a left fastening device 5, and the right end 1-3 of the mandrel is provided with a right Fastening device 6; the mandrel body 1 is coaxially provided with several sections of elastic sleeves, the elastic sleeves include inner elastic sleeves 3 and outer elastic sleeves 4, and the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com