A kind of imitation shell mother-of-pearl layer material with layered structure and preparation method thereof

A layered structure, shell-like technology, applied in the field of bionics, can solve problems such as poor fracture toughness of cement-based materials, and achieve the effects of high fracture toughness and durability, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

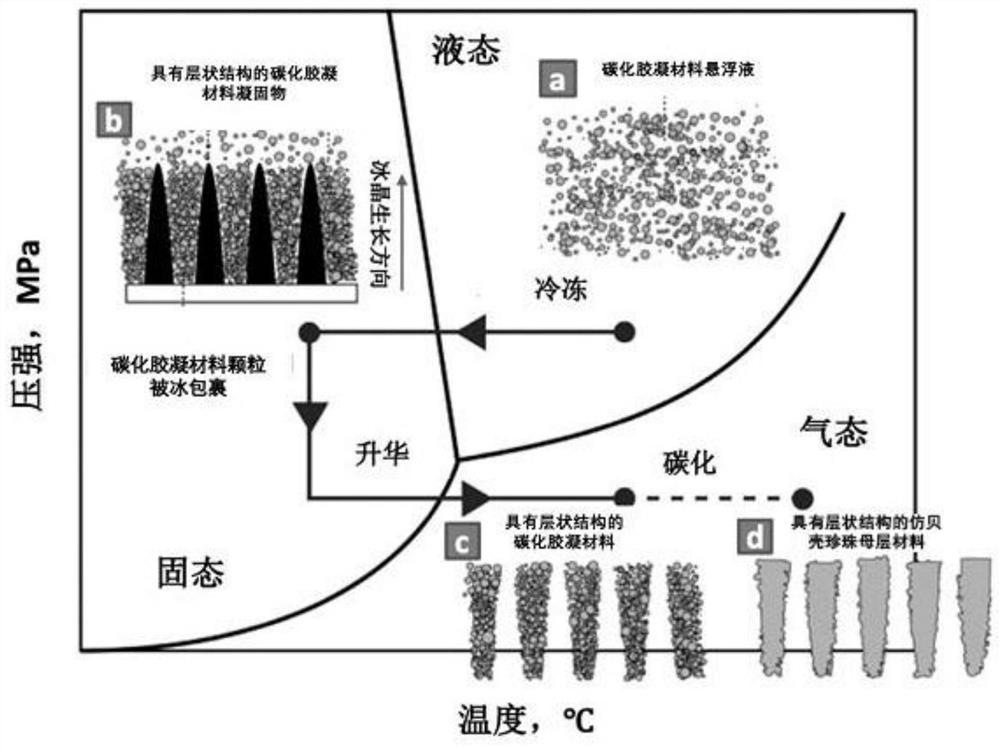

[0019] Such as figure 1 , the first aspect of the present invention provides a kind of preparation method of the imitation shell mother-of-pearl layer material with layered structure, comprises the following steps:

[0020] (a) uniformly mixing the carbonized gelling material with water at a water-solid ratio of 0.3 to 1.2 to obtain a suspension of the carbonized gelling material;

[0021] (b) processing the suspension of the carbonized cementitious material by a freezing casting process to obtain a solidified product of the carbonized cementitious material with a layered structure;

[0022] (c) freeze-drying the above-mentioned solidified carbonized gelling material with a layered structure to obtain a carbonized gelling material with a layered structure;

[0023] (d) Carrying out carbonization and hardening of the above-mentioned carbonized cementitious material having a layered structure to obtain a shell-like mother-of-pearl layer material having a layered structure.

[...

Embodiment 1

[0040] (1) 20g γ-C 2 S is uniformly mixed with 6g of water to obtain a suspension of carbonized gelling material;

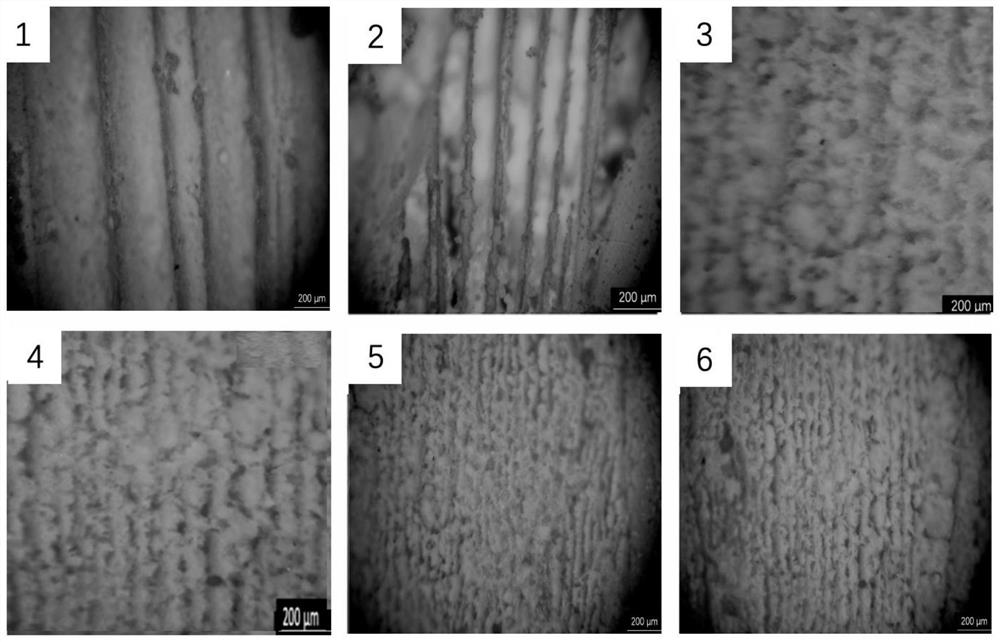

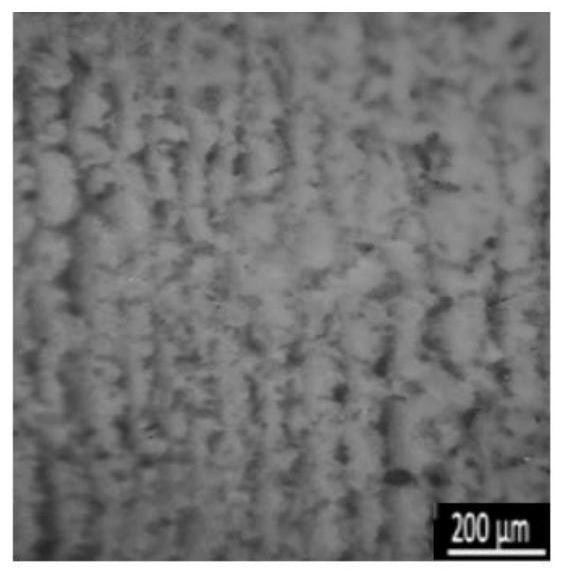

[0041](2) Place the prepared carbonized gelling material suspension in the freezing chamber of the freezing casting machine for one-way freezing, and cool it down to -60°C at a freezing rate of 1°C / min at room temperature, and the freezing time of the whole process is 1.5 h, obtaining a solidified carbonized cementitious material with a layered structure;

[0042] (3) Place the above-mentioned solidified carbonized gelling material with a layered structure in a freeze dryer for freeze-drying to obtain a carbonized gelling material with a layered structure; wherein, the freeze-drying temperature is -5°C, and the freeze-drying time is 6h, the relative vacuum is -0.1MPa

[0043] (4) Place the above-mentioned carbonized gelling material with a layered structure in the environment of passing water vapor and carbon dioxide gas to carry out carbonization and hardening...

Embodiment 2

[0045] (1) 20g γ-C 2 S is uniformly mixed with 10 g of water to obtain a suspension of carbonized gelling material;

[0046] (2) Place the prepared carbonized gelling material suspension in the freezing chamber of the freezing casting machine for one-way freezing, and cool it down to -60°C at a freezing rate of 1°C / min at room temperature, and the freezing time of the whole process is 1.5 h, obtaining a solidified carbonized cementitious material with a layered structure;

[0047] (3) Place the above-mentioned solidified carbonized gelling material with a layered structure in a freeze dryer for freeze-drying to obtain a carbonized gelling material with a layered structure; wherein, the freeze-drying temperature is -5°C, and the freeze-drying time is 6h, the relative vacuum is -0.08MPa

[0048] (4) Place the above-mentioned carbonized gelling material with a layered structure in the environment of passing water vapor and carbon dioxide gas to carry out carbonization and harde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com