Natural mineral soil conditioning nutritional agent as well as preparation method and application thereof

A technology of soil conditioning and minerals, applied in application, soil preparation methods, calcium fertilizers, etc., can solve the problems of cumbersome operation and high cost, and achieve the effect of simple preparation method, low cost, and improved physical and chemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

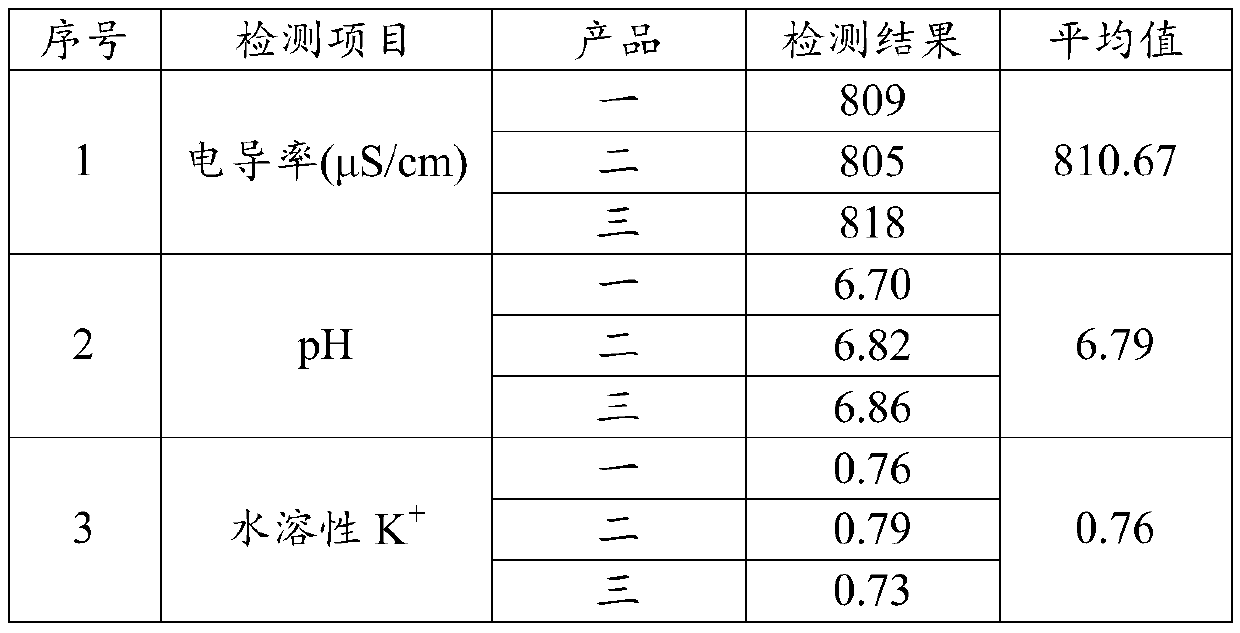

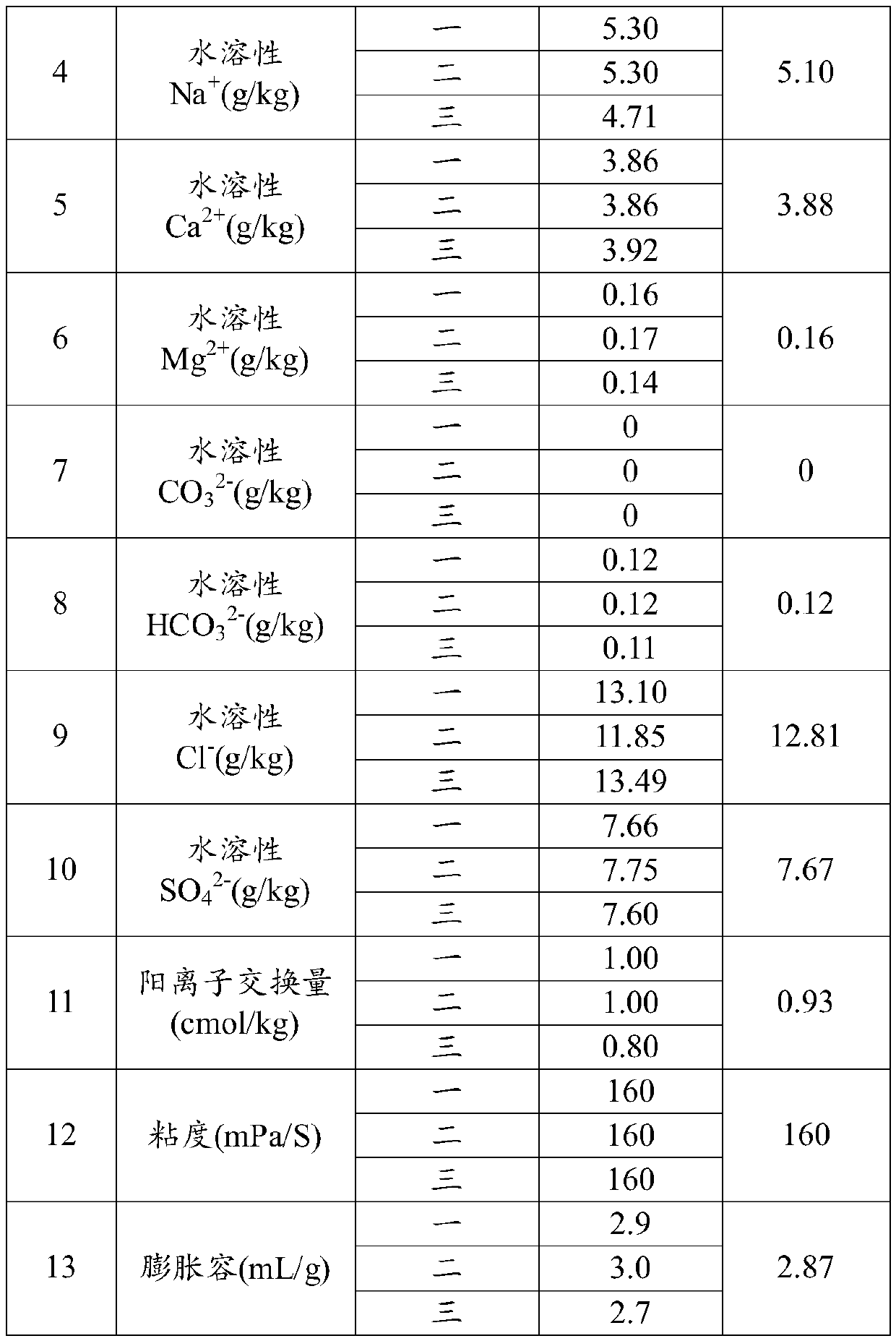

Embodiment 1

[0025] Following three kinds of formulas are the preferred formulas of mineral matter of the present invention, specifically:

[0026] Product 1 is composed of the following components in parts by weight: 52 parts of minerals, 4 parts of hydrophobic carbohydrate fatty acids, 8 parts of sodium hydroxymethylcellulose, 10 parts of cellulose-based activated carbon, and 70 parts of water; the minerals are natural gypsum ore A mixture of attapulgite and attapulgite; the mass ratio of natural gypsum ore to attapulgite is 3:1.

[0027] Product 2 consists of the following components in parts by weight: 55 parts of minerals, 6 parts of epoxy resin, 10 parts of acrylic acid, 15 parts of cellulose-based activated carbon, and 75 parts of water; the minerals are a mixture of natural gypsum ore and attapulgite, natural gypsum The mass ratio of ore to attapulgite is 3:1.

[0028] Product three consists of the following parts by weight: 58 parts of minerals, 8 parts of epoxy resin, 13 parts o...

Embodiment 2

[0038] The three products in Example 1 were applied to the planting of rice in saline-alkali soil. The experimental group was the planting field using the mineral material product 1, product 2 and product 3 of the present invention, and the control group was the planting field that did not apply the mineral material of the present invention. Ueda; The performance parameters of the saline-alkali land were tested before and after the experiment, and the rice yields in the experimental group and the control group were recorded after the experiment.

[0039] General situation of the test field: The soil salinization in the test field is serious, and the pH value is above 8.0, and even above 8.5 in serious cases. The total salt content of the 0-40cm topsoil is 2.06%, and the conductivity is 7.76, which is a typical saline soil. The test crop was rice.

[0040] Field test results: the crop emergence rate and output after the improvement of the mineral material of the present inventi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com