Flow pattern regulator for oil-based drilling fluid and preparation method

A flow pattern regulator, oil-based drilling fluid technology, applied in chemical instruments and methods, drilling compositions, etc., can solve the problem that the rheological properties of the system are difficult to adjust, the oil-based drilling fluid is thickened at high temperature, and the shearing effect is poor. and other problems, to achieve the effect of improving drilling quality and speed, reducing viscosity and chemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

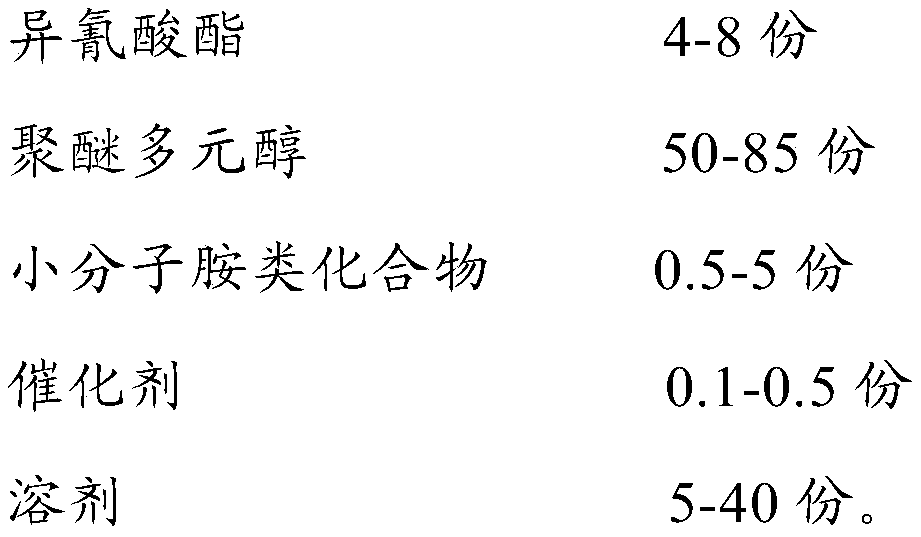

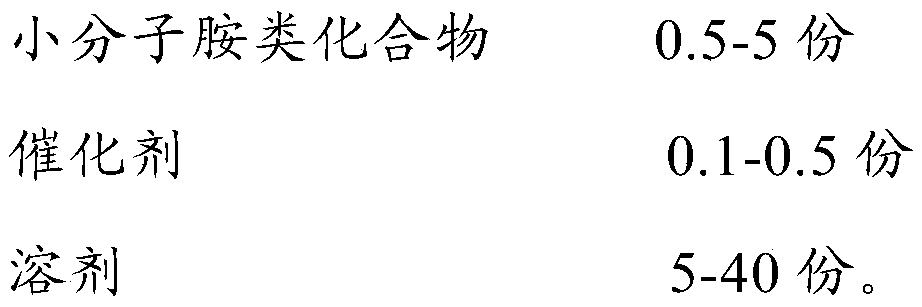

[0028] The present embodiment provides a flow conditioner for oil-based drilling fluids, including the following raw materials by weight: 7.5 kg of isocyanate (MDI-50, Wanhua Chemical), 75 kg of polyether polyol (C2020, Wanhua Chemical), Molecular amine compound (p-phenylenediamine, Shanghai Bangcheng Chemical) 3kg, catalyst (organotin, T12, American Gas Chemical) 0.1kg, 14.4kg solvent (150# solvent oil, Wuxi Yongzhen).

[0029] Add 75kg of polyether polyol and 14.4kg of solvent into the reaction kettle, heat up to 130°C under vacuum for 2 hours with high-speed stirring; reduce the temperature to below 50°C, add 3kg of small molecular amine compounds, and stir for 0.5 hours; Slowly add 7.5kg of isocyanate while stirring, react for 1 hour, then heat up to 80°C and stir to react for 1 hour; add 0.1kg of catalyst, continue to stir and react for 2 hours; cool to below 50°C, and discharge to obtain the product.

Embodiment 2

[0031] The present embodiment provides a flow conditioner for oil-based drilling fluid, which includes the following raw materials by weight: 4.8 kg of isocyanate (TDI, Cangzhou Dahua), 54.2 kg of polyether polyol (DL-1000D, Shandong Dongda), Small molecular amine compound (diaminodiphenyl ether, Nantong Runfeng Petrochemical) 0.5kg, catalyst (organic bismuth, Bicat8118, American leading chemical) 0.5kg, 40kg solvent (5# white oil, Maoming Petrochemical)

[0032] Add 54.2kg of polyether polyol and 40kg of solvent into the reaction kettle, heat up to 100°C with high-speed stirring and dehydrate for 4 hours under vacuum conditions; reduce the temperature to below 50°C, add 0.5kg of small molecular amine compounds, and stir for 10 minutes; then Slowly add 4.8kg isocyanate while stirring, react for 2 hours, then heat up to 60°C and stir for 2 hours; add 0.5kg of catalyst, continue stirring for 1 hour; cool to below 50°C, and discharge to obtain the product.

Embodiment 3

[0034] This embodiment provides a flow conditioner for oil-based drilling fluid, including the following raw materials by weight: 7kg of isocyanate (IPDI, Covestro), 74kg of polyether polyol (C2020, Wanhua Chemical), and 74kg of small molecular amines. Compound (diaminodiphenyl ether, Shanghai Bangcheng Chemical) 5kg, catalyst (organic zinc, Bicat Z, Shanghai Deyin Chemical) 0.1kg, 13.9kg solvent (5# white oil, Maoming Petrochemical).

[0035] Add 74kg of polyether polyol and 13.9kg of solvent into the reaction kettle, heat up to 120°C under vacuum for 3 hours with high-speed stirring; reduce the temperature to below 50°C, add 5kg of small molecular amine compounds, and stir for 20 minutes; Slowly add 7kg of isocyanate while stirring, react for 2 hours, then heat up to 70°C and stir to react for 2 hours; add 0.1kg of catalyst, continue to stir and react for 2 hours; cool down to below 50°C, and discharge to obtain the product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com