Continuous temperature gradient heat treatment device and method for rod-shaped material

A heat treatment device and rod-shaped material technology, applied in the field of heat treatment, can solve the problems of large sample preparation, long experiment period, and heavy workload, and achieve the effects of preventing heat loss, improving experiment efficiency, and avoiding heat convection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

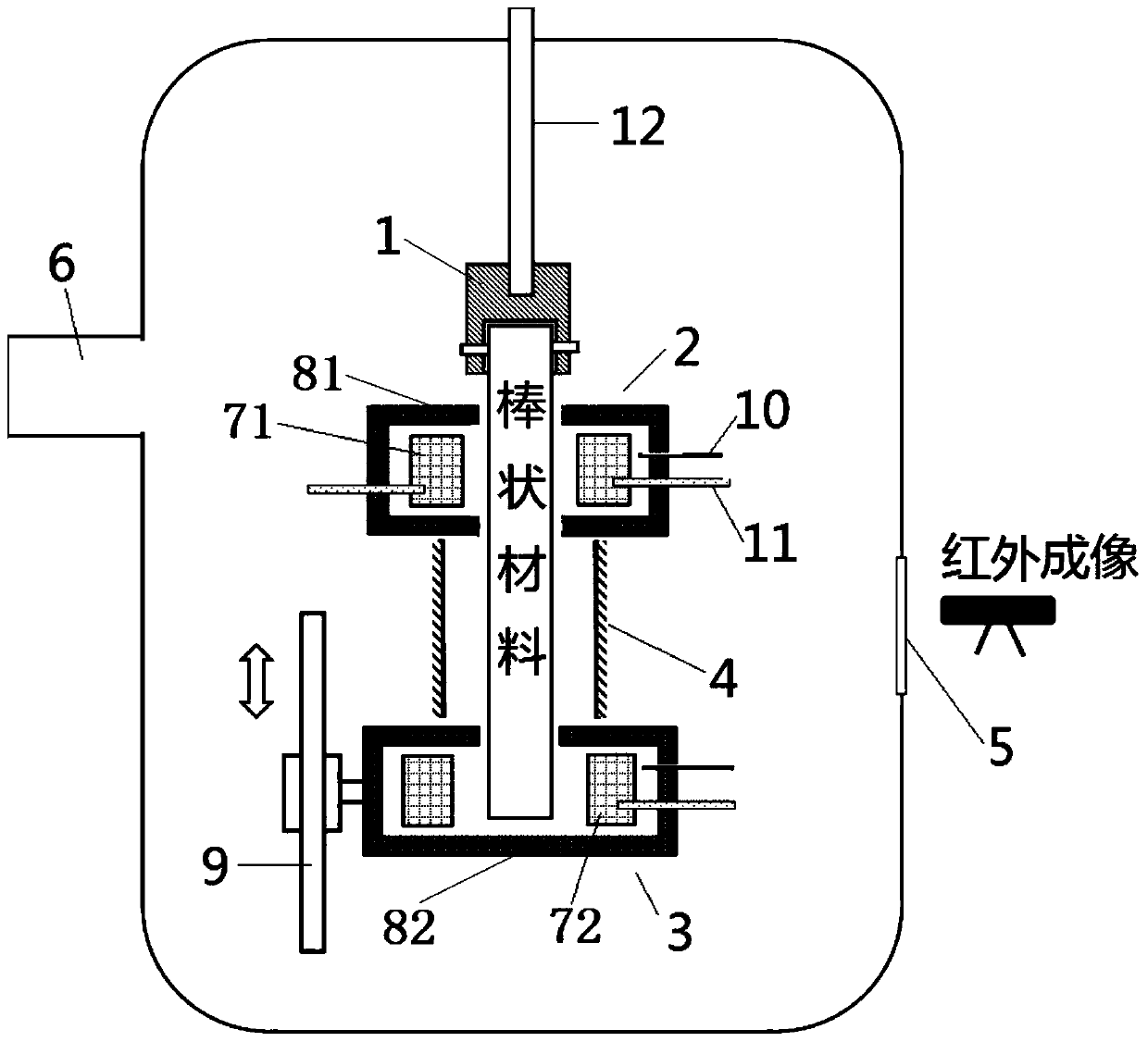

[0073] use figure 1 As shown in the device, the body of the furnace is provided with a water-cooled joint 1, an upper heating zone 2 (the size is ), the lower heating zone 3 (the size is ) and ring-shaped radiation screen 4 (material is Ta, thickness is 0.3mm, and a slit with a width of 1mm is provided along the axial direction); the ring-shaped radiation screen is located between the upper heating zone and the lower heating zone, and the ring-shaped radiation screen The distance between the upper end of the radiation screen and the bottom end of the upper heating zone is 0mm (that is, close contact), and the distance between the lower end of the annular radiation screen and the upper end of the lower heating zone is 0 mm (that is, close contact); An infrared thermal imaging temperature measurement window 5 and an air outlet 6 are provided; the upper heating zone 2 is provided with an upper heating rod 71 (specifically a silicon carbide rod) and an upper closed heat shield ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com