Restoration method of inverted arch in operating tunnel

A repair method and tunnel technology, which is applied in tunnels, tunnel linings, earthwork drilling and mining, etc., can solve the problem that the stress conditions of the upper lining structure cannot be effectively improved, the tunnel structure cannot be effectively ensured to be closed and ring-shaped, and the management risks and problems of construction units are increased. Cost and other issues, to achieve the effect of small concrete defect treatment workload, high concrete surface smoothness, and reduce the steps of intensive binding of steel bars

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

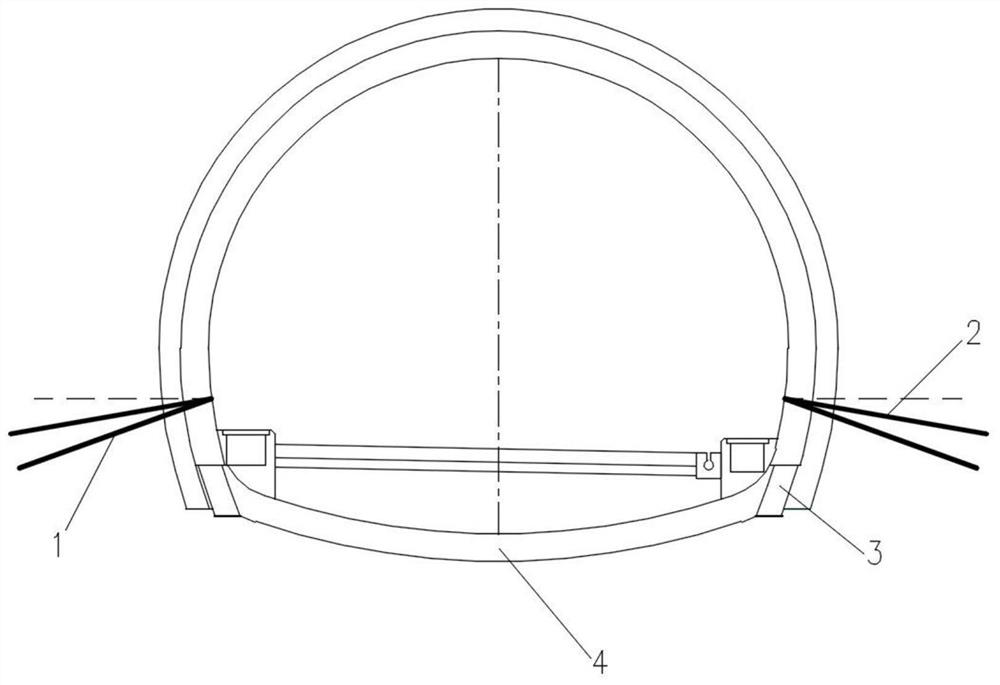

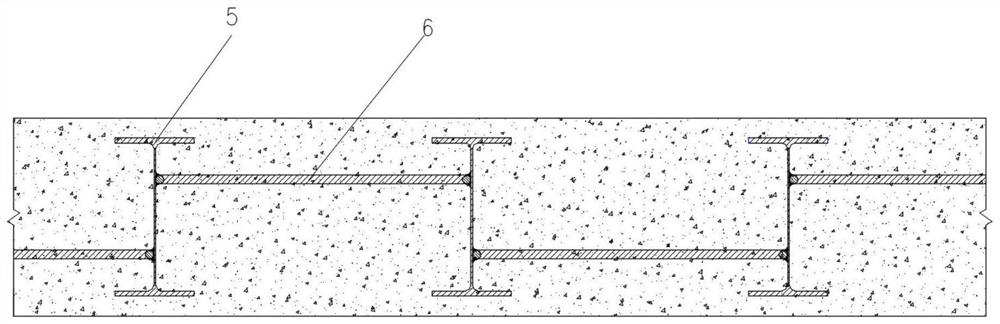

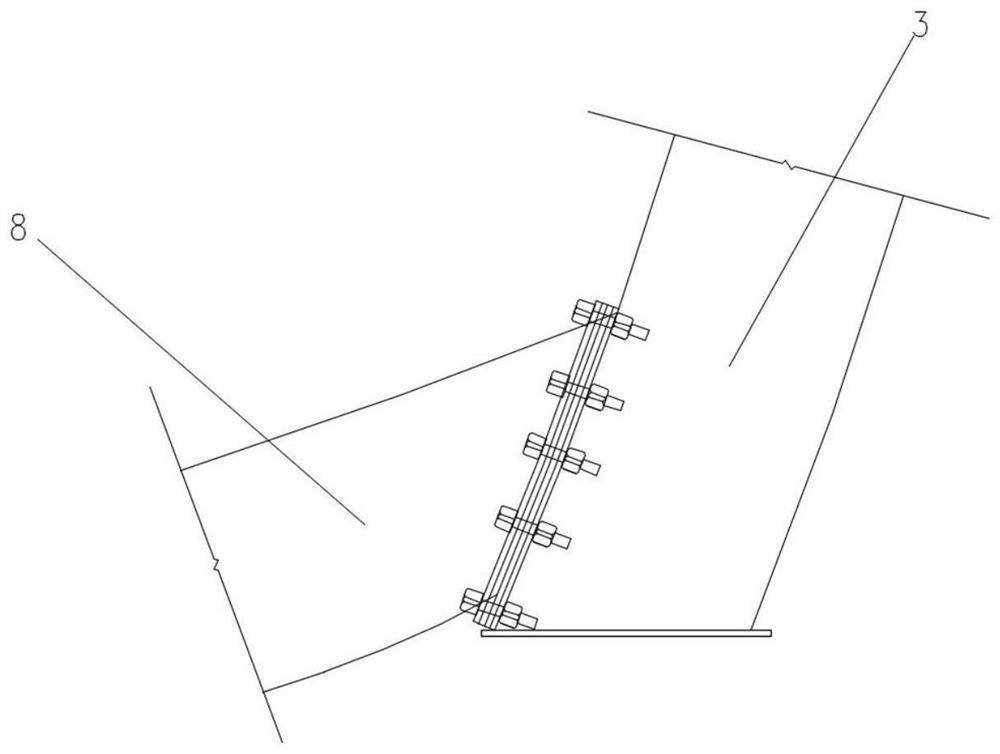

[0036] figure 1 It is a schematic diagram of the tunnel inverted arch structure of the present invention; figure 2 It is a sectional view of the H-shaped steel connecting reinforcement of the present invention; image 3 It is a schematic diagram of the connection structure between the erecting steel plate and the inverted arch; Figure 4 In order to erect a large sample of the steel plate, as shown in the figure, a method for repairing an invert of an operational tunnel includes the following steps: A: Drill a row of anchor pipe holes at the left and right arches of the invert, and then Install the lock-foot grouting anchor pipe into the anchor pipe hole and grout into the lock-foot grouting anchor pipe; B: After completing the grouting in step A, wait for the lock-foot grouting anchor pipe grouting strength to reach the qualified parameters and proceed sequentially Demolition of pavement structure, backfilling of inverts and demolition of inverts; C: Clearing and transport...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com