Experimental device for measuring single-oil-drop combustion temperature and flame structure under low-pressure condition

An experimental device and combustion temperature technology, which is applied in the direction of measuring devices, machine/structural component testing, thermometers, etc., can solve problems such as poor air tightness, damage to measurement objects, and no optical window, so as to improve the convenience of experiments , easy to repair and replace, good repeatable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

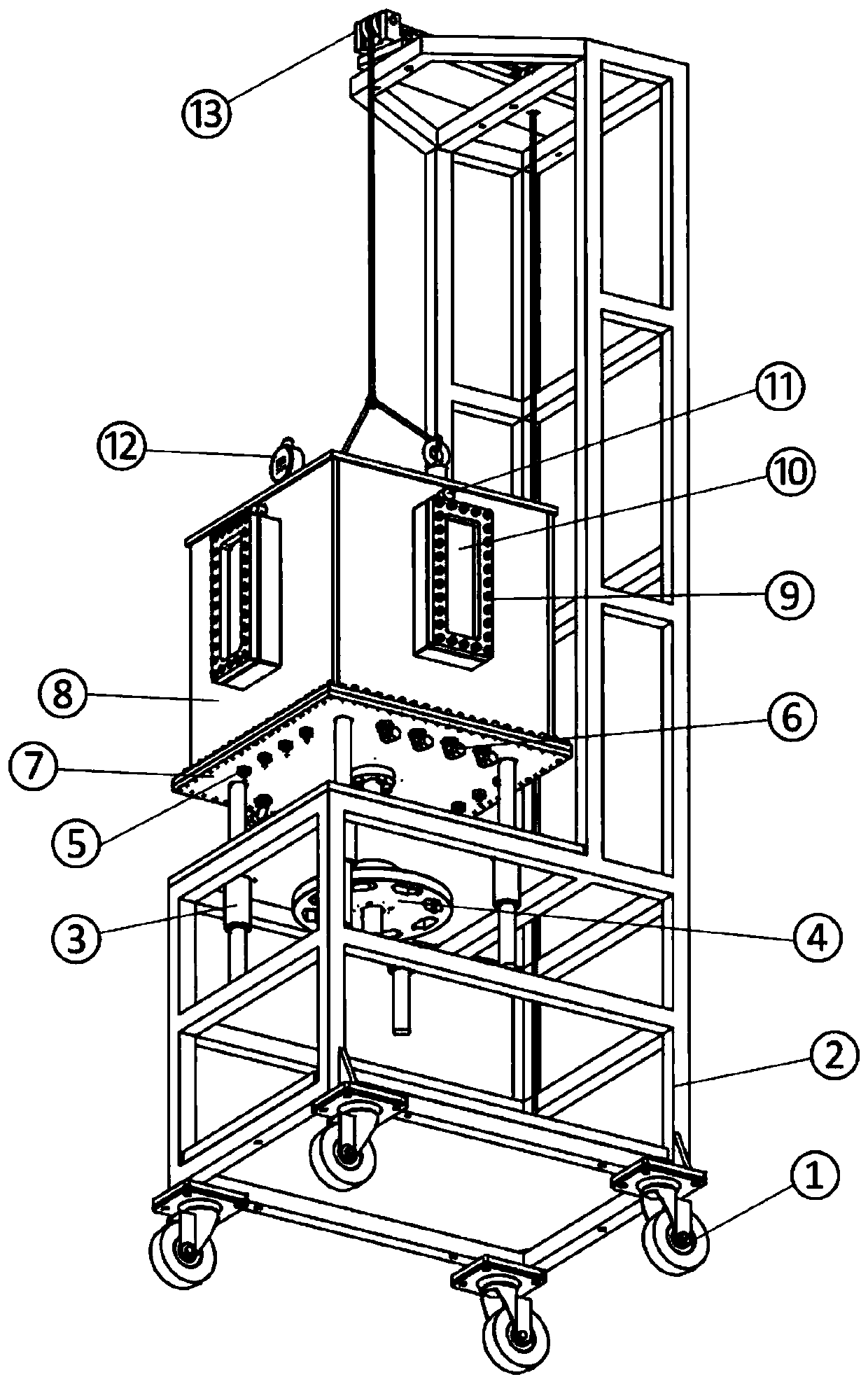

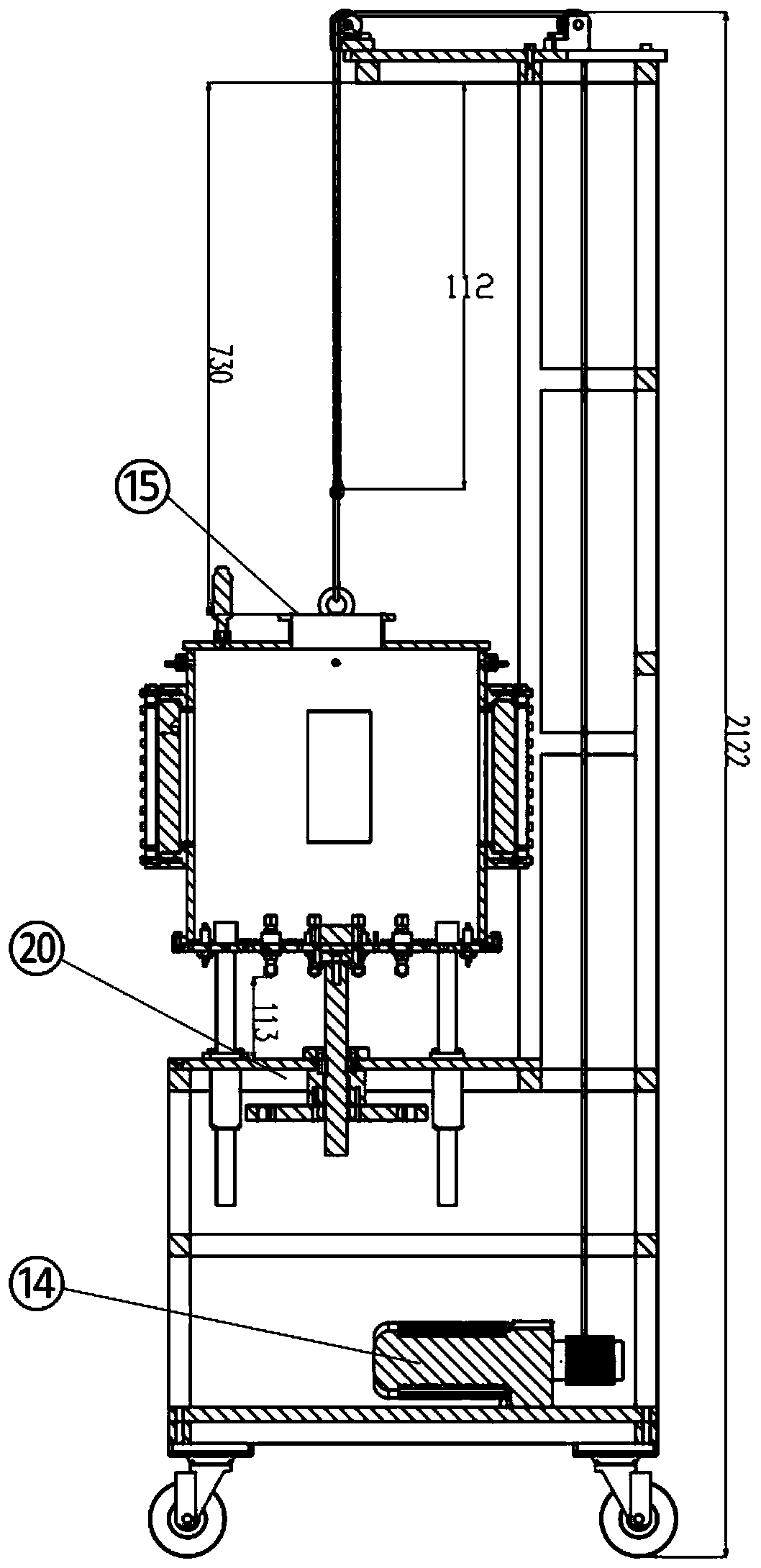

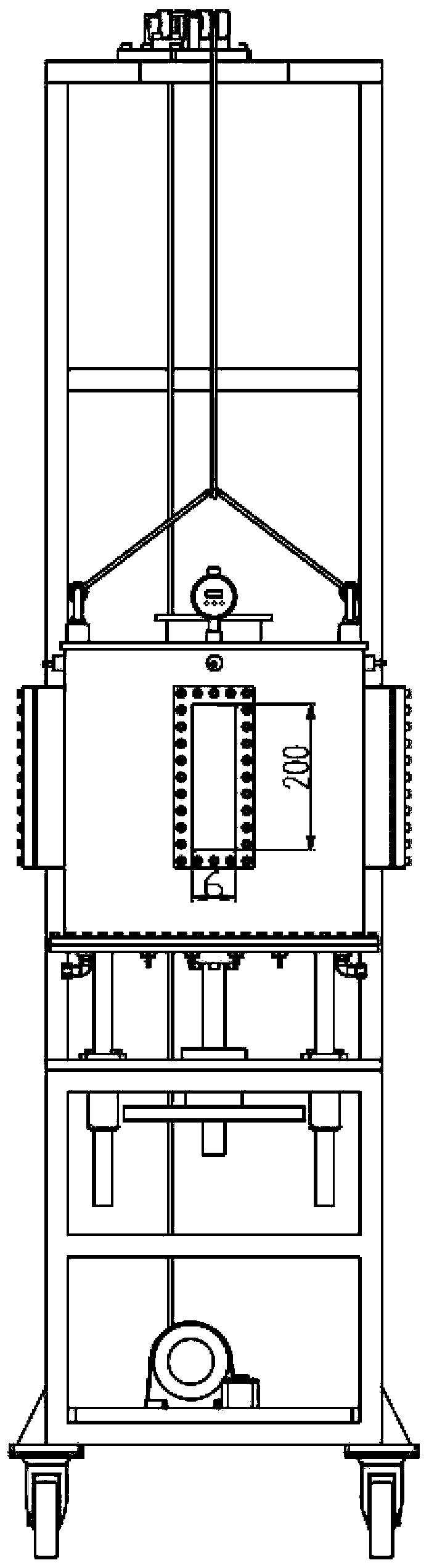

[0033] The experimental device for measuring the combustion temperature and flame structure of a single oil droplet under low pressure conditions according to the present invention will be described in detail below with reference to the accompanying drawings.

[0034] Such as Figure 1-5 As shown, the experimental device for measuring the combustion temperature and flame structure of a single oil droplet under low pressure conditions includes a movable support frame, which consists of two parts: a frame platform 2 and a vertical support, wherein the surface of the frame platform 2 is fixed with a platform panel 20 ; An electric hoist 14 is fixedly installed inside the frame platform 2; 4 universal wheels 1 with locking and fixing mechanisms are arranged at the bottom of the frame platform 2.

[0035] The low-pressure chamber 8 is used for the single oil droplet combustion test, and its structure is in the shape of a cube with an opening at the bottom. The bottom cover 7 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com