Method for evaluating thermal cracking starting temperature of heavy oil product

A technology of starting temperature and pyrolysis, which is applied in the direction of material inspection, weighing by removing certain components, and analysis by electron paramagnetic resonance, etc. It can solve bond breaking reaction, advance breaking temperature, calculate or predict heavy Problems such as the deviation of decomposition temperature of high-quality oil products, etc., to achieve the effect of simple and easy method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

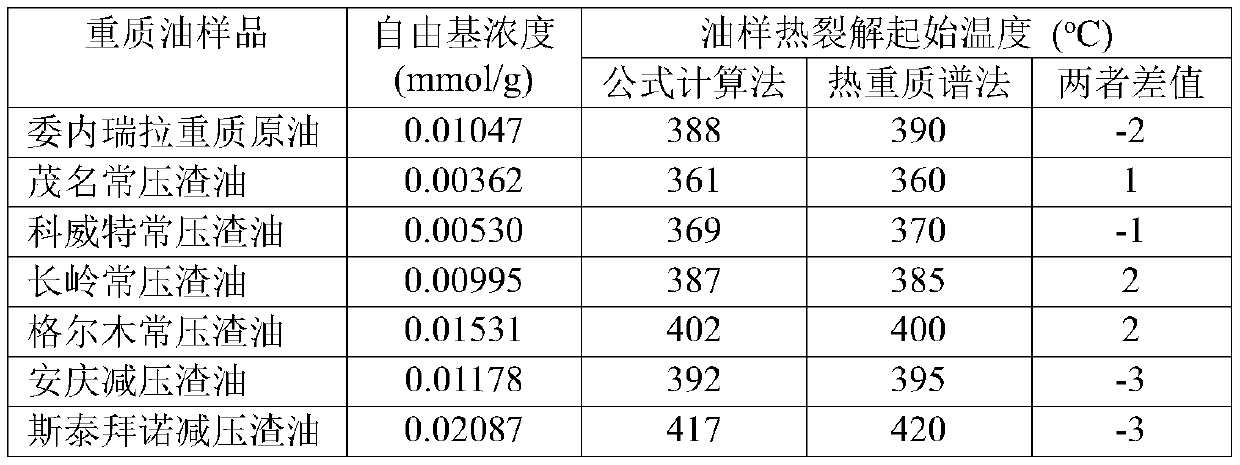

[0016] 1 kind of Venezuelan heavy crude oil, 4 kinds of atmospheric residues and 2 kinds of vacuum residues were tested for free radicals, 7 kinds of heavy oils were heated to 70±5°C under an inert atmosphere, and an open glass with an inner diameter of 2mm was used to measure the free radicals. Dip 10mg of the tubes respectively, and put the glass tube containing the oil to be tested into the paramagnetic tube to measure the concentration of free radicals. At the same time, use an open glass tube with an inner diameter of 2 mm to pick up 10 mg of heavy oil respectively, put the glass tube containing the oil to be tested into the thermogravimetry-mass spectrometry system, and heat it under an argon atmosphere with a heating rate of 5 °C / min. The test results are shown in Table 1.

[0017] Table 1 Test results of seven kinds of petroleum heavy oil

[0018]

Embodiment 2

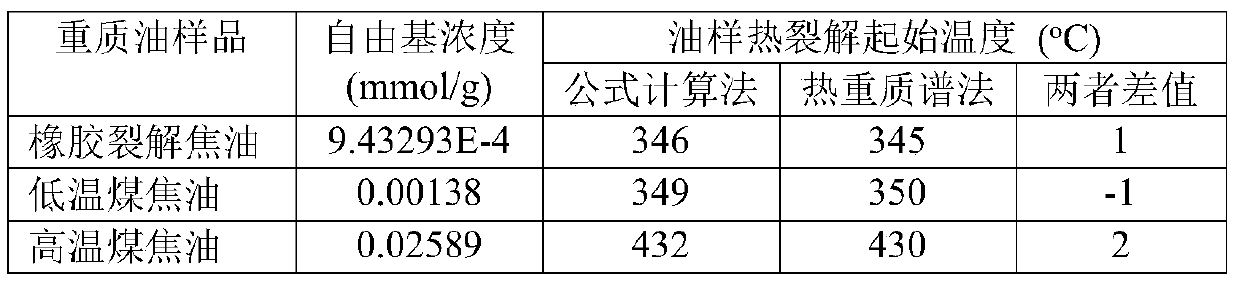

[0020] One rubber cracking tar and two coal tars were tested for free radicals, the method was the same as in Example 1, and the results are shown in Table 2.

[0021] Table 2 Test results of three kinds of tars

[0022]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com