A method of manufacturing a multilayer chip power inductor

A production method and technology of power inductors, which are applied in the manufacture of inductors/transformers/magnets, circuits, coils, etc., can solve the problems of limiting the saturation current of laminated power inductors, easy magnetization saturation, and poor DC superposition characteristics, and achieve low eddy current Effects of loss, high magnetic permeability, and high oxidation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] A kind of soft magnetic composite slurry, the preparation method of described soft magnetic composite slurry comprises the following steps:

[0040] The first step is pre-baking, respectively baking the iron-based alloy powder and ferrite powder at 80°C-130°C;

[0041] The second step is to disperse, add grinding medium to the ball mill, add 0.1-4.0wt% dispersant to the solvent, mix well, make A liquid and add it to the ball mill; take iron-based alloy powder and ferrite The powder is pre-mixed, and the pre-mixed powder is added to a ball mill tank for ball milling to make B liquid;

[0042] The third step is to make slurry, take 1-15wt% binder and 0.5-8wt% plasticizer to dissolve in the solution to make liquid C, add liquid C to the ball mill tank, and perform ball milling to make D slurry.

[0043] The iron-based alloy powder is selected from at least one of Fe-Si-Al, Fe-Si-Cr, and Fe-Cr-Al, with an average particle size of 2-30 μm, and the iron-based alloy powder i...

Embodiment 1

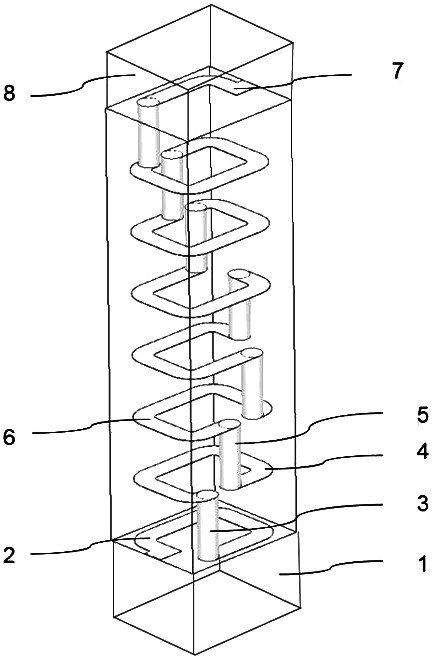

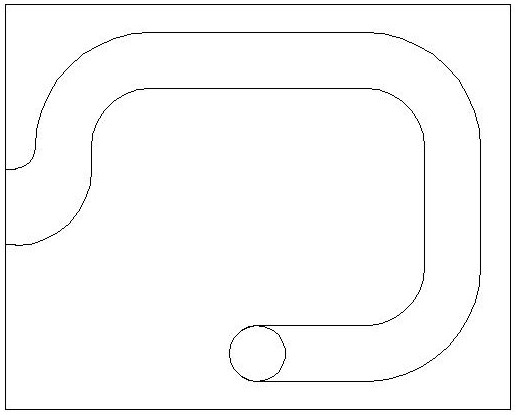

[0064] Embodiment 1: Reference figure 1 and Figure 15 , the present invention is mainly composed of coils 2-6, substrate 9 and terminal electrodes 10. The coils 2-6 are designed inside the base body 9, and the lower lead-out end 2 and the upper lead-out end 7 are respectively connected to both sides of the terminal electrode 10. The coils are connected by point posts to form spiral electrodes, and the DC resistance can be reduced by increasing the thickness of the coils.

[0065] In the present embodiment, the preparation method of the soft magnetic composite slurry of the present invention is as follows: take a certain amount of (NiZn)Fe 2 o 4 and Fe-Si-Cr powder, (NiZn)Fe2O4 accounts for 15wt% of the total mass of the powder, baked at 120°C for 12 hours to remove the adsorbed water in the powder. Among them, Si content in Fe-Si-Cr powder is 3-7wt%, Cr content is 3-7wt%, (NiZn)Fe 2 o 4 The average particle size is about 0.8-1.5 μm, and the average particle size of Fe-S...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com