Filling method of SiC epitaxial deep trench

A filling method and deep trench technology, applied in semiconductor devices, electrical components, circuits, etc., can solve problems affecting device leakage current and breakdown voltage, improve crystal quality, reduce density, and alleviate lattice mismatch Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

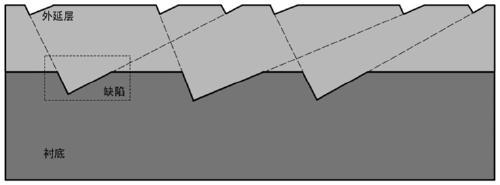

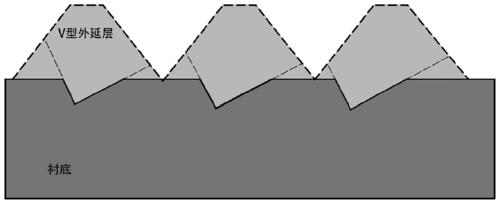

Problems solved by technology

Method used

Image

Examples

Embodiment 1

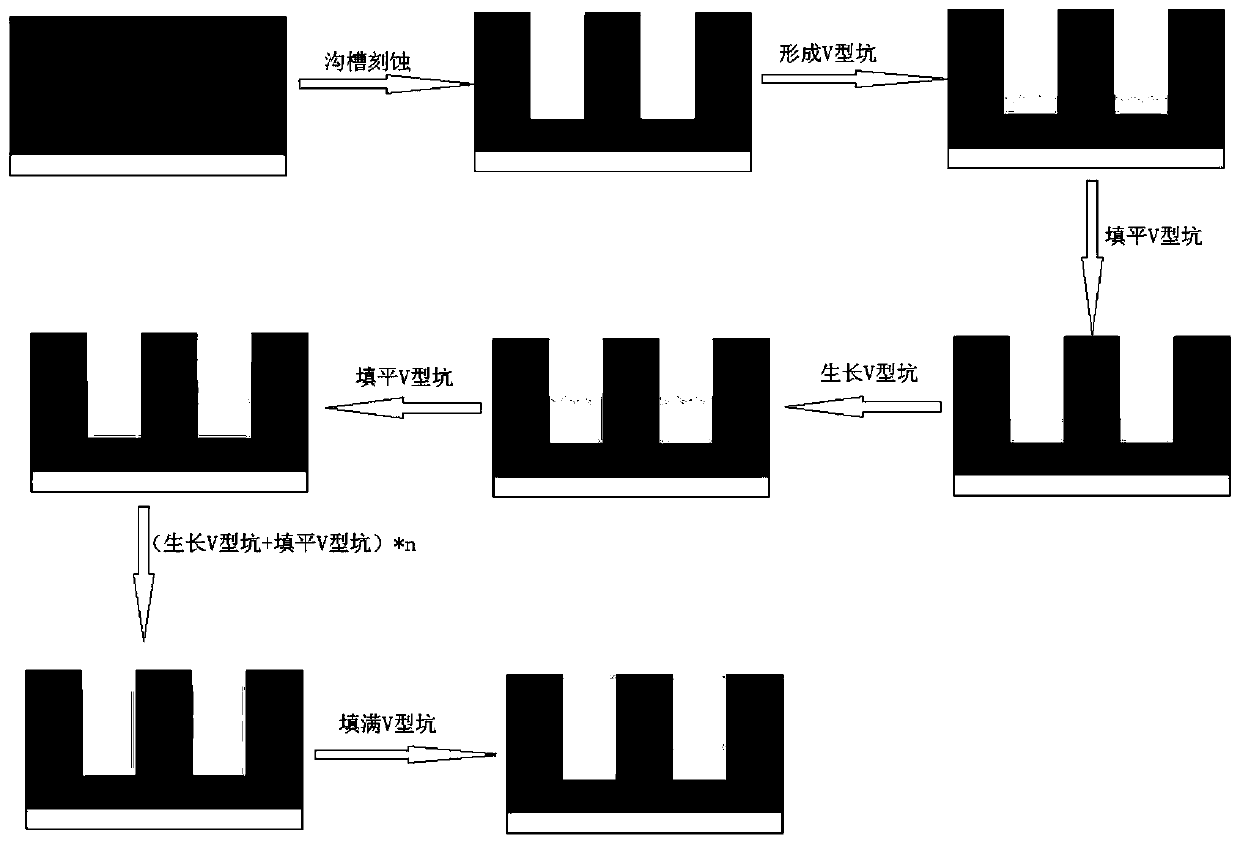

[0038] A method for filling a SiC epitaxial deep trench, comprising the following steps:

[0039] (1) 40-50 μm grown in epitaxial furnace, doping concentration 3×10 14 cm -3 ~9×10 16 cm -3N-type 4H-SiC epitaxial layer, take it out and clean it; groove etch the N-type 4H-SiC epitaxial layer grown on the substrate, the etching depth is greater than 10 μm along the crystal direction, and the groove side wall inclination angle 90°, the width of the bottom is consistent with the width of the top of the mesa, both are 1.5-2 μm, the mask is removed after etching; it is cleaned again, dried, and sent to the epitaxial furnace;

[0040] (2) Partially fill the etched trenches, and feed chlorine-containing silicon source gas, carbon source, HCl and Al doping at flow rates of 100-200 sccm, 100-200 sccm, 1000-5000 sccm and 20-50 sccm respectively agent, while passing H 2 and an inert gas such as helium or argon as a carrier gas, H 2 / The inert gas is 1~1 / 3, the total amount of carri...

Embodiment 2

[0046] A method for filling SiC epitaxial deep trenches, the others are the same as in Embodiment 1, except that between steps (1) and (2), a step of filling the intrinsic 4H-SiC buffer layer into the etched trenches is also included, The specific method is: close the N 2 For the dopant, an intrinsic SiC epitaxial layer with a thickness of 10-100 nm is grown as a buffer layer under the conditions for growing an N-type epitaxial layer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com