Preparation method of lithium-sulfur battery diaphragm barrier layer based on two-dimensional nano-clay

A lithium-sulfur battery, two-dimensional nanotechnology, which is applied in the field of preparation of a lithium-sulfur battery separator barrier, can solve the problems of weakening the overall energy density of the battery, the thickness and mass of the barrier layer, etc., and achieves excellent cation exchange properties, a simple method, The effect of excellent electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

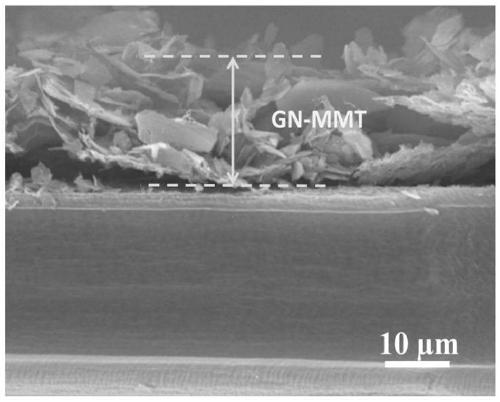

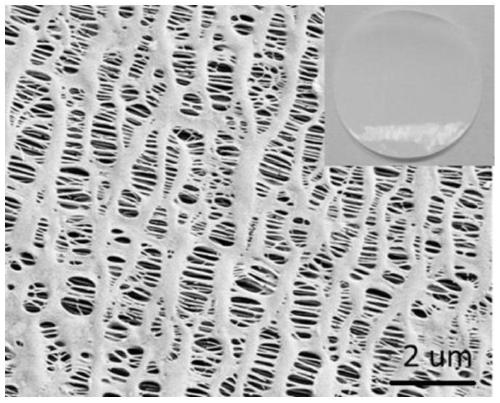

[0043] A preparation method of a lithium-sulfur battery diaphragm barrier layer based on two-dimensional nanoclay, specifically comprising the following steps:

[0044] (1) Add 6g of montmorillonite powder and 18.9g of anhydrous lithium chloride to 450ml of deionized water, stir and heat in an oil bath at 80°C for 12-48h, dialyze, centrifuge, and freeze-dry the supernatant to obtain montmorillonite aerosol glue.

[0045] (2) Dissolve 500 mg of montmorillonite airgel in 500 mL of deionized water to obtain a 1 mg / mL montmorillonite dispersion.

[0046] (3) Take 500 mg of graphene oxide powder prepared by the improved Hummers method and add it into 500 mL of water for 1 h to obtain a 1 mg / mL graphene oxide dispersion.

[0047] (4) Mix the montmorillonite dispersion obtained in step (2) with the graphene oxide dispersion obtained in step (3) in a certain ratio, so that the ratio of graphene oxide to montmorillonite is 1:1-10:1 mixed dispersion.

[0048] (5) Freeze-drying the mi...

Embodiment 2

[0053] A preparation method of a lithium-sulfur battery diaphragm barrier layer based on two-dimensional nanoclay, specifically comprising the following steps:

[0054] (1) Add 4g of montmorillonite powder and 10g of anhydrous lithium chloride to 450ml of deionized water, stir and heat in an oil bath at 70°C for 12-48h, dialyze, centrifuge, and freeze-dry the supernatant to obtain montmorillonite airgel .

[0055] (2) Dissolve 500 mg of freeze-dried montmorillonite powder in 500 ml of deionized water to obtain a 1 mg / mL montmorillonite dispersion.

[0056] (3) Take 500 mg of graphene oxide powder prepared by the improved Hummers method and add it into 500 mL of water for 1 h to obtain a 1 mg / mL graphene oxide dispersion.

[0057] (4) Mix the montmorillonite dispersion obtained in step (2) with the graphene oxide dispersion obtained in step (3) in a certain ratio, so that the ratio of graphene oxide to montmorillonite is 1:1-10:1 mixed dispersion.

[0058] (5) Freeze-drying ...

Embodiment 3

[0063] A preparation method of a lithium-sulfur battery diaphragm barrier layer based on two-dimensional nanoclay, specifically comprising the following steps:

[0064] (1) Add 6g of montmorillonite powder and 80g of anhydrous lithium chloride to 450ml of deionized water, stir and heat in an oil bath at 100°C for 12-48h, dialyze, centrifuge, and freeze-dry the supernatant to obtain montmorillonite airgel .

[0065] (2) Dissolve 500 mg of freeze-dried montmorillonite powder in 500 ml of deionized water to obtain a 1 mg / mL montmorillonite dispersion.

[0066] (3) Take 500 mg of graphene oxide powder prepared by the improved Hummers method and add it into 500 mL of water for 1 h to obtain a 1 mg / mL graphene oxide dispersion.

[0067] (4) Mix the montmorillonite dispersion obtained in step (2) with the graphene oxide dispersion obtained in step (3) in a certain ratio, so that the ratio of graphene oxide to montmorillonite is 1:1-10:1 mixed dispersion.

[0068] (5) Freeze-drying...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com