Spraying building type gypsum three-layer heat-preservation composite double-layer external wall body and preparation body thereof

A technology of three-layer insulation and composite double-layer, which is applied in insulation, walls, buildings, etc., to avoid thermal bridges and improve energy-saving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

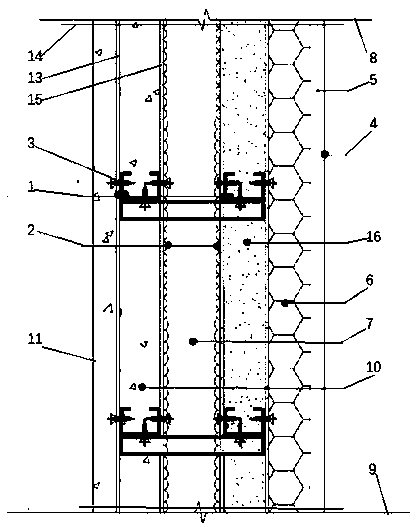

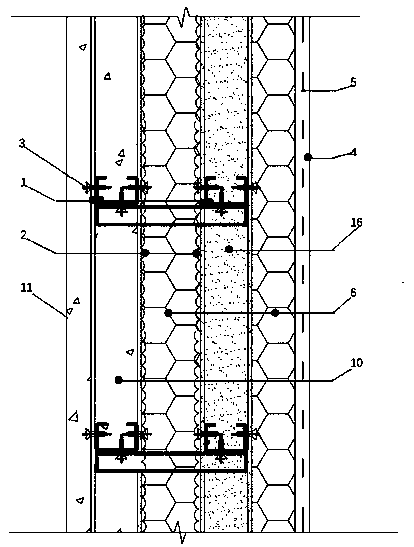

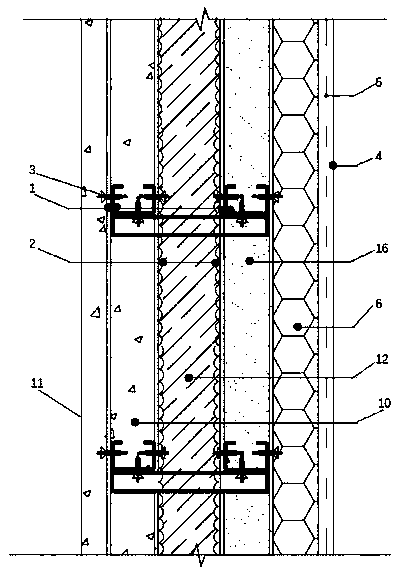

[0041] The following examples respectively describe a spray-built gypsum three-layer thermal insulation composite double-layer exterior wall body and its construction method according to the present invention. See attached figure 1 , the said wall in this example is composed of wall upper end beam 8, wall lower end beam 9, double-layer light steel keel skeleton 1, steel wire mesh 2, anchor bolt 3, wall outer layer 4, wall inner layer 11, Mesh cloth layer 5, cement mortar layer 16, insulation board layer 6, wall center filling layer 7, gypsum mortar layer 10, wherein, the double-layer light steel keel skeleton 1 is arranged on the cement mortar layer 16 and Between the gypsum mortar layers 10, the steel wire mesh 2 is fixed on the double-layer light steel keel frame 1 by the anchor bolt 3, and the two ends of the steel wire mesh 2 extend up and down to the upper end beam 8 of the wall body and the lower end beam 9 of the wall body respectively. and fixed by bolts 3; the wall c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com