Online automatic sampling method and device for machine-made sand production monitoring system

A technology of automatic sampling and monitoring system, applied in sampling device, sampling, measuring device, etc., can solve the problems of low degree of automation and cumbersome sampling, and achieve the effect of high degree of automation, simple sampling procedure and reasonable structure design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

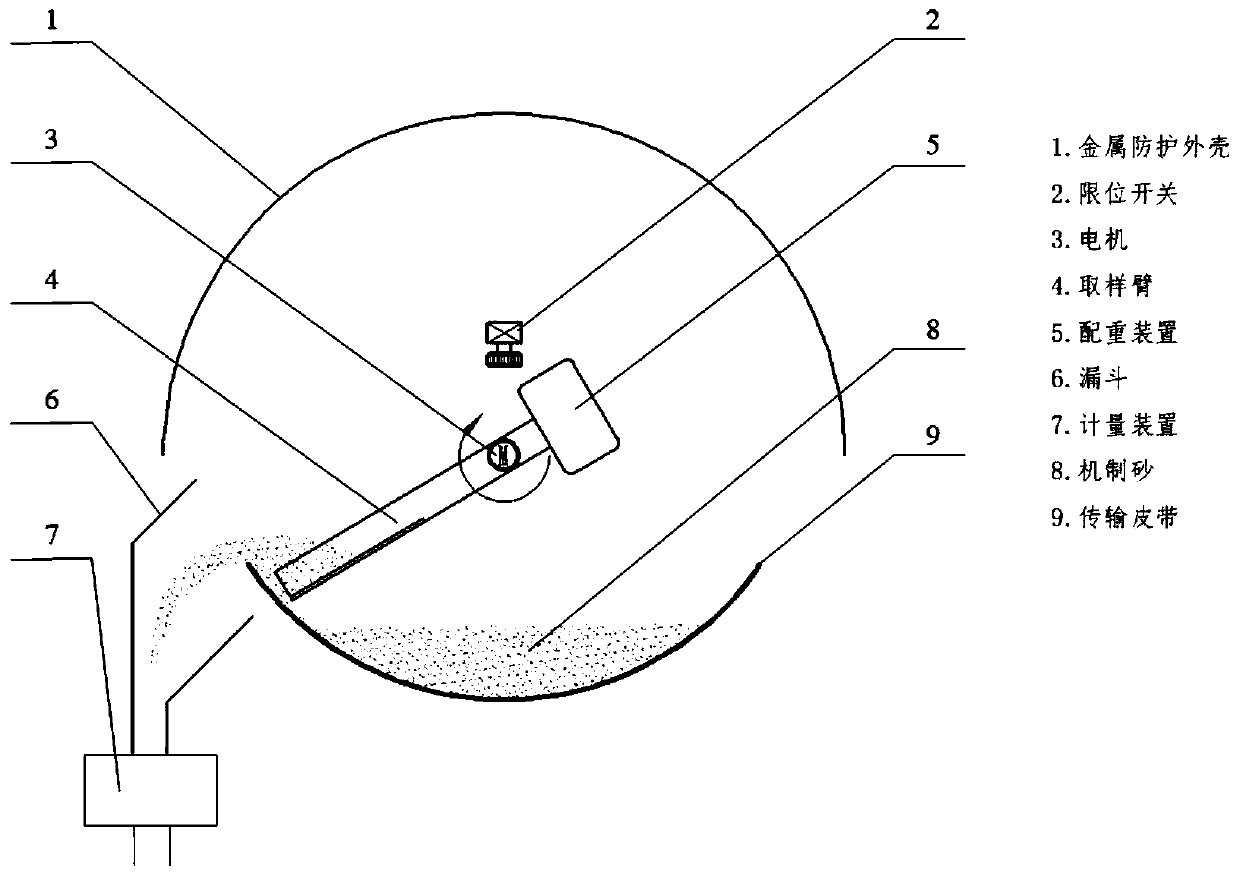

[0015] The technical solution of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings.

[0016] Actually inspect the installation environment of the sampling device, determine the diameter of the circular motion of the sampling arm, and install the sampling arm (4), counterweight device (5), motor (3), and limit switch (2) in the metal protective casing (1) Then fix the metal casing (1), funnel (6) and metering device (7) above the conveyor belt of the machine-made sand production line in order to connect the circuits between the modules. The system processing software sends a sampling command, and the motor (3) drives the sampling arm (4) to perform circular motion. During the circular motion, the sampling arm (4) scrapes the machine-made sand on the transmission belt into the funnel 6 through the rectangular chute at the front end, and samples The arm (4) continues to move in a circular m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com