Method for manufacturing antimicrobial plastic masterbatch using macsumsuk granules

An antibacterial plastic and amphibole powder technology, which is applied in the field of preparing the antibacterial plastic masterbatch of amphibole granules, can solve the problems of decreased antibacterial ability, inability to provide uniform quality, etc., and achieve the effect of preventing the decline of physical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0099] Preparation of wheat amphibole slurry

[0100] After putting the raw material of amphibole crushed into 0.1-5mm into the furnace, adjust the temperature and pressure to make the temperature reach 1200°C.

[0101] For the first ignition, the pressure was adjusted to 0.1 kg / hour using liquefied petroleum gas (LPG) (hereinafter referred to as "gas") in the furnace, and the temperature was brought to 300° C. within 1 hour.

[0102] After 1 hour, the gas pressure was adjusted to 0.125 kg / hr to bring the temperature to 500°C in 1 hour.

[0103] If it reaches 500°C, adjust the gas pressure to 0.15 kg / hour to bring the temperature to 700°C within 1 hour.

[0104] If the temperature in the furnace reaches 700°C, adjust the gas pressure to 0.2 kg / hour to bring the temperature to 850°C within 1 hour.

[0105] When it reaches 850° C., the gas pressure is fixed at 0.2 kg / hour and kept for about 1 hour to completely burn the organic substances contained in the raw material.

[010...

Embodiment 2

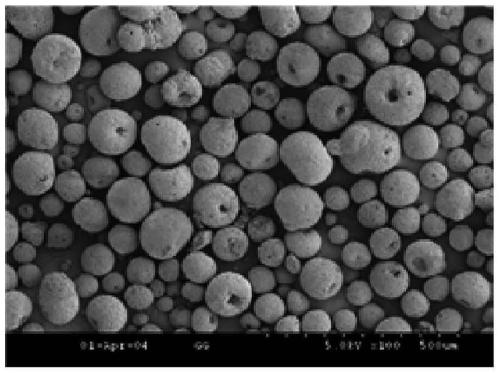

[0114] Preparation of wheat amphibole granules

[0115] In order to improve the porosity of the final particles, a 1:1 weight ratio mixture of calcium carbonate and sodium carbonate was added to the slurry prepared in Example 1 as a foaming agent, with respect to the solid content of the above-mentioned slurry of 100 parts by weight , adding 5 parts by weight, and adding 1 part by weight of silver nanoparticles as an antibacterial substance to prepare a granulated mixture.

[0116] Then, for granulation, ignite the furnace of the hot air stove by spray drying method and raise the temperature within 2 hours to make the internal temperature reach 1000°C, if it reaches 1000°C, start the blower to move the heat to the inside of the cyclone, 300 ℃, then put the nozzle into the lower end of the cyclone, with 40kgf / cm 2 The pump pressure will float the finely divided granulated mixture at the upper point of the inflow weight.

[0117] The radiated liquid phase falls down by vortex ...

Embodiment 3

[0121] Preparation of masterbatch

[0122] A low-density polyethylene was prepared as a plastic raw material, and the above-mentioned amphibole particles were made into 30% by weight, mixed with 70% by weight of low-density polyethylene, and then put into a melt extruder.

[0123] Set the temperature inside the furnace of the melting extruder at 180-350°C. While realizing the melting of the plastic raw material, disperse the amphibole particles evenly in the plastic raw material and extrude it. After cooling the extruded product, it is prepared by cutting. masterbatch.

[0124] Figure 6 The left side of the figure shows the low-density polyethylene plastic raw material, the middle shows the wheat amphibole particles, and the right side shows the masterbatch.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com