Preparation process of fermented mellow type tea cigarettes

A preparation process and technology for tea cigarettes, applied in the directions of tobacco, tobacco treatment, application, etc., can solve the problems of smokers' discomfort, bitterness, poor substitution effect, etc., reduce green gas and bitter taste, improve mellow taste, and improve palatability. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

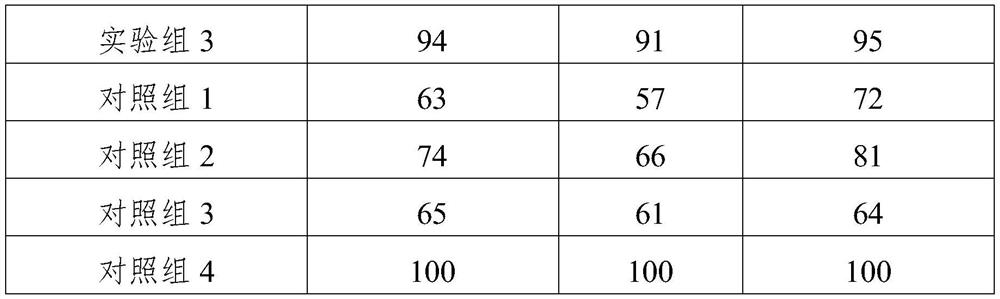

Examples

Embodiment 1

[0028] A preparation process for fermented mellow-flavored tea tobacco, said preparation process for fermented mellow-flavored tea tobacco comprises the following steps:

[0029] (1) Greening of fresh tea leaves: pick fresh green tea, rinse with water, drain the water, cut into shredded tea, and then dry it with hot air at 70°C until the surface changes color, then get shredded tea for later use, and the water content of shredded tea after drying ≦20%;

[0030] (2) Tea shredded blanching: Mix 1 part of coffee beans, 4 parts of Tibetan green fruit, 1 part of tangerine peel, and 25 parts of clear water in the following parts by weight to obtain a blanching solution after boiling for 20-30 minutes. After blanching in hot liquid for 40 seconds, take it out, let it cool, and get the blanched tea shreds for later use;

[0031] (3) Primary fermentation: after the above-mentioned blanched shredded tea is added to honey and stirred evenly, then the compound fermenting bacteria A is ad...

Embodiment 2

[0038] A preparation process for fermented mellow-flavored tea tobacco, said preparation process for fermented mellow-flavored tea tobacco comprises the following steps:

[0039] (1) Greening of fresh tea leaves: Pick fresh green tea, rinse with water, drain the water and cut into shredded tea, then dry it with hot air at 75°C until the surface changes color, and then get the shredded tea for later use, and the water content of the shredded tea after drying ≦20%;

[0040] (2) Tea shreds blanching: mix the following parts by weight of 2 parts of coffee beans, 6 parts of Tibetan green fruit, 3 parts of dried tangerine peel, and 30 parts of clear water and boil for 30 minutes to obtain a blanching solution. Put the above-mentioned shredded tea into the boiling blanching liquid After medium blanching for 50s, take it out, let it cool, and get the blanched tea shreds for later use;

[0041] (3) Primary fermentation: after the above-mentioned blanched shredded tea was added to hone...

Embodiment 3

[0048] A preparation process for fermented mellow-flavored tea tobacco, said preparation process for fermented mellow-flavored tea tobacco comprises the following steps:

[0049] (1) Greening of fresh tea leaves: pick fresh green tea, rinse with water, drain the water, cut into shredded tea, and then dry it with hot air at 73°C until the surface changes color, then get shredded tea for later use, and the water content of shredded tea after drying ≦20%;

[0050] (2) Tea shreds blanching: Mix 1.5 parts of coffee beans, 5 parts of Tibetan green fruit, 2 parts of tangerine peel, and 28 parts of clear water in the following parts by weight to obtain a blanching solution after boiling for 25 minutes. Put the above-mentioned shredded tea into the boiling blanching liquid After medium blanching for 45s, take it out, let it cool, and get the blanched tea shreds for later use;

[0051] (3) Primary fermentation: after the above-mentioned blanched shredded tea is added to honey and stirr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com