Nail essence

A technology of essence and nails, which is applied in the field of cosmetic products, can solve problems such as strong odor, consumer concerns, and general effect of nail essence products, and achieve the effect of maintaining stability and enhancing rapid absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

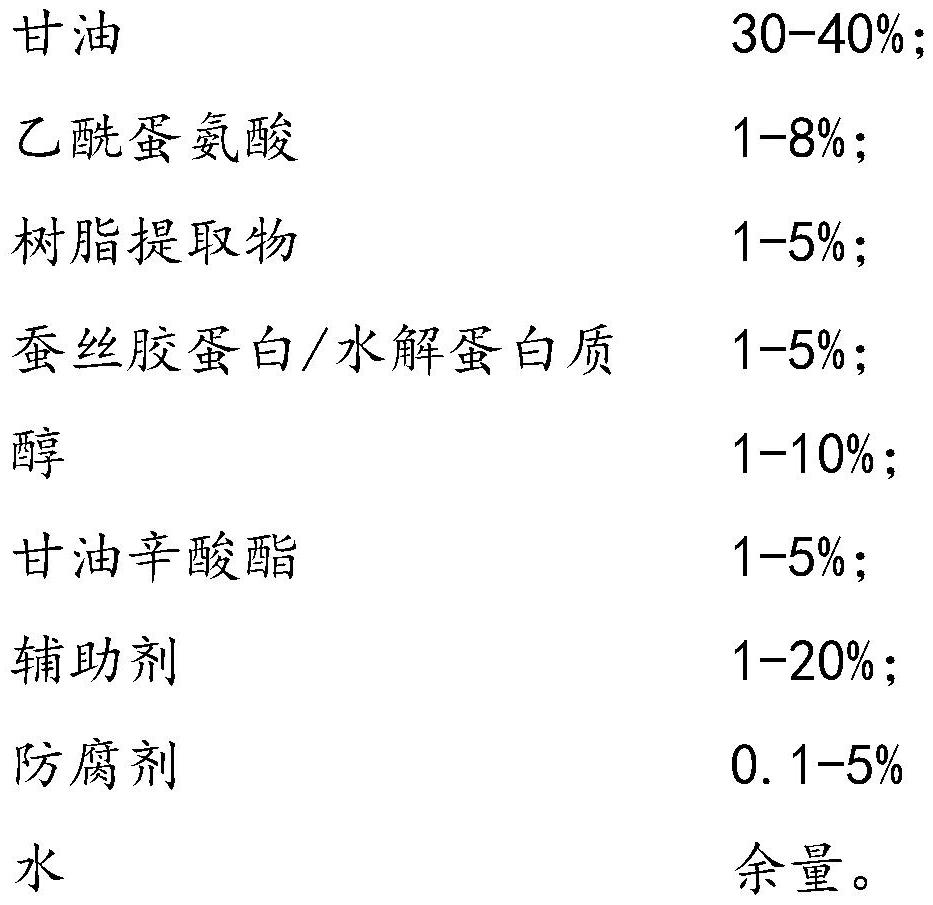

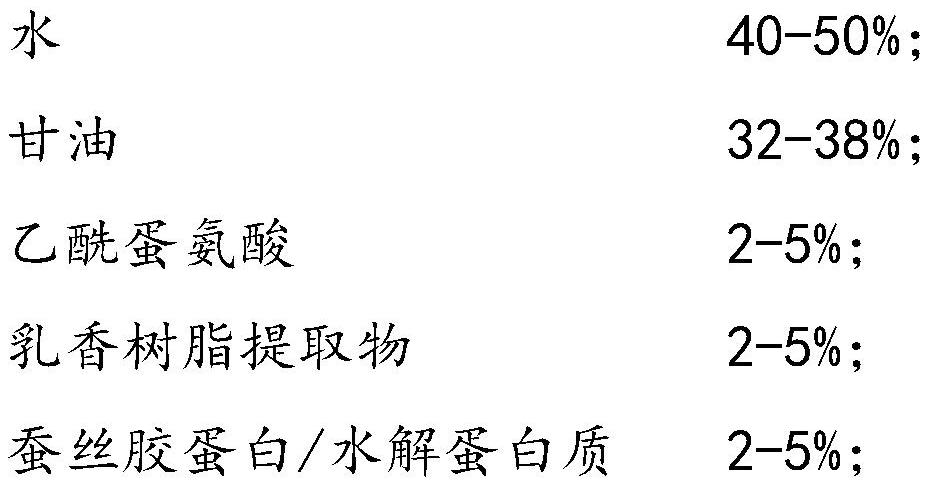

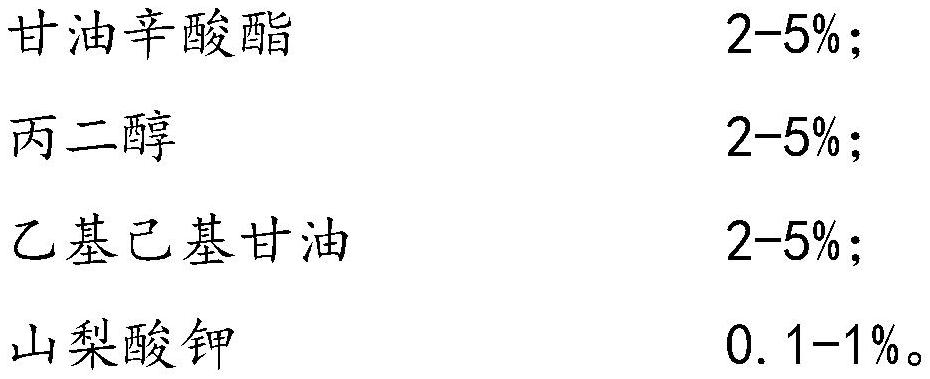

Method used

Image

Examples

Embodiment 1

[0027] Ingredients: 46% of water used in the product, 36.5% of glycerin, 4% of acetylmethionine, 3% of frankincense resin extract, 3% of silk gum protein, 2.5% of glycerin caprylate, 2.5% of propylene glycol, and 2% of ethylhexylglycerin , Potassium sorbate 0.5%.

[0028] Process flow:

[0029] Step 1: Prepare component A

[0030] Mix 10 parts of water + 6.5 parts of glycerin + 4 parts of acetylmethionine, stir at 100-200 rpm, heat to 45°C, keep stirring at this temperature for 30-45 minutes, cool to room temperature for use, the In the step, the acetylmethionine is fully dissolved in the water and glycerin system in advance.

[0031] Step 2: Prepare Component B

[0032] 31 parts of water + 25 parts of glycerin + 3 parts of frankincense resin extract + 3 parts of silk gum protein + 2.5 parts of glycerin caprylate + 2.5 parts of propylene glycol + 2 parts of ethylhexyl glycerin for mixing, stirring at a speed of 100-200 rpm , and heated to 45° C., kept stirring at this temp...

Embodiment 2

[0036] Ingredients: 43% of water used in the product, 34.4% of glycerin, 5% of ethanol, 4% of acetylmethionine, 3% of frankincense resin extract, 3% of silk gum protein, 2.5% of glycerin caprylate, 2.5% of propylene glycol, ethyl alcohol Hexylglycerin 2%, potassium sorbate 0.5%, CI12490, 0.1%.

[0037] Process flow:

[0038] Step 1: Prepare component A

[0039] Mix 10 parts of water + 6.4 parts of glycerin + 4 parts of acetylmethionine, stir at 100-200 rpm, heat to 45°C, keep stirring at this temperature for 30-45 minutes, cool to room temperature for use.

[0040] Step 2: Prepare Component B

[0041] 28 parts of water + 23 parts of glycerin + 5 parts of ethanol + 3 parts of boswellia resin extract + 3 parts of silk gum protein + 2.5 parts of glycerin caprylate + 2.5 parts of propylene glycol + 2 parts of ethylhexyl glycerin are mixed at 100- Stir at 200 rpm, heat to 45°C, keep stirring at this temperature for 45-60 minutes, and cool to room temperature for use.

[0042] S...

Embodiment 3

[0045] Composition: Glycerin 40%, ethanol 5%, acetylmethionine 1%, frankincense resin extract 5%, hydrolyzed protein (protein hydrolyzate) 5%, glyceryl caprylate 1%, propylene glycol 2%, ethyl alcohol used in the product Hexylglycerin 2%, Potassium Sorbate 0.1%, Colorant 0.2%, Water balance.

[0046] Process flow:

[0047] Step 1: Prepare component A

[0048] Mix 10 parts of water + 5 parts of glycerin + acetylmethionine, stir at 100-200 rpm, heat to 45°C, keep stirring at this temperature for 30-45 minutes, cool to room temperature for use.

[0049] Step 2: Prepare Component B

[0050] 20 parts of water + 23 parts of glycerin + ethanol + frankincense resin extract + sericin + caprylic acid ester + propylene glycol + ethylhexylglycerin are mixed, stirred at a speed of 100-200 rpm, and heated to 45 ° C, Stirring was continued at this temperature for 45-60 minutes, and cooled to room temperature for use.

[0051] Step 3: Mix component A + component B + remaining water + rema...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com