Polythiophene derivative conductive film based on in-situ doping modification, and preparation method and application of polythiophene derivative conductive film

A technology of polythiophene derivatives and in-situ doping, which is applied in the field of organic photoelectric materials, can solve the problems of low conductivity and limitations, and achieve the effects of improving conductivity, avoiding residues of impurities, and avoiding uncontrollable structural composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The invention discloses a method for preparing a polythiophene derivative conductive film based on in-situ doping, which comprises the following steps:

[0038] ①Use deionized water, acetone and alcohol to ultrasonically clean the insulating glass sheet (1.5cm×1.5cm) several times, then let it dry for later use;

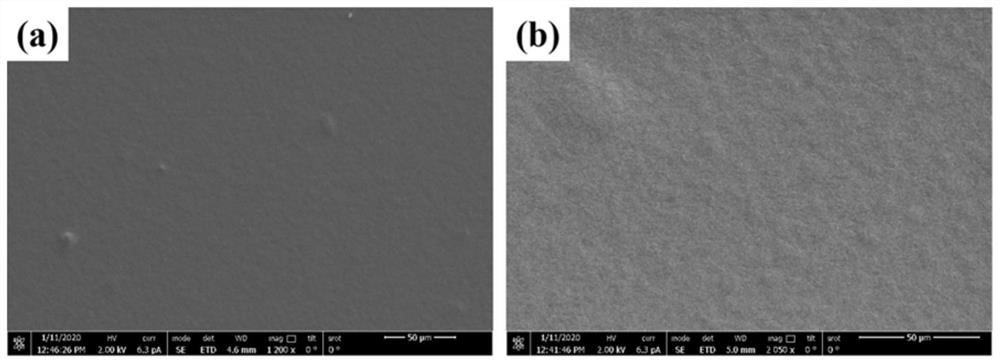

[0039] ②In the process of preparing the initial film, weigh 30 mg of PBTTT (poly(2,5-bis(3-tetradecylthiophen-2-yl)thieno[3,2-b]thiophene) with an electronic balance, and then Dissolve it in 1ml of 1,2-dichlorobenzene (DCB) to obtain a uniform solution, drop-coat the resulting solution on the prepared glass sheet, and then bake it at 70°C for 12 hours to prepare the initial PBTTT film;

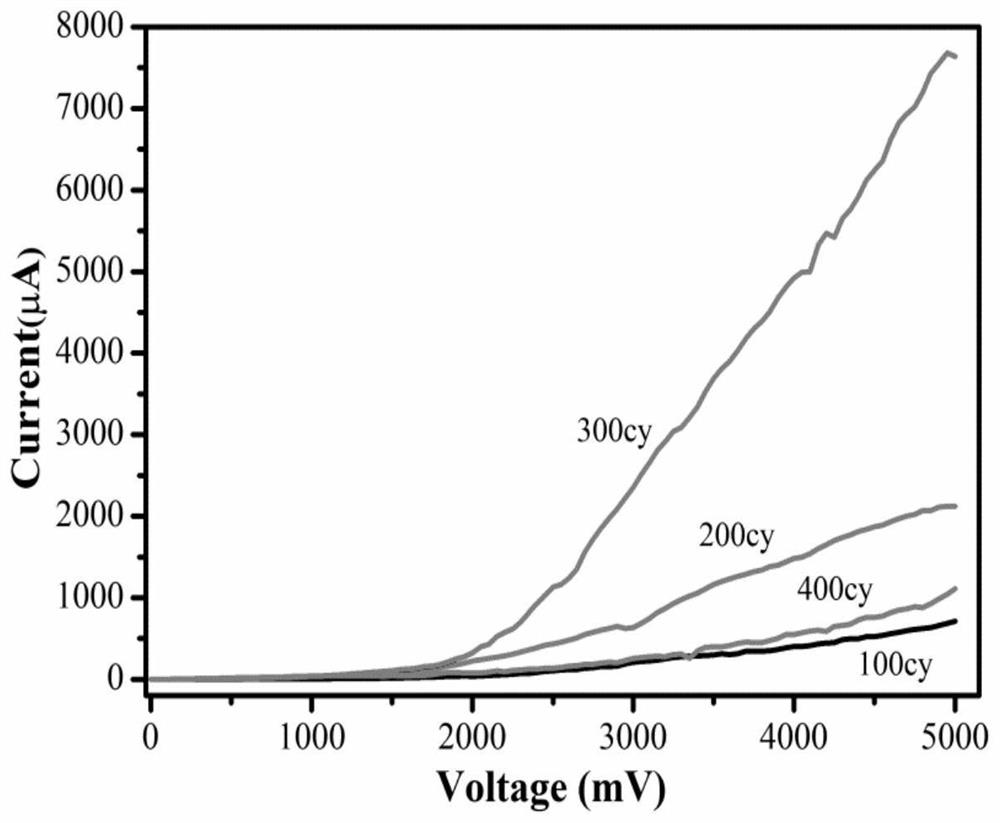

[0040] ③ Finally, put the prepared PBTTT initial film into the reaction chamber of the ALD equipment, and use MoCl 5 Perform gas phase infiltration cycle to achieve in-situ doping modification, one infiltration cycle includes (precursor MoCl 5 Pulse 5s into the reaction cham...

Embodiment 2

[0044] The invention discloses a method for preparing a polythiophene derivative conductive film based on in-situ doping, which comprises the following steps:

[0045] ①Use deionized water, acetone and alcohol to ultrasonically clean the insulating glass sheet (1.5cm×1.5cm) several times, then let it dry for later use;

[0046] ②In the process of preparing the initial film, weigh 30 mg of PBTTT with an electronic balance, and then dissolve it in 1 ml of chloroform (CHCl 3 ) to obtain a uniform solution, drop-coat the resulting solution on the prepared glass sheet, and then bake at 70°C for 12h to prepare the initial PBTTT film;

[0047] ③ Finally, put the prepared PBTTT initial film into the reaction chamber of the ALD equipment, and use MoCl 5 Perform gas phase infiltration cycle to achieve in-situ doping modification, one infiltration cycle includes (precursor MoCl 5 Pulse 5s into the reaction chamber, expose the polymer substrate to the precursor for 120s, and finally use...

Embodiment 3

[0051] The invention discloses a method for preparing a polythiophene derivative conductive film based on in-situ doping, which comprises the following steps:

[0052] ①Use deionized water, acetone and alcohol to ultrasonically clean the insulating glass sheet (1.5cm×1.5cm) several times, then let it dry for later use;

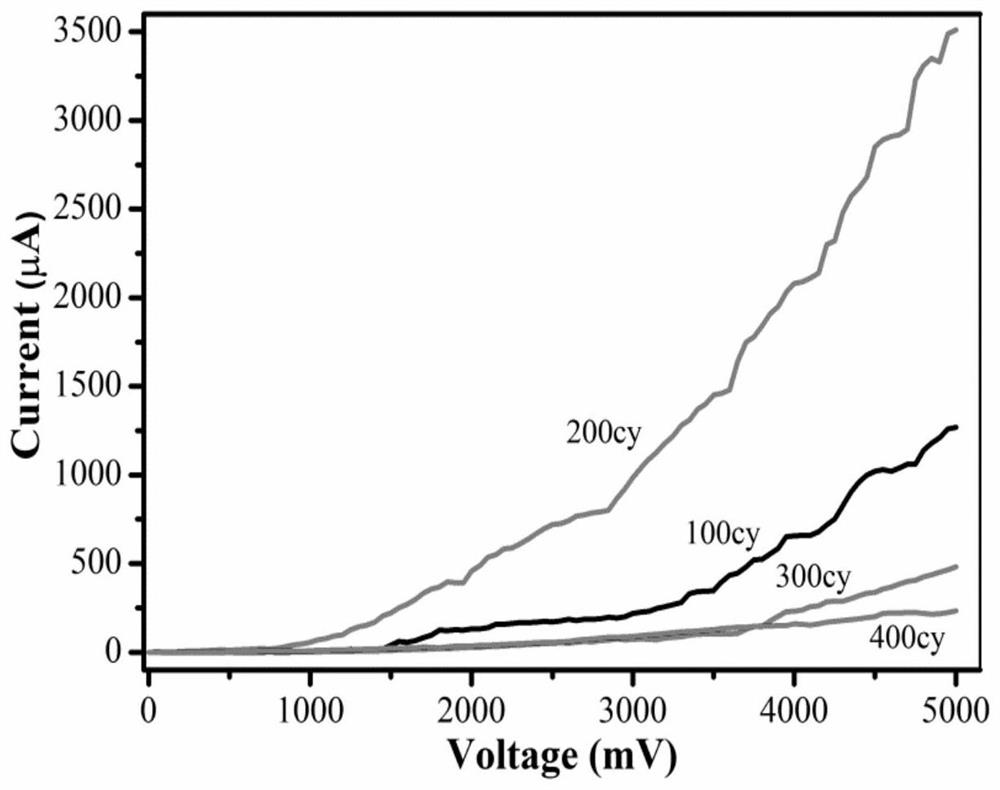

[0053] ②In the process of preparing the initial film, weigh 27mg of PBTTT with an electronic balance, and then dissolve it in 1ml of chloroform (CHCl 3 ) to obtain a uniform solution, drop-coat the resulting solution on the prepared glass sheet, and then bake at 70°C for 12h to prepare the initial PBTTT film;

[0054] ③ Finally, put the prepared PBTTT initial film into the reaction chamber of the ALD equipment, and use MoCl 5 Perform gas phase infiltration cycle to achieve in-situ doping modification, one infiltration cycle includes (precursor MoCl 5 Pulse 3s into the reaction chamber, expose the polymer substrate to the precursor for 90s, and finally use N ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com