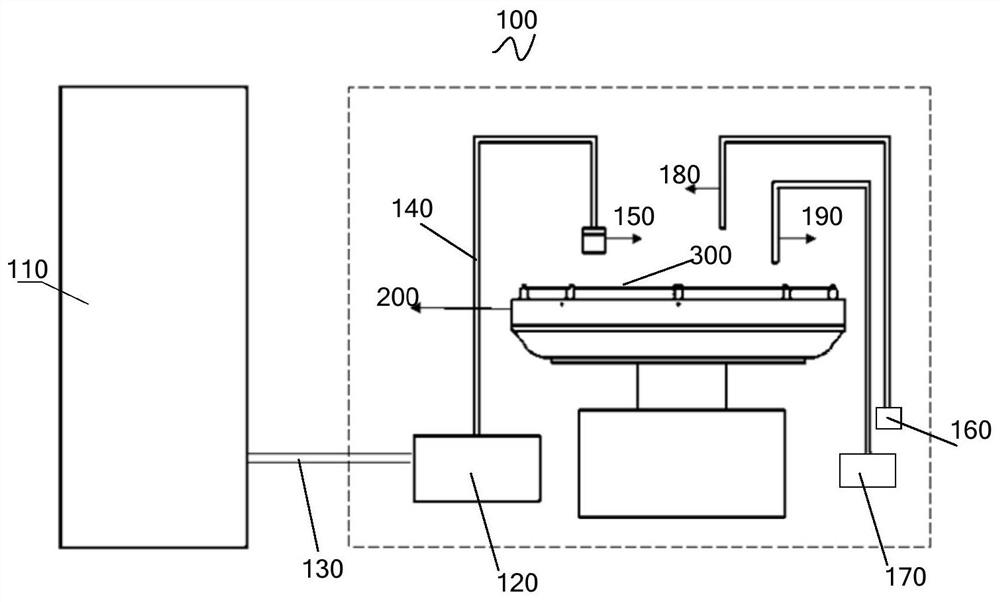

Photoresist removing device and method for removing photoresist

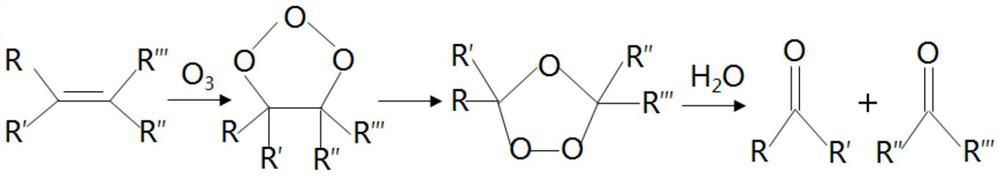

A photoresist and nano-bubble technology, applied in the field of photoresist removal and photoresist removal device, can solve the problems of high cost, high sulfuric acid consumption, device damage, etc., meet the requirements, improve the removal efficiency, and reduce the production cost cheap effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

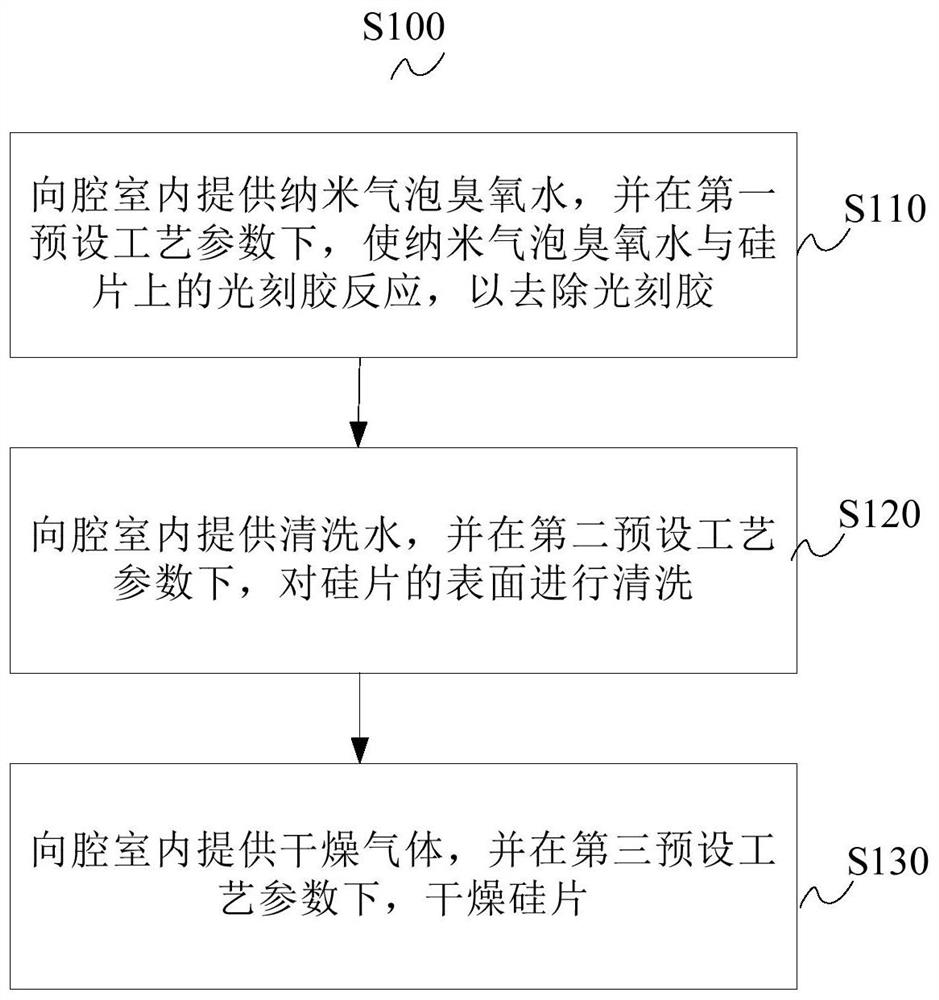

Method used

Image

Examples

Embodiment 1

[0078] In this embodiment, nanobubble ozone water O 3 The concentration of is 20ppm, the vertical distance between the first shower head and the silicon wafer is 15mm, the swing speed of the second end of the nanobubble pipeline is 8rpm, and the remaining process parameters of photoresist cleaning are shown in Table 1:

[0079]

[0080] Table 1 Photoresist cleaning process parameters

Embodiment 2

[0082] In this embodiment, nanobubble ozone water O 3 The concentration is 50ppm, the vertical distance between the first shower head and the silicon wafer is 20mm, the swing speed of the second end of the nanobubble pipeline is 8rpm, and the rest of the photoresist cleaning process parameters are shown in Table 2:

[0083]

[0084] Table 2 Photoresist cleaning process parameters

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com