R-T-B series permanent magnet material, raw material composition and preparation method and application thereof

A technology of R-T-B and raw material composition, applied in the direction of magnetic materials, magnetic objects, inductors/transformers/magnets, etc., can solve the problem of expensive Co

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

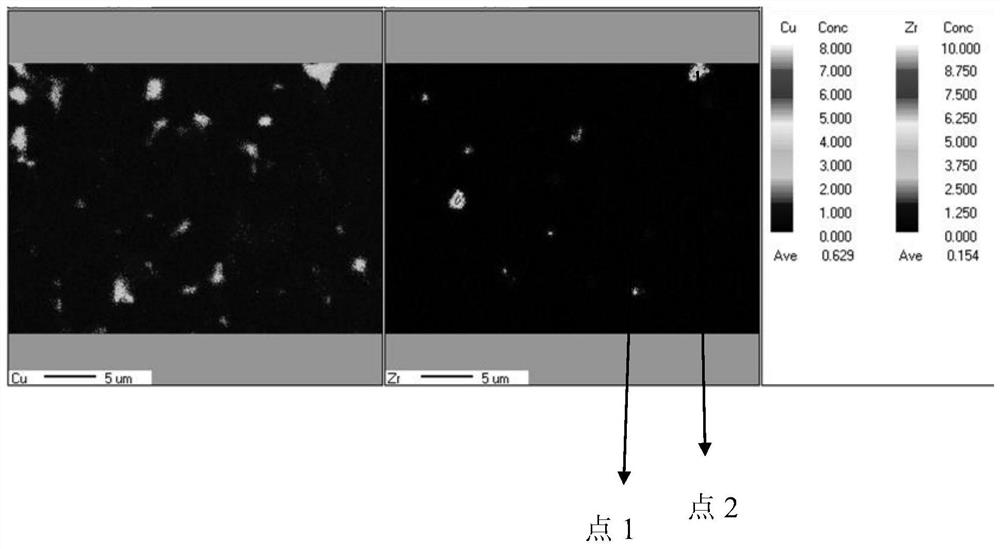

Image

Examples

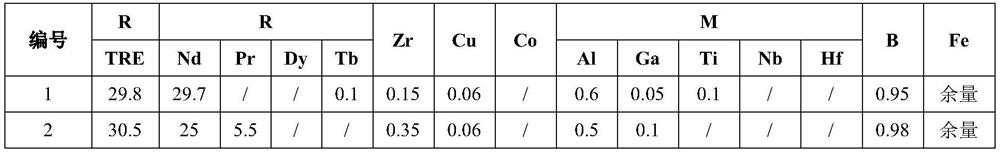

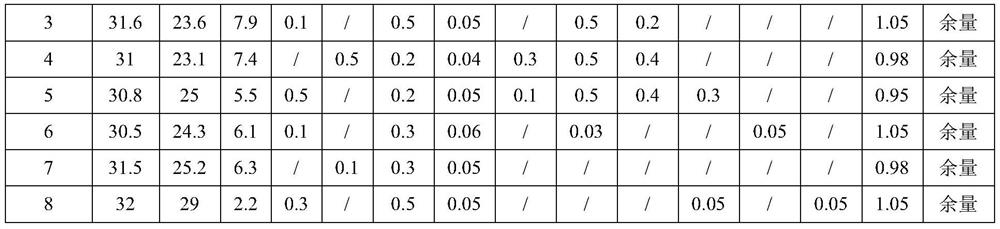

Embodiment 1-8 and comparative example 1-5

[0169] The preparation method of R-T-B series permanent magnet material in embodiment 1-8 and comparative example 1-5 is as follows:

[0170] (1) Melting and casting process: According to the formula in Table 1, the prepared raw materials were put into an alumina crucible, and vacuum melting was carried out in a high-frequency vacuum melting furnace at a vacuum of 0.05 Pa and 1500°C. Argon gas is introduced into the intermediate frequency vacuum induction quick-setting belt furnace for casting, and then the alloy is quenched to obtain alloy sheets.

[0171] (2) Hydrogen crushing process: Vacuumize the hydrogen crushing furnace where the quenched alloy is placed at room temperature, and then pass hydrogen gas with a purity of 99.9% into the hydrogen crushing furnace to maintain the hydrogen pressure at 90kPa. After fully absorbing hydrogen , heat up while vacuuming, fully dehydrogenate, then cool, and take out the powder after hydrogen crushing. Wherein, the temperature of hyd...

Embodiment 9

[0177] The sintered body obtained through sintering treatment in Example 4 was first subjected to grain boundary diffusion treatment, and then to aging treatment. All the other steps are the same as in Example 4. The grain boundary diffusion treatment process is as follows:

[0178] The sintered body is processed into a 20mm×20mm magnet with a sheet thickness of less than 7mm. The thickness direction is the orientation direction of the magnetic field. After the surface is cleaned, the raw materials prepared by Dy fluoride are used to spray and coat the magnet on the whole surface. The final magnet was dried, and then diffusely heat-treated at 850°C for 24 hours in a high-purity Ar atmosphere. Cool to room temperature.

Embodiment 10

[0180] The sintered body obtained through sintering treatment in Example 2 was first subjected to grain boundary diffusion treatment, and then to aging treatment. All the other steps are the same as in Example 2. The grain boundary diffusion treatment process is as follows:

[0181] The sintered body is processed into a 20mm×20mm magnet with a sheet thickness of less than 7mm. The thickness direction is the orientation direction of the magnetic field. After the surface is cleaned, the raw materials prepared by Tb fluoride are used to spray and coat the magnet on the whole surface. The final magnet was dried, and then diffusely heat-treated at 850°C for 24 hours in a high-purity Ar atmosphere. Cool to room temperature.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com