Multi-layer and multi-pass welding device and method based on visual representation

A multi-layer, multi-pass, welding device technology, applied in welding equipment, welding accessories, electrode support devices, etc., can solve the problems of low degree of automation, failure to achieve independent planning and intelligent control, and low efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0087] The detailed content of the present invention and its specific implementation will be further described below in conjunction with the accompanying drawings.

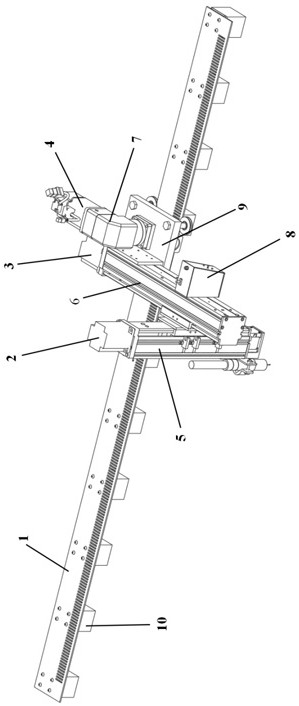

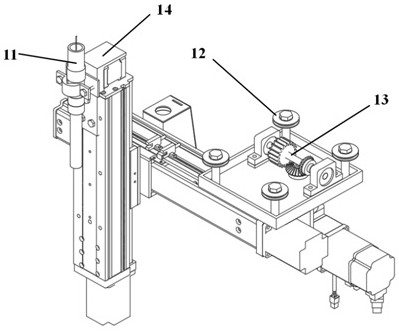

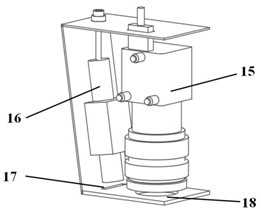

[0088] see Figure 1 to Figure 3 As shown, the multi-layer multi-channel welding device based on visual representation of the present invention includes a walking body, a walking guide rail, a 3D laser profile sensor, and a welding torch. The walking body is installed on the walking guide rail, and the 3D laser profile sensor 8 is installed in the walking body On the y-axis guide rail 6, the welding torch 11 is rigidly fixed on the output shaft of the welding torch pose control servo motor 14 in the walking body; the 3D laser profile sensor scans the weld seam to obtain the welding trajectory and the welding torch pose, and the rear device converts the welding trajectory The signal is converted into a corresponding electrical signal and transmitted to the execution motor of the walking body; the execution motor of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com