A springback deformation suppression method for laser-assisted in-situ formed thermoplastic composite structural parts

A technology of composite materials and in-situ forming, which is applied in the field of composite materials to achieve the effects of improving manufacturing precision, realizing localized adjustment, and improving springback problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

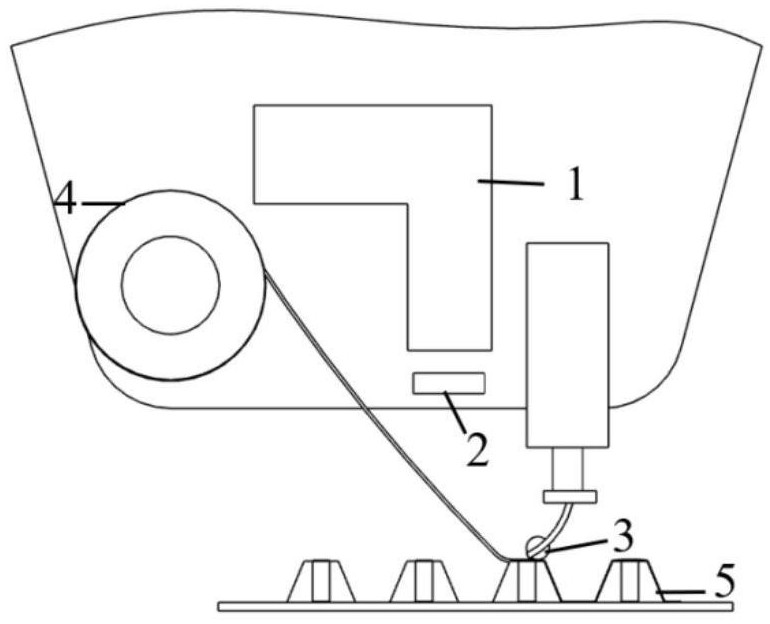

[0027] Step 1: Set the laser power density to 15W / cm by adjusting beam adjuster 2 2 , the spot type is a circular spot laser heat source 1 with a diameter of 15mm, the forming speed is 1000mm / min, the forming temperature is 450°C, and the pressure of the pressing roller 3 is 30N; And heat and pressurize it, so that the prepreg is formed on the surface of the mold 5;

[0028] Step 2: Instead of laying new prepregs, laser and pressure rollers are used to heat and press the prepregs laid in step 1 twice;

[0029] Step 3: Repeat steps 1 and 2 until the sample preparation is completed.

[0030] The prepreg used in step 1 is a carbon fiber reinforced PEEK composite material with a thickness of 0.14mm and a width of 10mm, and a total of 5 layers are laid.

[0031] The second heating and pressing process conditions in step 2 are: the laser power de...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com