Device and process for producing high-activity lime

A production device and high-activity technology, applied in the field of lime production, can solve the problems of high cost of high-activity lime, low lime activity, waste of raw material resources, etc., and achieve the effects of reducing calcination time, saving fuel and reducing fuel energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

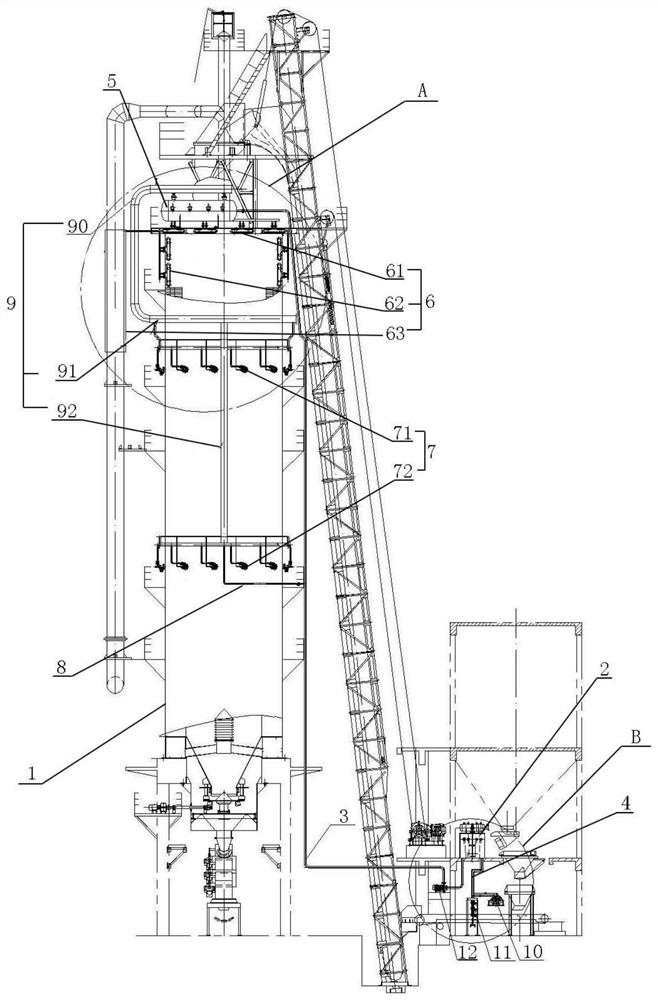

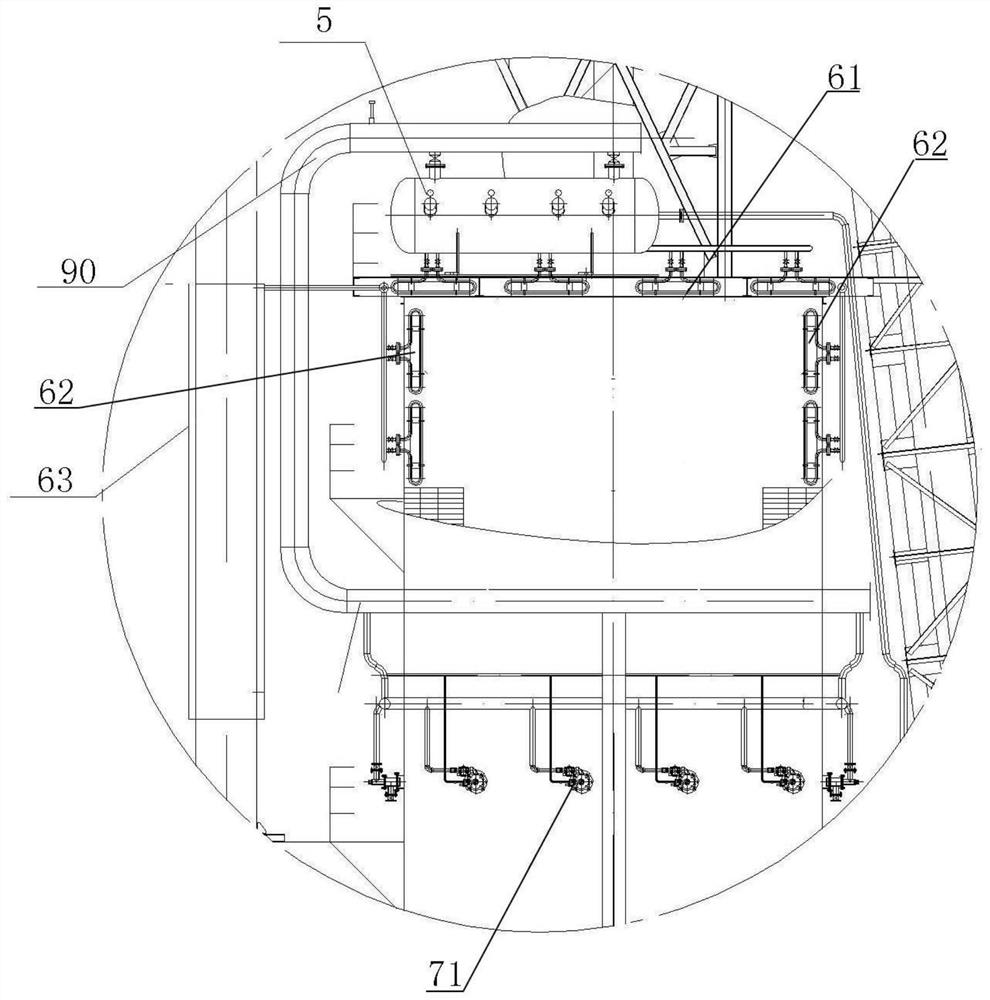

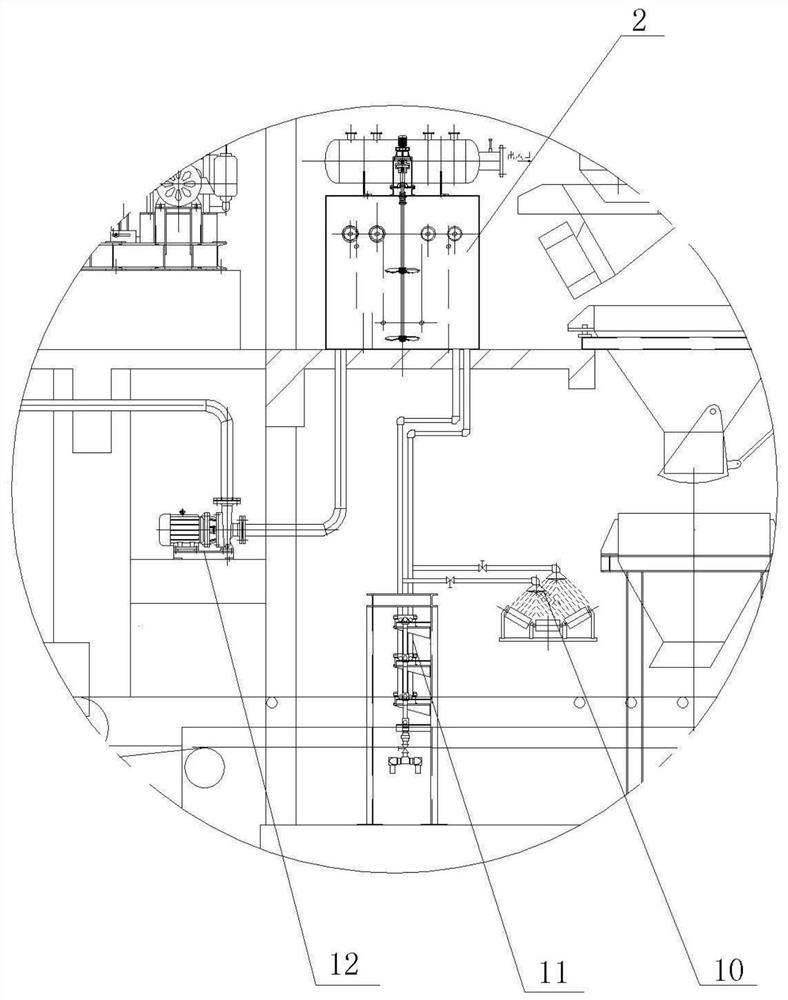

[0033] Such as Figure 1-3A device for producing highly active lime is shown, which includes a vertical kiln 1, a mixed liquid production device 2, a vaporized liquid spraying system and an activation liquid spraying system, and the vaporized liquid spraying system is installed in the shaft kiln 1, the activation liquid spraying system is installed at the stone material feeding place of the shaft kiln 1, the mixed liquid production device is arranged outside the shaft kiln 1, and the mixed liquid production device 2 is sprayed with the vaporized liquid respectively. The blowing system is connected with the activation liquid spraying system. The mixed liquid production device 2 is provided with a vaporized liquid generating device and an activation liquid generating device, the vaporized liquid generating device is connected to the vaporized liquid injection system through a vaporized liquid delivery pipeline 3, and the activated liquid generating device is activated by The li...

Embodiment 2

[0045] A kind of technique of producing highly active lime, described technique utilizes the device described in embodiment 1, and it comprises following steps a:

[0046] Turn on the vaporized liquid generating device in the mixed liquid production device 2 to configure the vaporized liquid, and the configured vaporized liquid is transported by the vaporized liquid delivery pipeline 3 to the steam drum of the vaporized liquid injection system under the action of the vaporized liquid delivery pump 12 5 inside; the vaporized liquid in the steam drum 5 descends through the downpipe to the inside of the first waste heat exchanger 61, the second waste heat exchanger 62 and the third waste heat exchanger 63 to exchange heat with the waste heat of the flue gas, The steam generated after the heat exchange rises to the steam drum 5 through the descending pipe; the steam with a pressure of 0.31-0.36 MPa generated after the separation of the steam-water mixture in the steam drum 5 is tra...

Embodiment 3

[0051] A kind of technique of producing highly active lime, described technique utilizes the device described in embodiment 1, and it comprises following steps b:

[0052] Open the activation solution generating device in the mixed solution production device 2 to configure the activation solution, the mixed activation solution enters the activation solution sprayer 10 of the activation solution spraying system from the activation solution delivery pipeline 4 through the activation solution control valve 11, Spray to the stone material surface on the stone material conveyor belt top through the activation liquid sprinkler 10 again.

[0053] The activation solution is composed of the following raw materials in weight percentage: 25%-30% of mixture B, and the balance is water; the mixture B includes the following raw materials in parts by weight: 45-55 parts of Glauber's salt and 25-35 parts of sodium chloride . The mixture B is cheap, easy to obtain, non-polluting, and has a ve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com