Rapid analysis method of crude biodiesel methanol content

A methanol content, biodiesel technology, applied in the analysis of materials, material analysis through optical means, measurement devices, etc., can solve the problems of affecting the regional atmospheric environment, long detection time, and methanol gas generation, and achieve wide applicability and speed Fast, Versatile Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The rapid analysis method for the methanol content of the crude biodiesel of the present invention will be further described in detail below in conjunction with specific embodiments.

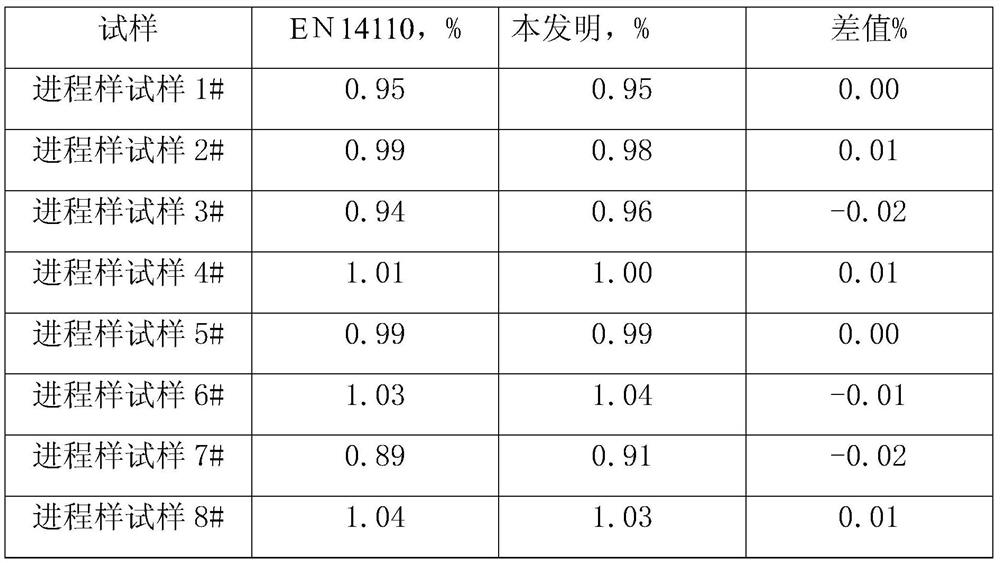

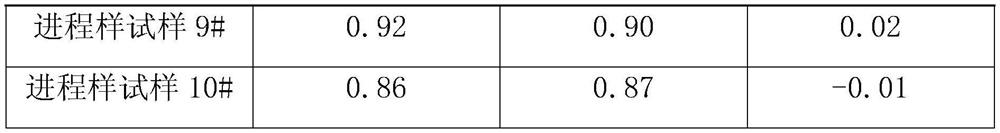

[0021] The rapid analysis method for the methanol content of crude biodiesel in the present invention uses a near-infrared spectrometer as a measuring instrument to measure the methanol content in the production process of fatty acid methyl esters, and utilizes the double frequency and combined frequency absorption of methyl CH and hydroxyl O-H vibrations in oils and fats Generate a spectrogram, make a measurement model with the partial least squares regression and optimal factor number selection principle factor regression method, and indirectly determine the methanol content of the measured sample; the specific production process of the measurement model is: In the model management part of the user manual of Analyzer Measurement and Analysis Software, log in and enter the model managemen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com