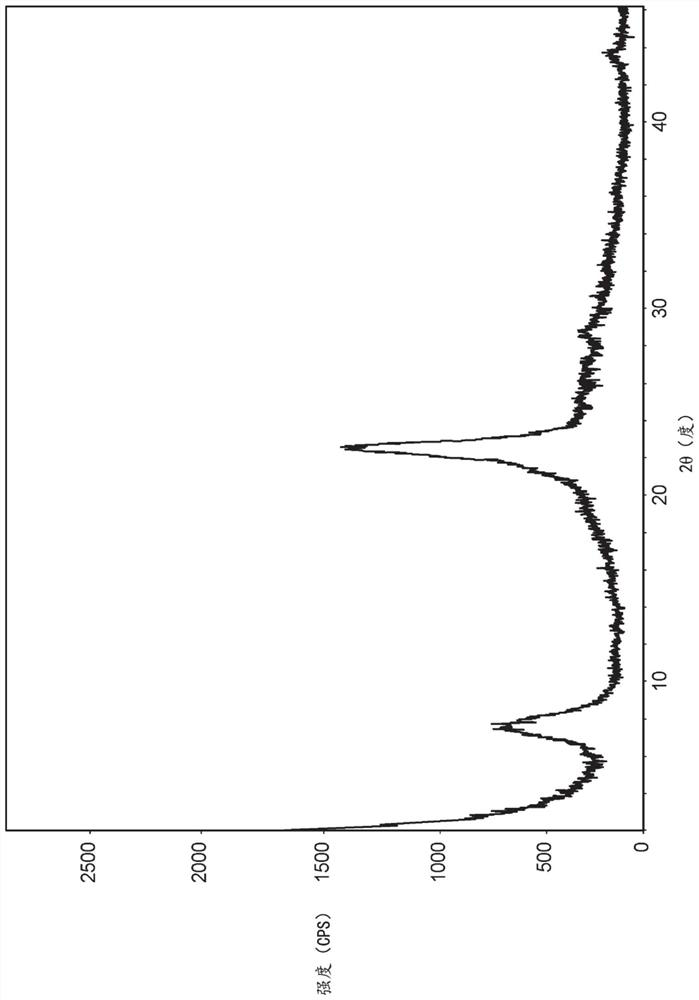

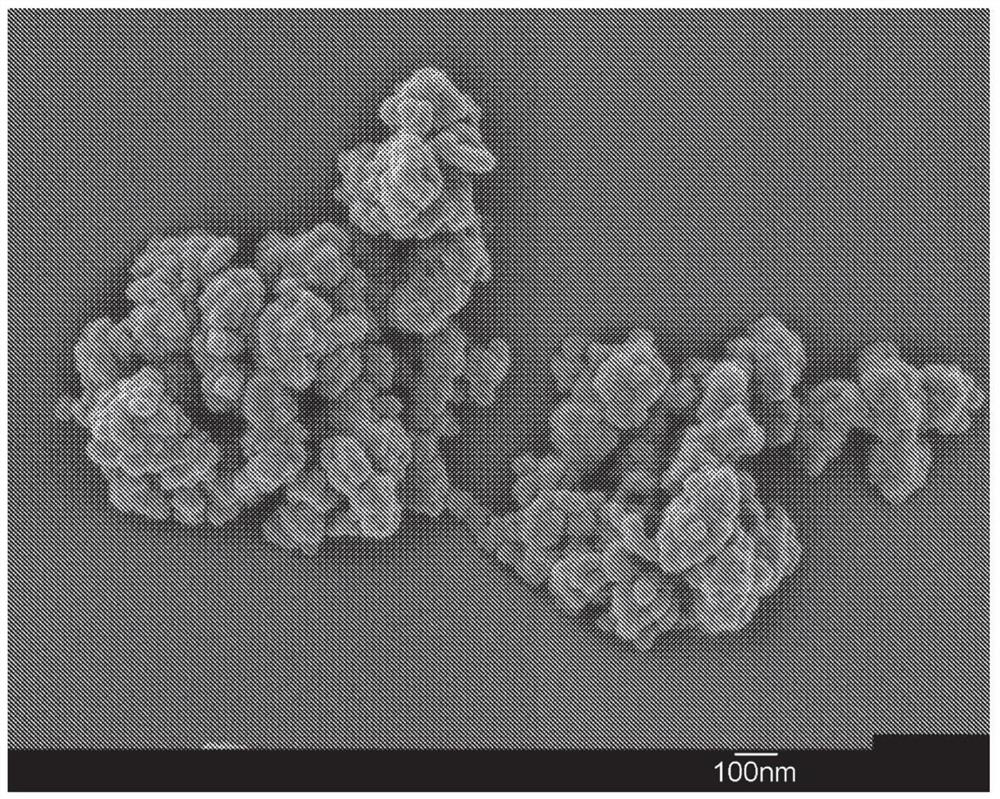

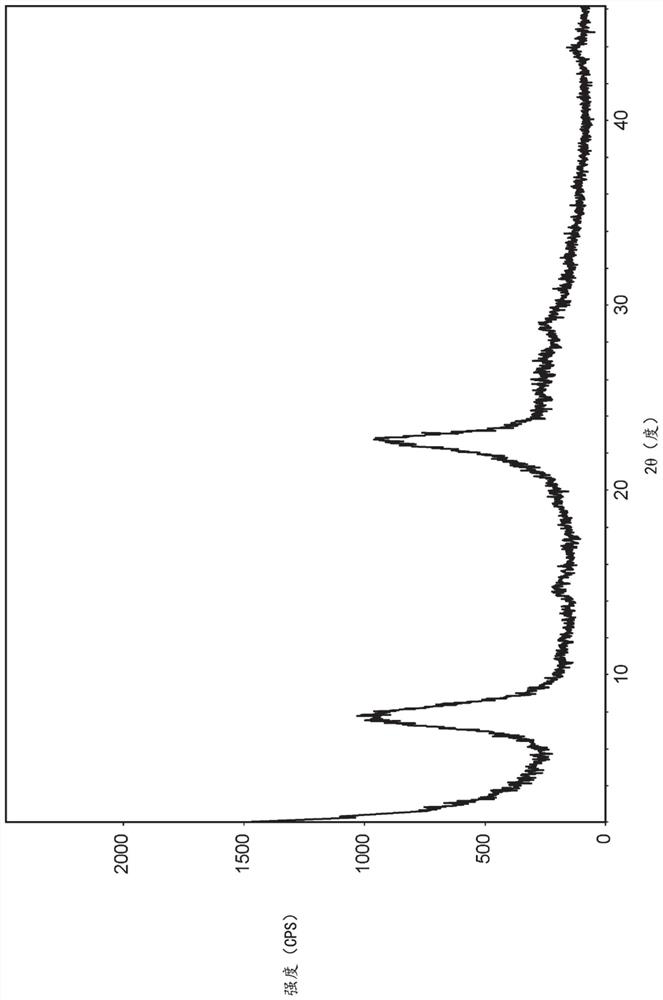

Aluminosilicate zeolite uzm-50

A zeolite and crystal technology, applied in the field of new aluminosilicate zeolites

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0106] Weigh 852.4 g of deionized water into a 2L Teflon bottle. Place the bottle in a 4L beaker, add a stir bar, and begin stirring on a magnetic stir plate. 489.7 g of 97% 1,5 dibromopentane were added. Then 362.7 g of 97% 1-methylpyrrolidine were added. 1.5 L of water (room temperature (RT)) was placed between the bottle and beaker to help spread any exotherm. Let it mix overnight. 1697 g of a yellow solution were recovered.

Embodiment 2

[0108] Weigh 874.8 g of deionized water into a 2L Teflon bottle. Place the bottle in a 4L beaker, add a stir bar, and begin stirring on a magnetic stir plate. 474.1 g of 97% 1,5 dibromopentane (DBP) were added. Then 400.7 g of 99% 1-methylpiperidine were added. 1.5 L of water (RT) was placed between the bottle and beaker to help spread any exotherm. Let it mix overnight. In the morning there was no visible vortex, so not stirring well. Blend the mixture using a Heidolph high-speed mixer throughout the day. This slowly turned into a yellow solution. Mixing was stopped for 52 hours and then resumed for an additional 8 hours. The yellow solution yielded some clear unreacted DBP at the bottom, which was separated. Analysis showed the yellow solution to be 49.5% water.

Embodiment 3

[0110] Under overhead stirring, 1000 g of the product of Example 1 was loaded into a 3 neck round bottom flask. Add 295.4g of 99% Ag 2 O, and cover the flask with aluminum foil. It was mixed for 48 hours at room temperature. A glass filter was used to separate the clear yellow solution. Filter the solution several times over the next week or two. Analysis showed the solution to be 65.5% water.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com