Anti-splashing bullet-proof glass as well as manufacturing method and application thereof

A technology of bulletproof glass and its production method, which is applied in applications, windshields, and other household appliances, and can solve the problems of increasing vehicle weight, increasing fuel consumption, and heavy quality, so as to reduce production and development costs, prevent secondary damage, The effect of small thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

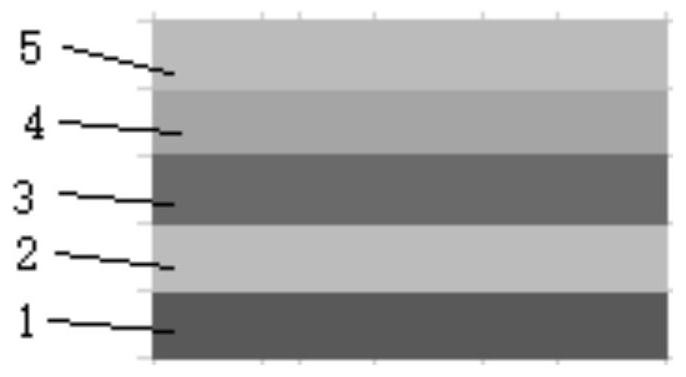

[0059] See Figure 1-3 , the invention provides a method for making splash-proof bullet-proof glass, comprising:

[0060] Cutting the first crystal layer and the second crystal layer respectively so that they both have the target shape, and then cleaning, silk-screen printing, drying and hot-bending the first crystal layer and the second crystal layer respectively;

[0061] Cutting the first plastic layer, the second plastic layer and the third plastic layer respectively so that they all have target shapes;

[0062] Laminating the first crystal layer, the first plastic layer, the second crystal layer, the second plastic layer and the third plastic layer in sequence to form a blank, and the blank is obtained by a lamination process to obtain a glass blank;

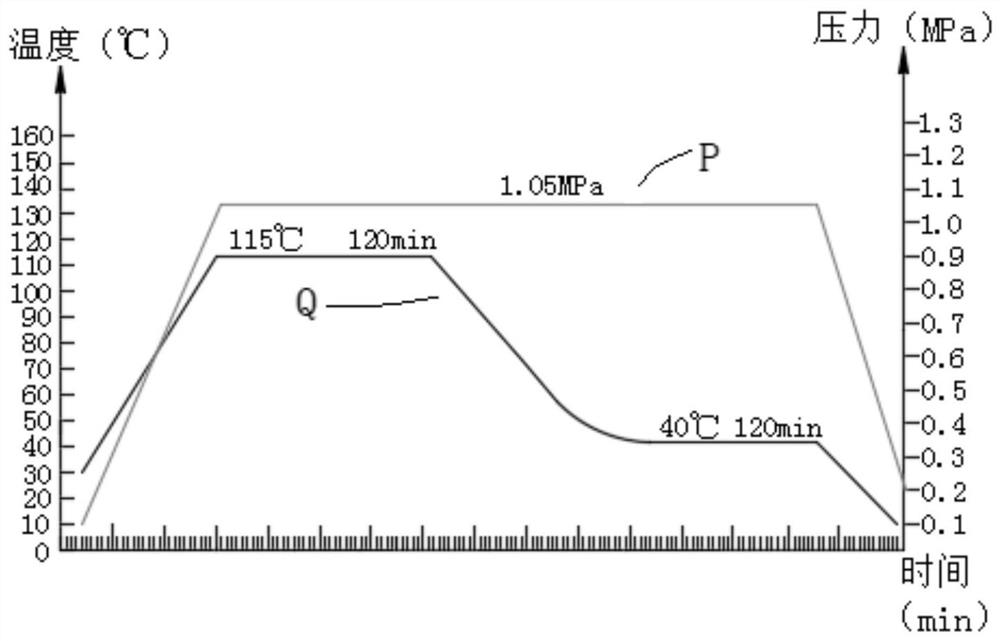

[0063] After the glass blank is vacuum-packaged, it is placed in an autoclave for cold pumping treatment;

[0064] After the glass blank is subjected to high temperature, high pressure, temperature reduction, pressure red...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com