Reinforced composite polyamide film and preparation method thereof

A technology of polyamide film and reinforced composite layer, applied in the field of packaging materials, can solve the problem of insufficient composite strength of polyamide composite film, and achieve the effects of retaining active groups, enhancing composite strength, and reducing processing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

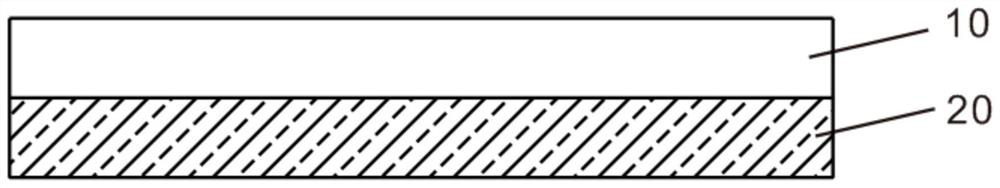

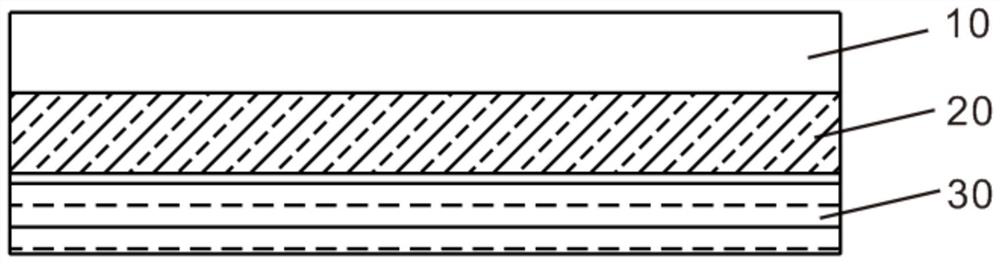

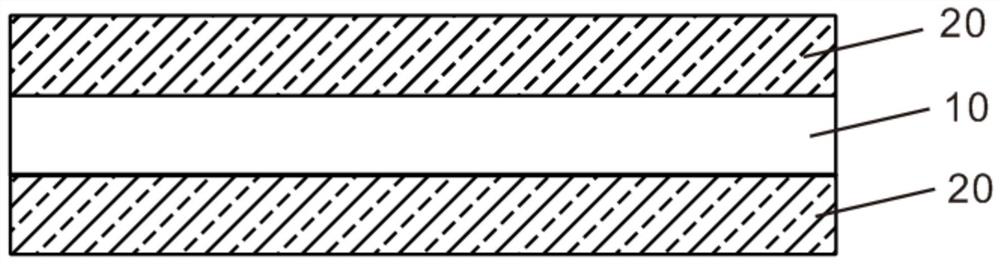

[0038] A reinforced composite polyamide film, comprising a two-layer co-extruded film, the film structure of which is a polyamide layer 10 and a polyamide reinforced composite layer 20 from the outside to the inside;

[0039] The components of the polyamide reinforced composite layer 20 include: 84% of nylon 6 / 66 / 1010 ternary copolymerized nylon, 15% of PAMAM 4.0 generation, 0.5% of silicon dioxide, ethylene bisstearic acid amide in terms of mass percentage 0.5%;

[0040] The components of the polyamide layer 10 include: 100% of polyamide 6 with a viscosity of 2.8 Pa·s in terms of mass percentage.

[0041] And prepare as follows:

[0042] Step 1: After the materials of the polyamide layer 10 and the polyamide reinforced composite layer 20 are melted through their respective extruders, they flow out through a T-shaped die and are cooled on a chill roll to form an unstretched sheet; wherein the chill roll The temperature is 30°C, and the thickness of the unstretched sheet is 1...

Embodiment 2

[0046] A reinforced composite polyamide film, comprising a two-layer co-extruded film, the film structure of which is a polyamide layer 10 and a polyamide reinforced composite layer 20 from the outside to the inside;

[0047] The components of the polyamide reinforced composite layer 20 include: 73% of nylon 6 / 66 / 1010 ternary copolymerized nylon, 25% of PAMAM 4.0 generation, 1% of silicon dioxide, ethylene bis stearic acid amide in terms of mass percentage 1%;

[0048] The components of the polyamide layer 10 include: 100% of polyamide 6 with a viscosity of 2.8 Pa·s in terms of mass percentage.

[0049] Its preparation method is identical with embodiment 1.

Embodiment 3

[0051] A reinforced composite polyamide film, comprising a two-layer co-extruded film, the film structure of which is a polyamide layer 10 and a polyamide reinforced composite layer 20 from the outside to the inside;

[0052] The components of the polyamide reinforced composite layer 20 include: 94.5% of terpolymerized nylon of nylon 6 / 66 / 1010, 5% of PAMAM 4.0 generation, 0.3% of silicon dioxide, ethylene bisstearic acid amide in terms of mass percentage 0.2%;

[0053] The components of the polyamide layer 10 include: 100% of polyamide 6 with a viscosity of 2.8 Pa·s in terms of mass percentage.

[0054] Its preparation method is identical with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com