Method for regulating and controlling dispersity of product of reversible addition-fragmentation chain transfer polymerization method

A technology of fragmentation chain transfer and polymerization, which is applied in the field of reversible addition-fragmentation chain transfer polymerization, can solve the problems of not being diblock copolymers, etc., and achieve the effects of wide control range, easy use, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Embodiment one does not add chain terminator synthetic polymethyl methacrylate (PMMAS)

[0049] Multiple groups of experiments were carried out in parallel, and each group of experiments reacted at different times. The specific method is as follows:

[0050] Moore, [MMA] 0 :[MBr] 0 :[CPDB] 0 :[ACCN] 0 =200:0:1:0.2, sequentially add CPDB (0.0209g), ACCN (0.0046g), MMA (2.0mL) and DMF (2.0mL) in the 10mL ampoule, add a stirring bar, after 3 times of standard After the freeze-pump-thaw aeration cycle, seal the tube under an oxygen-free atmosphere. The sealed ampoule was placed in a magnetic stirrer at 110° C. for a predetermined time and the rotation speed was 600 rpm. After the reaction, take out the sealed tube, open the sealed tube, dissolve it with 2-5 mL of tetrahydrofuran, pour it into 250 mL of methanol, leave it overnight, filter it with suction, and dry it to obtain polymethyl methacrylate (PMMA).

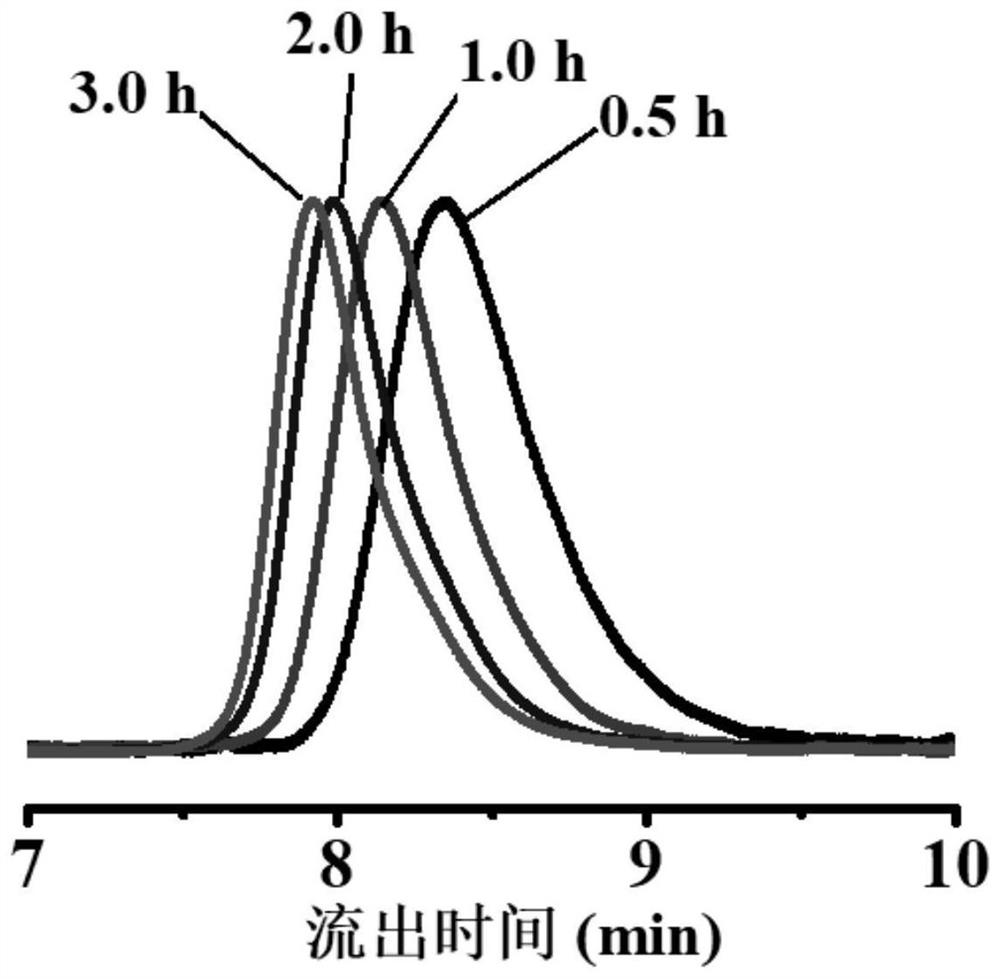

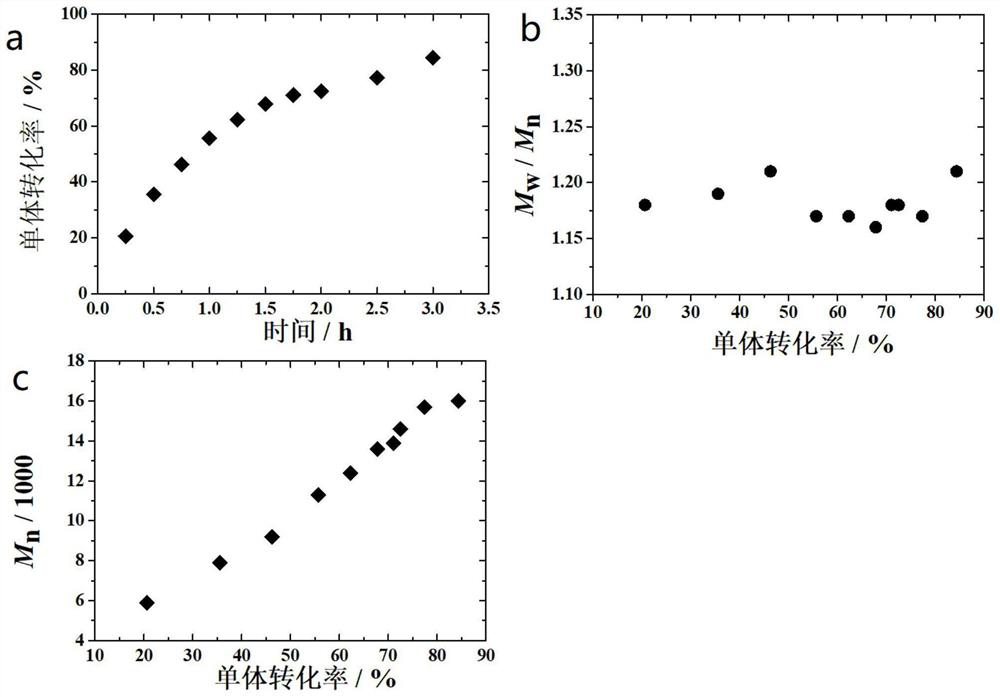

[0051] figure 1 For not adding under the condition of chai...

Embodiment 2

[0054] Example two sample molar ratio monomer: chain terminator: chain transfer agent=200:5:1 synthetic polymethyl methacrylate

[0055] Multiple groups of experiments were carried out in parallel, and each group of experiments reacted at different times. The specific method is as follows:

[0056] Moore, [MMA] 0 :[MBr] 0 :[CPDB] 0 :[ACCN] 0 =200:5:1:0.2, sequentially add MBr (0.0830g), CPDB (0.0209g), ACCN (0.0046g), MMA (2.0mL) and DMF (2.0mL) in a 10mL ampoule, add a stirring bar , after 3 standard freeze-pump-thaw inflation cycles, seal the tube under an oxygen-free atmosphere. The sealed ampoule was placed in a magnetic stirrer at 110° C. for a predetermined time and the rotation speed was 600 rpm. After the reaction is over, take out the sealed tube, open the sealed tube, dissolve it with 2-5 mL of tetrahydrofuran, pour it into 250 mL of methanol, leave it overnight, filter it with suction, and dry it to obtain polymethyl methacrylate.

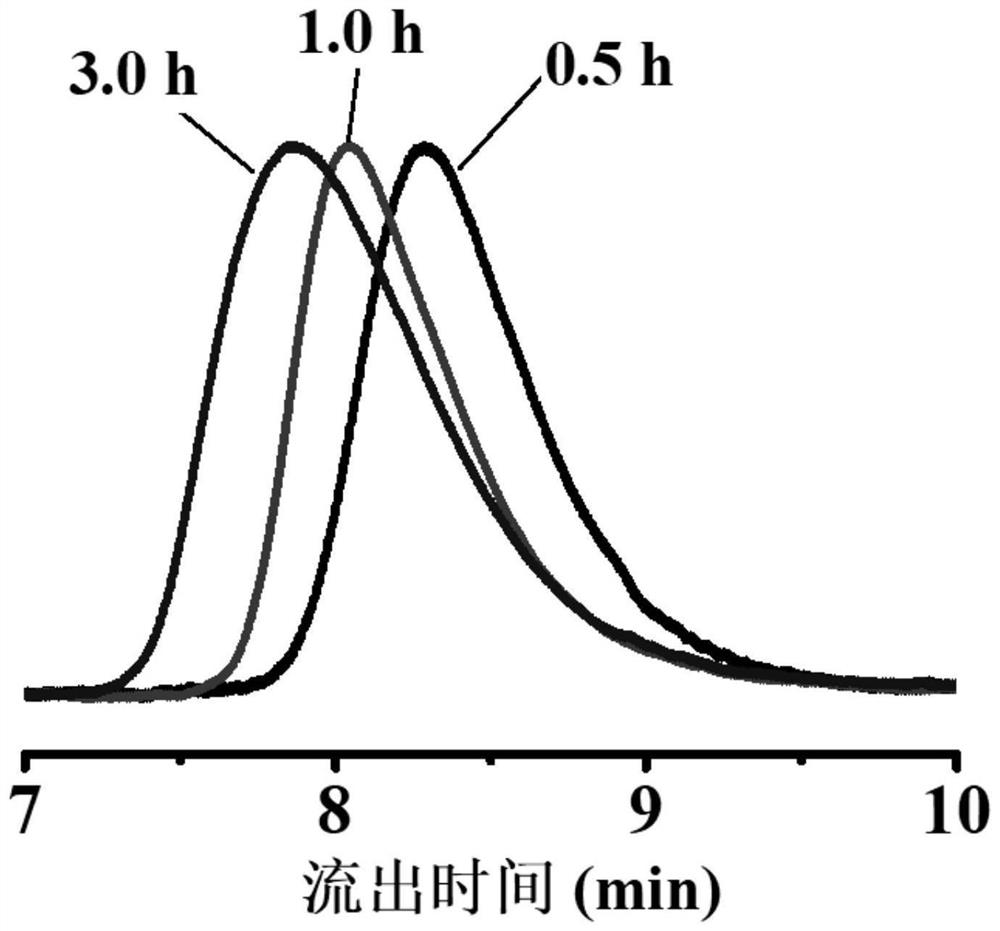

[0057] image 3 For adding...

Embodiment 3

[0060] Embodiment three sample molar ratio monomer: chain terminator: chain transfer agent=200:10:1 synthetic polymethyl methacrylate

[0061] Multiple groups of experiments were carried out in parallel, and each group of experiments reacted at different times. The specific method is as follows:

[0062] Moore, [MMA] 0 :[MBr] 0 :[CPDB] 0 :[ACCN] 0 =200:10:1:0.2, sequentially add MBr (0.1660g), CPDB (0.0209g), ACCN (0.0046g), MMA (2.0mL) and DMF (2.0mL) to a 10mL ampoule, add a stir bar , after 3 standard freeze-pump-thaw inflation cycles, seal the tube under an oxygen-free atmosphere. The sealed ampoule was placed in a magnetic stirrer at 110° C. for a predetermined time and the rotation speed was 600 rpm. After the reaction is over, take out the sealed tube, open the sealed tube, dissolve it with 2-5 mL of tetrahydrofuran, pour it into 250 mL of methanol, leave it overnight, filter it with suction, and dry it to obtain polymethyl methacrylate.

[0063] Figure 5 For ad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com