Method for preparing DMAEMA based amphiphilic block copolymer through single electron transfer living free radical polymerization

A single-electron transfer, amphiphilic block technology, applied in the field of preparing DMAEMA-based amphiphilic block copolymers, can solve the problems of complex process flow, many catalysts, limited development, etc., and achieves high monomer conversion rate and fast polymerization rate. , the preparation method is simple and easy to implement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] 0.1gPDMAEMA~Br(M n GPC =7.04×10 4 , PDI=1.30), 10mLBA (n-butyl acrylate) (0.0701mol), 65mL deionized water were added to a 200mL round bottom flask, copper wire Φ0.26mm, L60cm was added, stirred for 20min with nitrogen, and then added under nitrogen protection 0.6823g TREN (0.0047mol), after five cycles of vacuum pumping and nitrogen filling, place the flask in a constant temperature water bath at 60°C, react for 120min, take out the copper wire, dehydrate and vacuum dry to obtain the target product.

[0027] The monomer conversion rate was 64% as measured by gravimetric method, and the polymer M was measured by GPC. n =13.25×10 4 , PDI=1.85.

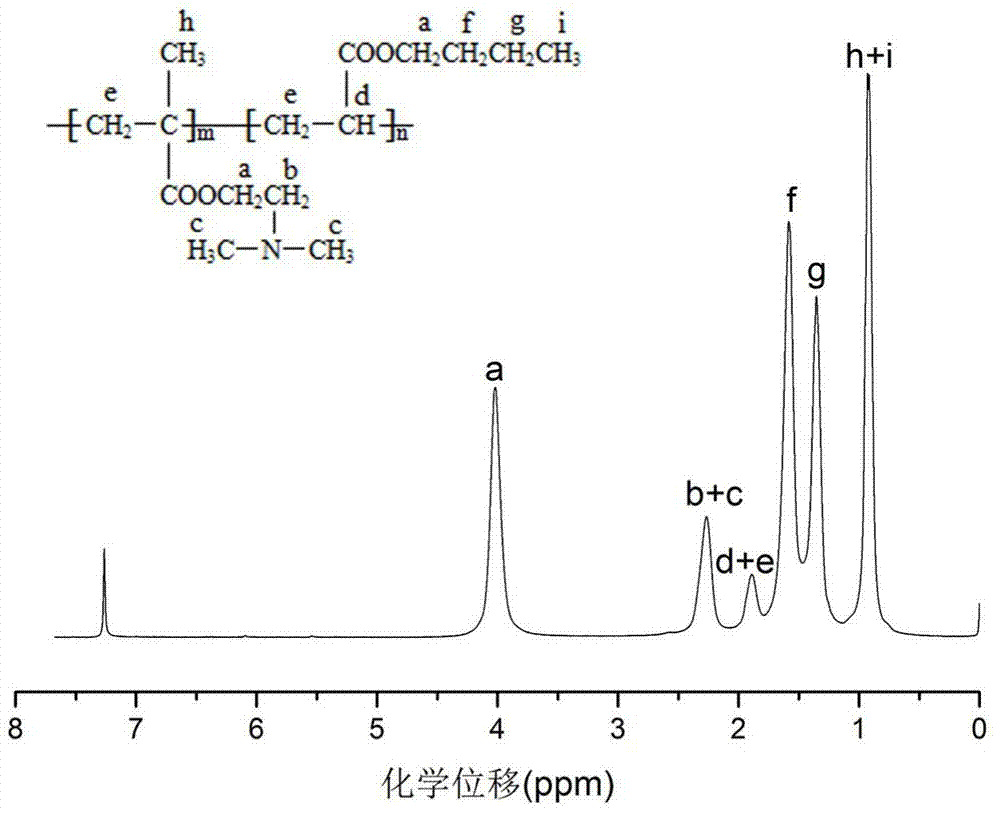

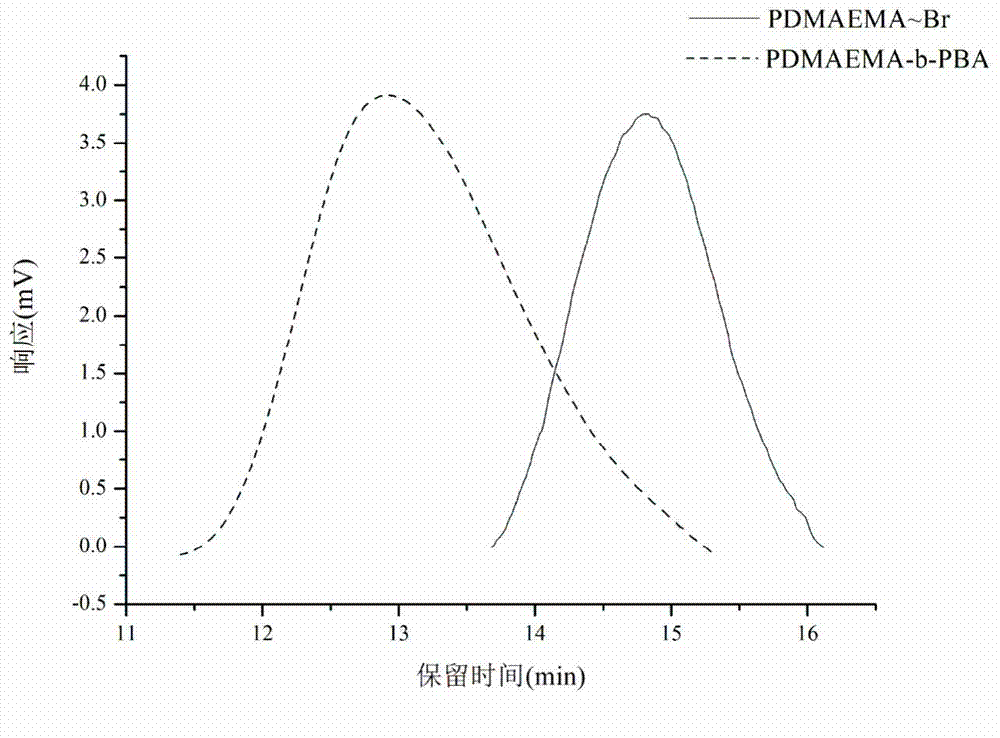

[0028] the polymer 1 H-NMR analysis, such as figure 1 As shown, the signal peaks in the spectrum completely correspond to the hydrogen protons on the two structural units in the block copolymer. The GPC curve of the macromolecular initiator PDMAEMA~Br and the obtained block copolymer is as follows figure 2 As shown, the ...

Embodiment 2

[0030] 0.1gPDMAEMA~Br(M n GPC =7.04×10 4 , PDI=1.30), 10mLBA (0.0701mol), 15mL deionized water were added to a 50mL round-bottomed flask, copper wire Φ0.50mm, L10cm was added, and after stirring for 20min with nitrogen gas, 0.0351g Cyclam (0.00018mol) was added under nitrogen protection , after five cycles of vacuum pumping and nitrogen filling, the flask was placed in a constant temperature water bath at 30°C, and after 120 minutes of reaction, the copper wire was taken out, and the target product was obtained by dehydration and vacuum drying.

[0031] The monomer conversion rate was 84% as measured by gravimetric method, and the polymer M was measured by GPC. n =24.62×10 4 , PDI=1.50.

Embodiment 3

[0033] 0.1gPDMAEMA~Br(M n GPC =7.04×10 4 , PDI=1.30), 10mLBA (0.0701mol), 40mL deionized water were added to a 100mL round-bottomed flask, copper wire Φ0.08mm, L80cm was added, and after stirring for 20min with nitrogen, 1.0183gTMEDA (0.0088mol) was added under nitrogen protection , after five cycles of vacuuming and nitrogen filling, the flask was placed in a constant temperature water bath at 60°C, and after reacting for 90 minutes, the copper wire was taken out, and the target product was obtained by dehydration and vacuum drying.

[0034] The monomer conversion rate was 88% as measured by gravimetric method, and the polymer M was measured by GPC. n =25.37×10 5 , PDI=1.47.

PUM

| Property | Measurement | Unit |

|---|---|---|

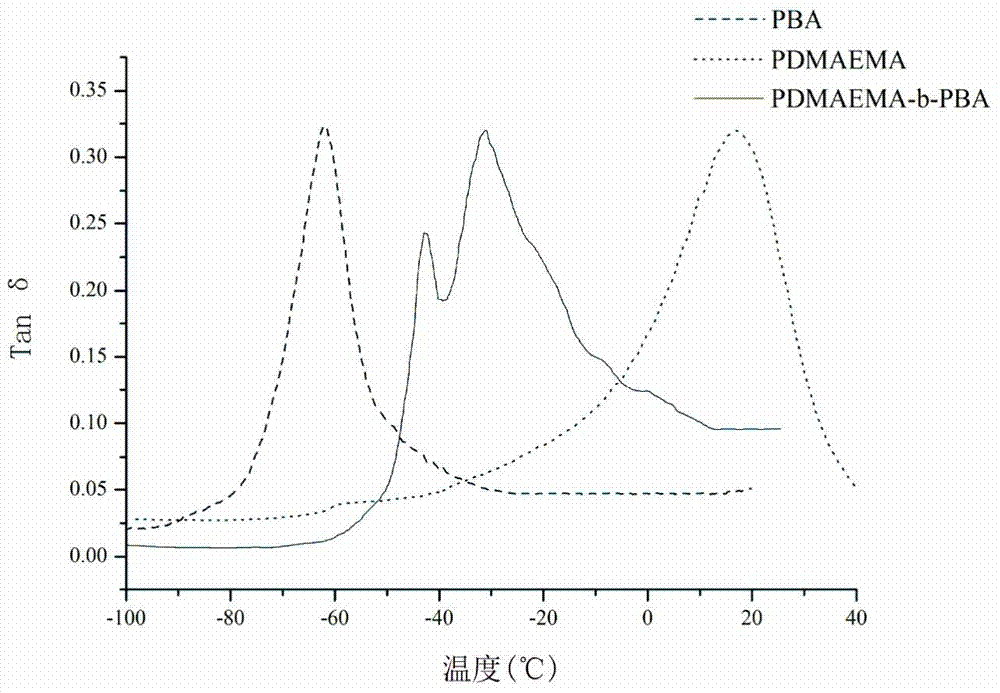

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com