Flue gas waste heat cooling and recycling device

A cooling recovery device and flue gas waste heat technology, applied in the field of flue gas waste heat recovery, can solve the problems of low thermal energy utilization effect, external air pollution, poor flue gas purification and cooling effect, etc. The effect of increasing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

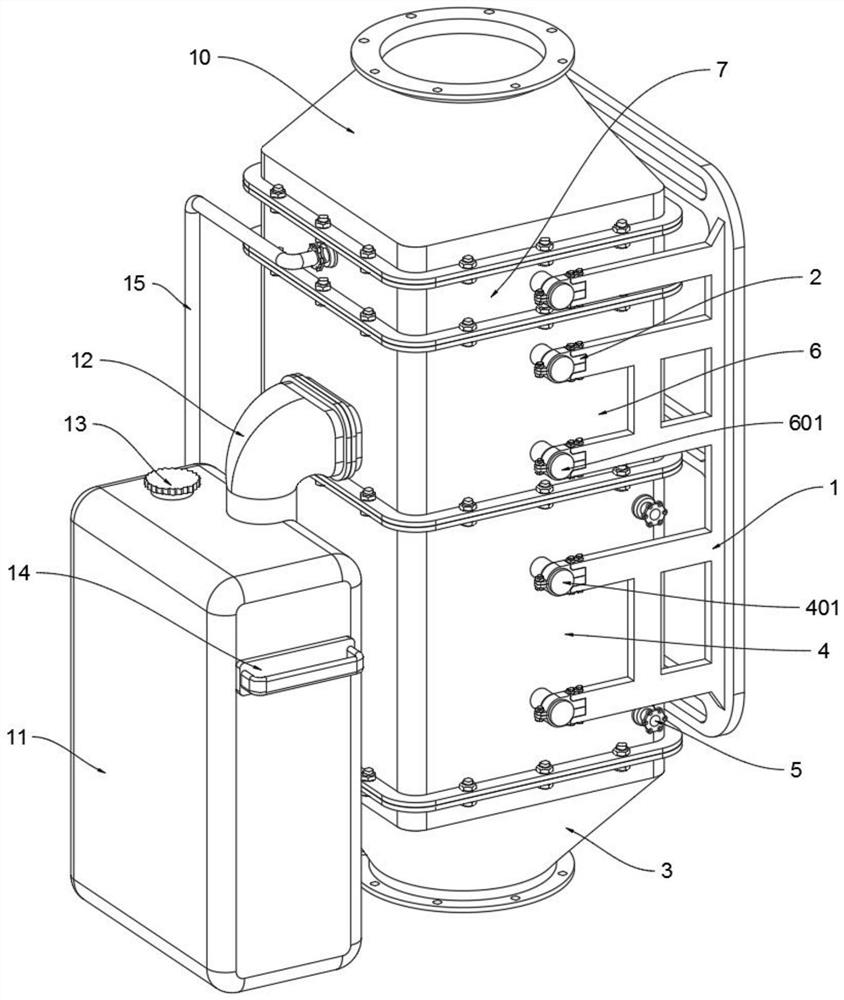

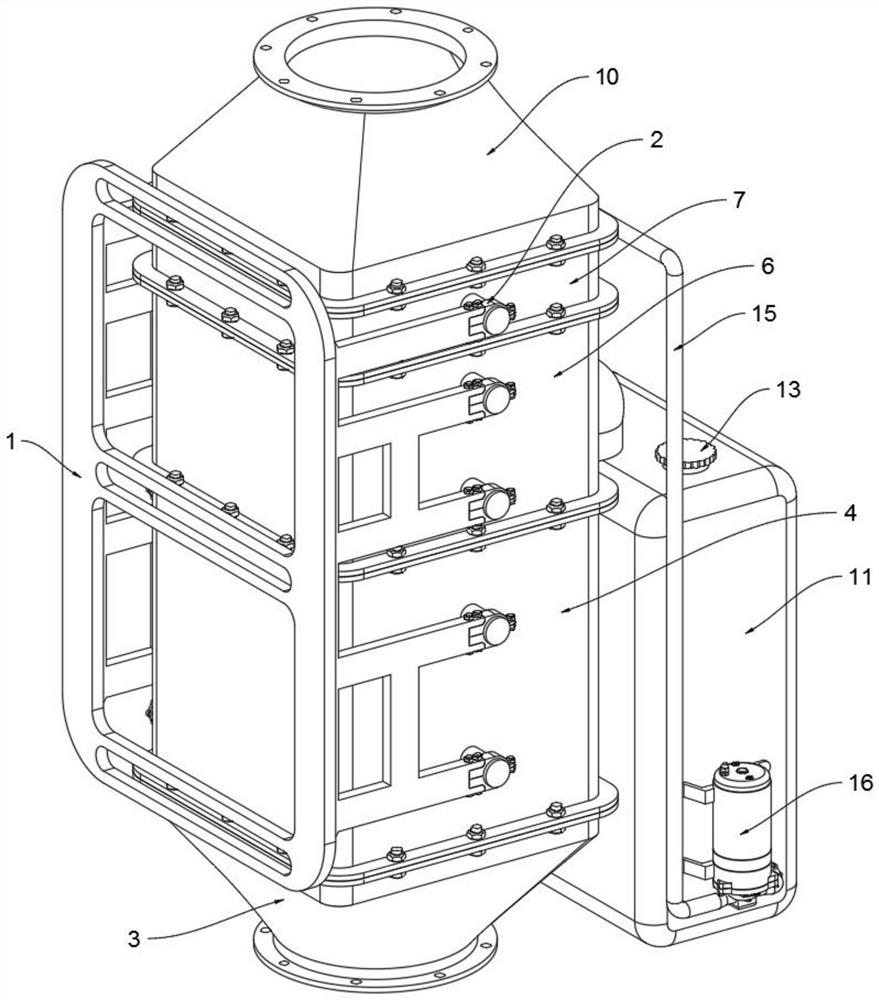

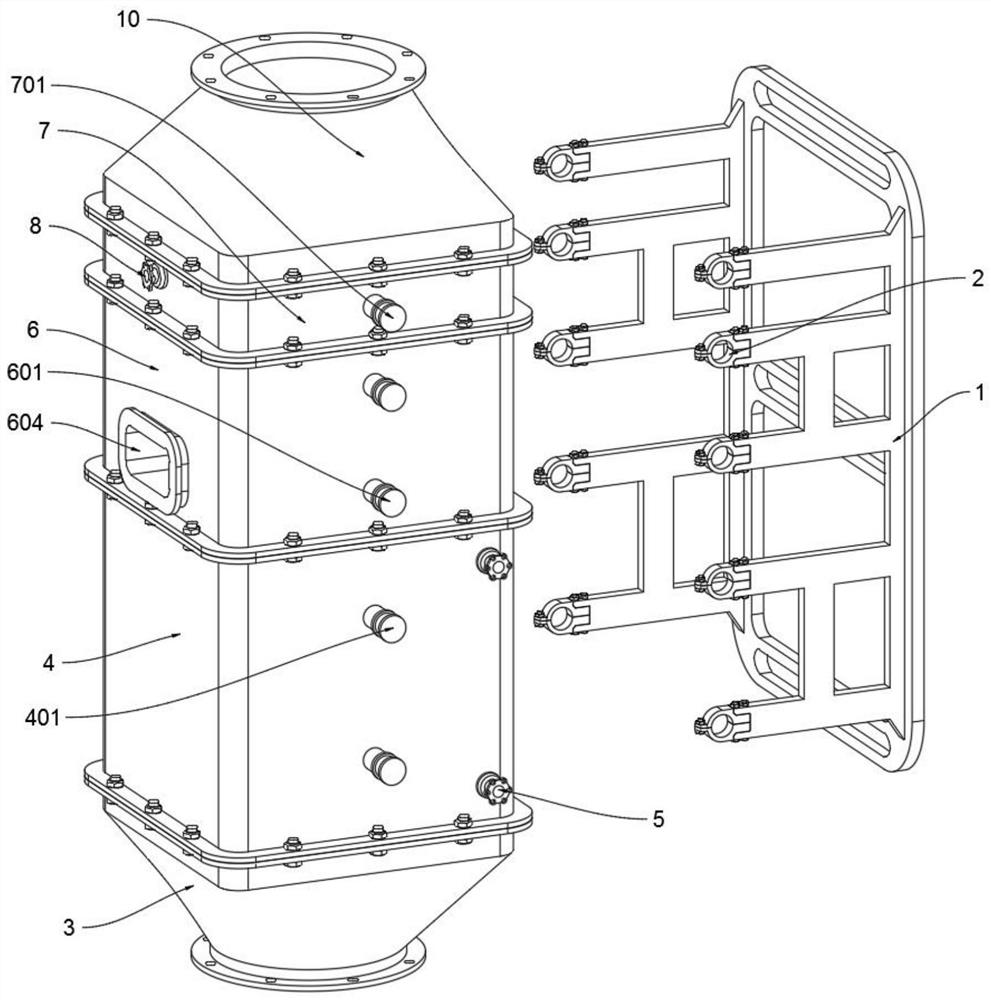

[0035] as attached figure 1 to attach Figure 11 Shown:

[0036]The invention provides a flue gas waste heat cooling recovery device, which includes a movable support frame 1, a smoke inlet pipe body 3, a middle pipe body 6, a water storage tank 11 and a pump body 16; the rear end of the movable support frame 1 is installed on the supporting wall through bolts above, and the connector 2 is symmetrically connected to both sides of the front end of the movable support frame 1; the bottom of the smoke inlet pipe body 3 is connected to the flue gas pipe through bolts, and the top of the smoke inlet pipe body 3 is connected to the bottom of the bottom pipe body 4; The bottom of the tube body 6 is connected to the top of the bottom tube body 4, and the top of the middle tube body 6 is connected to the bottom of the upper tube body 7 through bolts, and the connecting columns B601 on the left and right sides of the middle tube body 6 are respectively connected to the front connector ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com