Wood-based flexible electrode, preparation method and application thereof

A flexible electrode and wood-based technology, which is applied in the manufacture of hybrid capacitor electrodes and hybrid/electric double layer capacitors, etc., can solve the problems of easily damaged substrates, affecting capacitor assembly, and reduced electrode flexibility, so as to achieve excellent electrical conductivity and reduce manufacturing costs. , Improve the effect of specific capacitance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

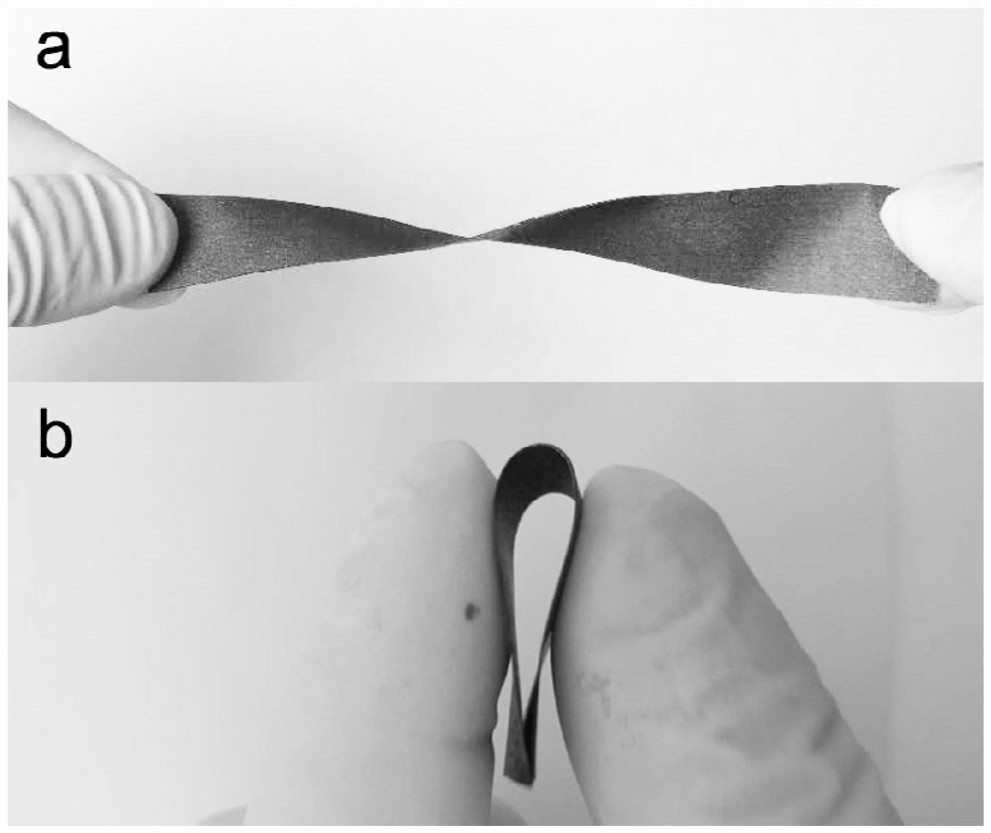

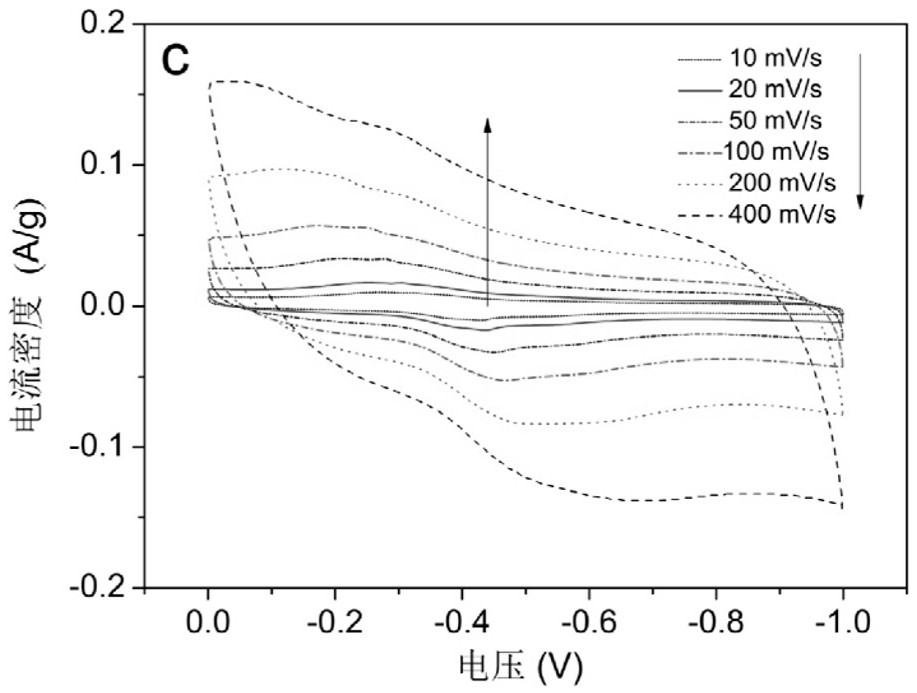

[0037] A wood-based flexible electrode, using sliced beech veneer as the substrate, graphene oxide is loaded in the pores of the substrate, and nano-MnO is loaded on the surface and pores of the substrate 2 , the outermost surface of the substrate is encapsulated with a graphite layer.

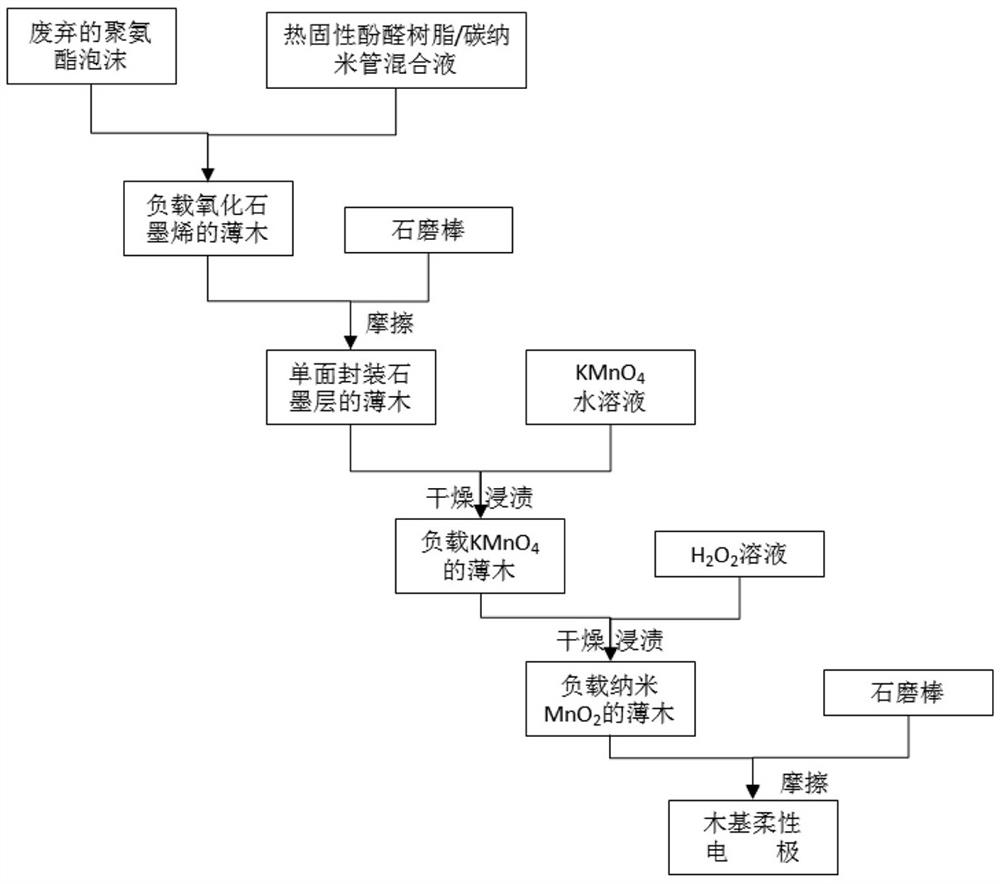

[0038] Such as figure 1 As shown, the preparation method of a kind of wood-based flexible electrode of the present embodiment comprises the following steps:

[0039] 1) Cut the sliced veneer of beech wood with a thickness of 0.2 mm, rinsed with deionized water, and dried into a sheet of 60 mm×60 mm as a filter membrane, put it on the filter paper of the suction funnel, and pour the mass fraction of 2% The graphene oxide aqueous solution is carried out suction filtration as suction filtrate. During this process, the solution was permeated through the veneer and repeated three times, and the graphene oxide was loaded in the pores of the veneer. Then the veneer was flattened, dried at 60 ...

Embodiment 2

[0052] A kind of wood-based flexible electrode, with peeled mandshurica veneer as the substrate, graphene oxide is loaded in the pores of the substrate, and nano-MnO is loaded on the surface and pores of the substrate 2 , the outermost surface of the substrate is encapsulated with a graphite layer.

[0053] A method for preparing a wood-based flexible electrode of the present embodiment comprises the following steps:

[0054] 1) Cut the rotary-cut veneer of Fraxinus mandshurica wood with a thickness of 0.5 mm, rinsed with deionized water, and dried into 60 mm×60 mm sheets, put it on the filter paper of the suction funnel, and pour 3% of the mass fraction Graphene oxide aqueous solution is used as suction filtrate to carry out suction filtration. During this process, the solution was permeated through the veneer and repeated three times, and the graphene oxide was loaded in the pores of the veneer. Then the veneer was flattened, dried at 60 °C to a moisture content of 10%, an...

Embodiment 3

[0063] A wood-based flexible electrode, with sliced red oak veneer as the substrate, graphene oxide loaded in the pores of the substrate, and nano-MnO loaded on the surface and pores of the substrate 2 , the outermost surface of the substrate is encapsulated with a graphite layer.

[0064] A method for preparing a wood-based flexible electrode of the present embodiment comprises the following steps:

[0065] 1) Cut the sliced red oak veneer with a thickness of 0.8 mm, rinsed with deionized water, and dried into 60 mm×60 mm sheets, put them on the filter paper of the suction funnel, and pour 3% oxidation Graphene aqueous solution is carried out suction filtration as suction filtrate. During this process, the solution was permeated through the veneer and repeated three times, so that the graphene oxide was loaded in the pores of the veneer. Then the veneer was flattened, dried at 60 °C to a moisture content of 10%, and the graphene floating powder on the surface of the ven...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com