Synthesis method of ASA

A synthesis method and technology for synthesizing cross-linked acrylate, applied in the field of polymer materials, can solve the problems of poor impact resistance and difficult adjustment of ASA, improve impact resistance and aging resistance, prolong service life, and improve flame retardancy. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

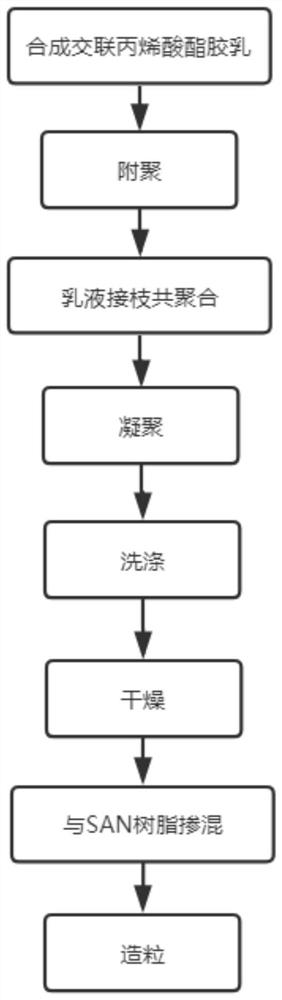

[0034] The synthetic method of ASA, such as figure 1 shown, including the following steps:

[0035] S1: Synthesis of cross-linked acrylate latex: using acrylate with small particle size as seeds, add 0.5 parts of emulsifier, 0.3 parts of cross-linking agent, and 1 part of initiator, heat up to 80°C, and react for 2 hours;

[0036] S2: Agglomeration: Add acrylate monomer under the protection of nitrogen to enlarge the particle size of latex to obtain PBA latex with larger particle size;

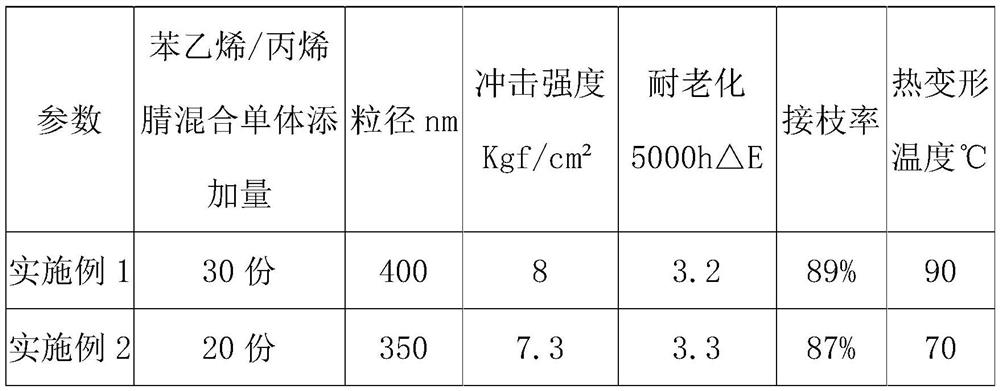

[0037] S3: Emulsion graft copolymerization: Add 30 parts of styrene / acrylonitrile mixed monomer and 0.5 part of initiator to the acrylate seed latex, then add the styrene / acrylonitrile mixture dropwise to the PBA latex at 25 parts / Add dropwise at a speed of h and complete the dropwise addition within 2 hours, add 1.5 parts of antioxidant, 0.2 parts of lubricant and 10 parts of halogen-free flame retardant, heat up to 80°C, stir at 500 rpm for 6 minutes, and react for 2 hours. get the mixtur...

Embodiment 2

[0057] The synthetic method of ASA, such as figure 1 shown, including the following steps:

[0058] S1: Synthesis of cross-linked acrylate latex: using acrylate with small particle size as seeds, add 0.5 parts of emulsifier, 0.3 parts of cross-linking agent, and 1 part of initiator, heat up to 80°C, and react for 2 hours;

[0059] S2: Agglomeration: Add acrylate monomer under the protection of nitrogen to enlarge the particle size of latex to obtain PBA latex with larger particle size;

[0060] S3: Emulsion graft copolymerization: Add 20 parts of styrene / acrylonitrile mixed monomer and 0.5 part of initiator to acrylate seed latex, then add styrene / acrylonitrile mixture dropwise to PBA latex, with 20 parts / Add dropwise at a speed of h and complete the dropwise addition within 2 hours, add 1.2 parts of antioxidant and 0.5 parts of lubricant, heat up to 80°C, stir at 500 rpm for 6 minutes, react for 2 hours, and obtain a mixture;

[0061] S4: Coagulation: put the mixture into ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com