Method for stepwise extraction of nickel, cobalt and manganese from nickel-cobalt-manganese polymetallic oxide ore

A technology of polymetallic oxide ore, nickel cobalt manganese, applied in the field of hydrometallurgy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

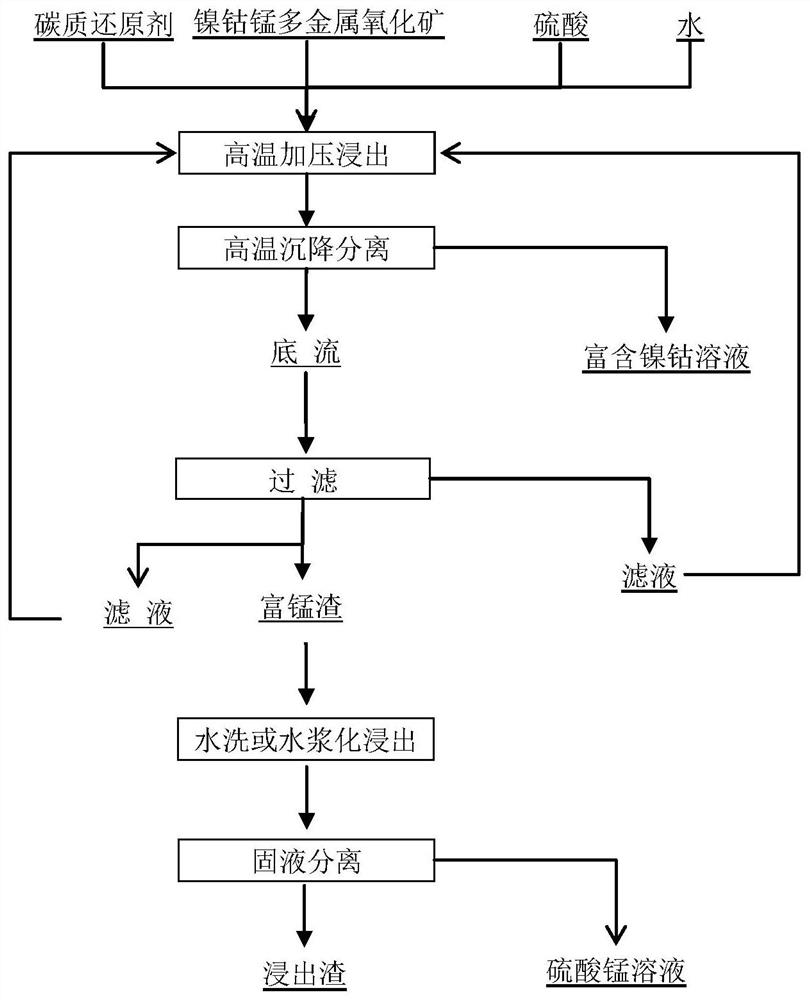

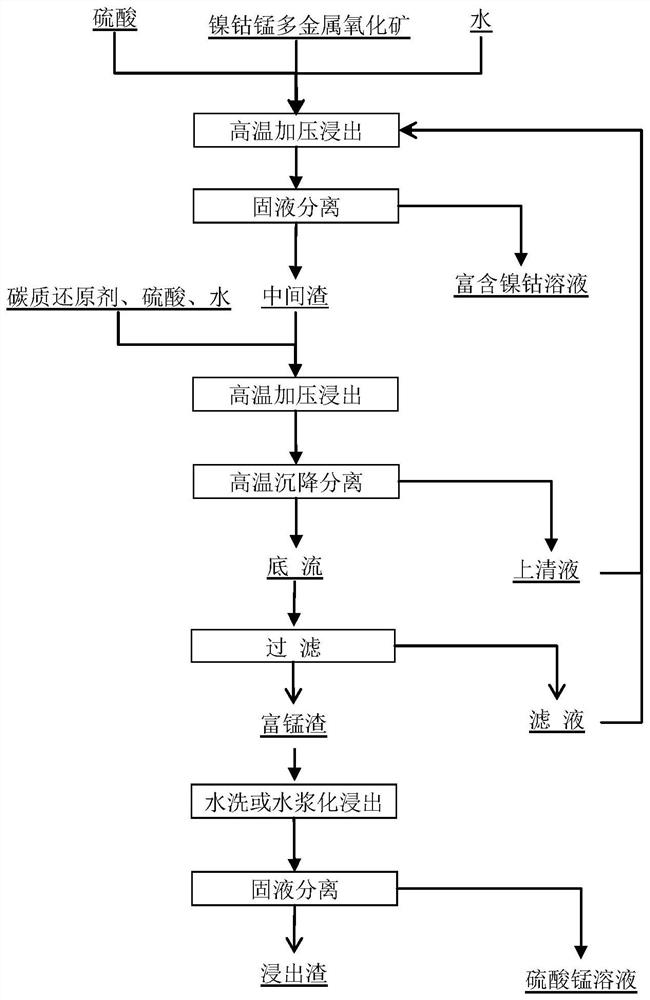

[0051] Mix 100g of nickel-cobalt-manganese polymetallic oxide ore containing 15.0% of Mn, 0.30% of Co and 0.29% of Ni with 1.5 times the theoretical consumption of coke, add sulfuric acid of 1.0 times the theoretical acid consumption of the ore, at a liquid-solid ratio of 4:1 , Pressurized leaching at 150°C for 1 hour, the conversion rate of manganese into manganese sulfate is 99.8%, and the leaching rate of nickel and cobalt is greater than 99.7%. The leached pulp is transferred to a pressure kettle and subjected to high-temperature sedimentation and separation at 150°C 1 Hours, the underflow and nickel-cobalt-rich leachate are obtained, the nickel-cobalt-rich leachate is used for nickel-cobalt recovery, the underflow is filtered to obtain the filtrate and manganese-rich slag, the filtrate can be returned to the leaching ingredients, and the manganese-rich slag is leached with water at 50 ° C for 30 minutes , and then solid-liquid separation to obtain leaching residue and mang...

Embodiment 2

[0053] Mix 100g of nickel-cobalt-manganese polymetallic oxide ore containing 15.0% of Mn, 0.30% of Co and 0.29% of Ni with 1.5 times the theoretical consumption of coke, add sulfuric acid of 1.0 times the theoretical acid consumption of the ore, at a liquid-solid ratio of 4:1 , Pressurized leaching at 250°C for 1 hour, the conversion rate of manganese into manganese sulfate is 99.9%, and the leaching rate of nickel and cobalt is greater than 99.5%. The leached pulp is transferred to a pressure kettle and subjected to high-temperature sedimentation and separation at 250°C 1 Hours, the underflow and nickel-cobalt-rich leachate are obtained, the nickel-cobalt-rich leachate is used for nickel-cobalt recovery, the underflow is filtered to obtain the filtrate and manganese-rich slag, the filtrate can be returned to the leaching ingredients, and the manganese-rich slag is leached with water at 50 ° C for 30 minutes , and then solid-liquid separation to obtain leaching slag and mangane...

Embodiment 3

[0055] Mix 100g of nickel-cobalt-manganese polymetallic oxide ore containing 15.0% of Mn, 0.30% of Co, and 0.29% of Ni with 1.0 times the theoretical consumption of coke, add sulfuric acid of 1.0 times the theoretical acid consumption of the ore, at a liquid-solid ratio of 4:1 , Pressurized leaching at 250°C for 1 hour, the conversion rate of manganese into manganese sulfate is 98.5%, and the leaching rate of nickel and cobalt is greater than 99.2%. The leached pulp is transferred to a settling autoclave and subjected to high-temperature sedimentation separation at 250°C After 1 hour, the underflow and nickel-cobalt-rich leachate are obtained. The nickel-cobalt-rich leachate is used for nickel-cobalt recovery. The underflow is filtered to obtain the filtrate and manganese-rich slag. The filtrate can be returned to the leaching ingredients, and the manganese-rich slag is washed with water at 50°C , to obtain leaching residue and manganese sulfate solution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com