Polyurethane composite reactive printing paste and preparation method thereof

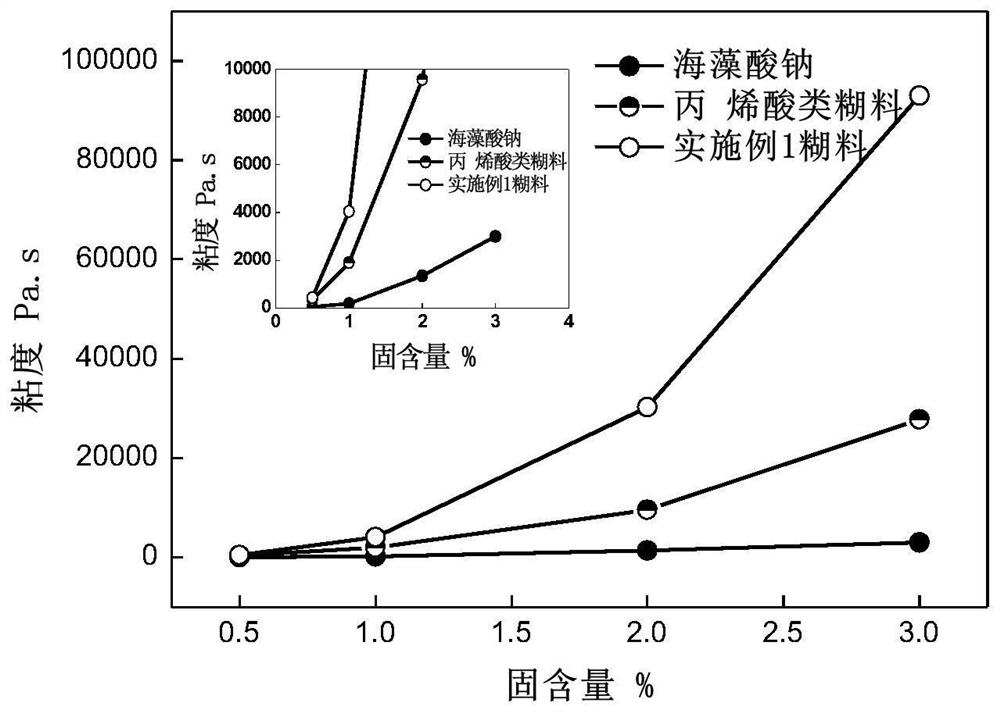

A reactive printing and polyurethane-based technology, which is applied in the fields of textile chemistry and dyeing and finishing engineering, can solve the problems of modified thickeners such as hard hand feeling, poor salt resistance stability, and rising prices, and achieve soft hand feeling, low PVI value, and reduced The effect of printing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

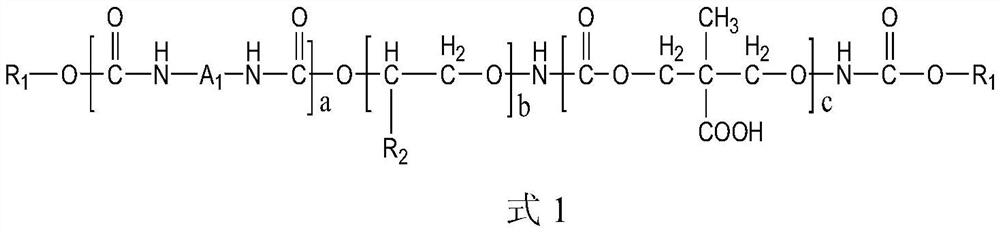

Method used

Image

Examples

Embodiment 1

[0062] The specific raw materials of the polyurethane compound reactive printing paste are: parts by mass, 40 parts of polyurethane thickener; 10 parts of carboxymethyl guar gum; 10 parts of tamarind gum; and 5 parts of sodium sulfate.

[0063] The polyurethane compound active printing paste of the present embodiment is prepared according to the following steps:

[0064] Put 10 parts of guar gum into a double-ribbon mixing mixer and stir, add 40 parts of polyurethane thickener and continue to stir for 20 minutes, add 10 parts of tamarind gum and 5 parts of sodium bicarbonate and continue to stir for 30 minutes to obtain a polyurethane compound paste.

Embodiment 2

[0066] The raw materials for synthesizing polyurethane composite reactive printing paste are specifically: parts by mass, 60 parts of polyurethane thickener; 15 parts of carboxymethyl guar gum; 20 parts of tamarind gum; and 10 parts of sodium sulfate.

[0067] The polyurethane compound active printing paste of the present embodiment is prepared according to the following steps:

[0068] Put 15 parts of guar gum into a double-ribbon mixing mixer and stir, add 60 parts of polyurethane thickener and continue to stir for 20 minutes, add 20 parts of tamarind gum and 10 parts of sodium bicarbonate and continue to stir for 30 minutes to obtain a polyurethane compound paste.

Embodiment 3

[0070] The specific raw materials for synthesizing polyurethane-based composite reactive printing paste are: parts by mass, 50 parts of polyurethane thickener; 27 parts of guar gum; and 8 parts of sodium sulfate.

[0071] The polyurethane compound active printing paste of the present embodiment is prepared according to the following steps:

[0072] Put 27 parts of guar gum into a double-ribbon mixing mixer and stir, add 50 parts of polyurethane thickener and continue to stir for 20 minutes, and 8 parts of sodium bicarbonate continue to stir for 30 minutes to obtain a polyurethane compound paste.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| degree of substitution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com