Method for intelligently controlling SO2 concentration of iron pyrite downhole working face

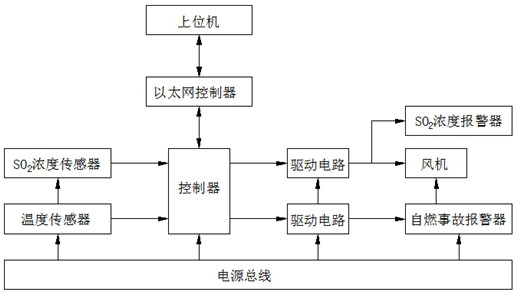

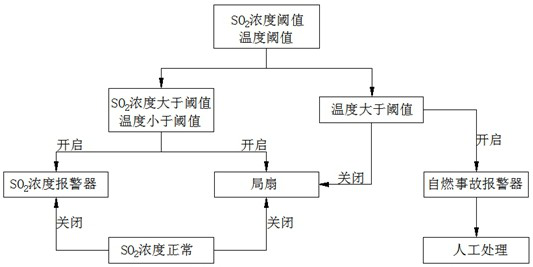

A technology of intelligent control and working face, which is applied in mine/tunnel ventilation, mining equipment, mining equipment, etc. It can solve the problems that concentration monitoring and control cannot be carried out synchronously and in real time, cannot be successfully warned in real time, and spontaneous combustion accidents occur. The monitoring and regulation is not timely, the effect is good, and the effect of accurate monitoring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

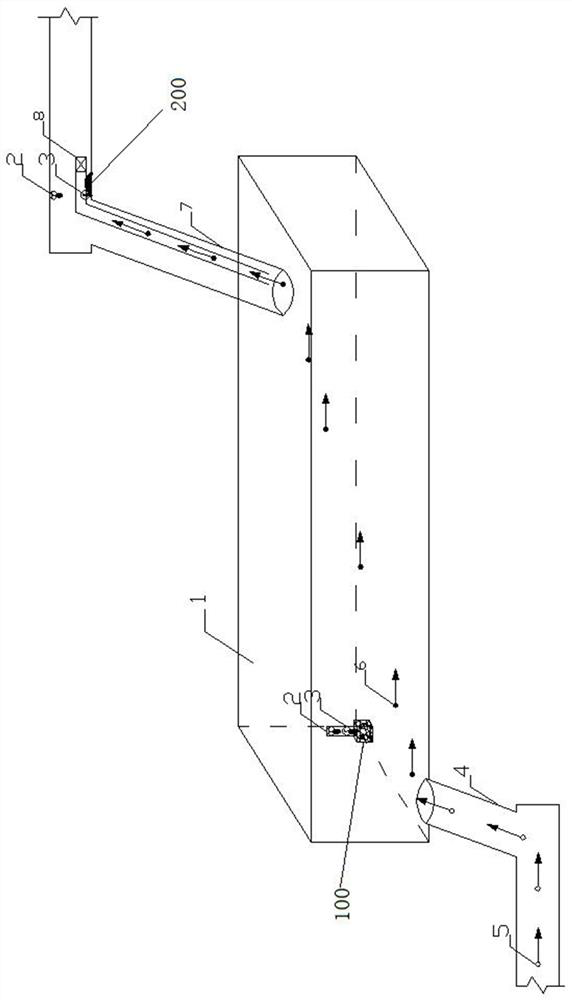

[0035]The implementation steps of this example are as follows: (1) Preparatory work for monitoring of mining face; (2) Selection and arrangement of measuring points in working face; (3) Determination of safety threshold; (4) Installation of monitoring equipment and debugging of monitoring system; (5) The implementation of real-time control of the working face; (6) After the mining of the working face is completed, the monitoring equipment is recovered; the specific operations of the above 6 steps are as follows:

[0036] (1) Preparations for monitoring of mining face

[0037] The main preparatory work includes: mastering the ventilation situation of the working face, the grade of pyrite and the spontaneous combustion of the working face, and the safety situation of the working face.

[0038] (2) Selection and arrangement of working face measuring points

[0039] According to the safety situation of the working face, the measuring point must first ensure the construction safet...

Embodiment 2

[0055] A certain pyrite mine adopts underground mining, and the mining method is upward horizontal layered filling mining method. 2 The poisoning accident and pyrite spontaneous combustion accident caused damage to the mine production. 2 The concentration is intelligently controlled using this technology. Specific steps are as follows:

[0056] (1) Preparations for monitoring of mining face

[0057] The working face to be tested is the stope of the 2# ore body of a pyrite mine. The upward horizontal layered filling mining method is adopted. The stope is arranged along the trend of the ore body, the mining layer height is 3-5m, and the maximum exposure area of the stope is designed. 1000m2, the ore is high-grade pyrite, the average grade is 30%, and the sulfur grade of individual raw ore is as high as 41%; the roof of the stope is stable, the return air tunnel of the stope is stable, and the equipment can be installed safely without support. Ore with a sulfur grade of more...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com