Aqueous hydrophobic silica dispersions

A technology of silica and pyrolytic silica, which is applied in the direction of silica, silica, and liquid-repellent fibers, can solve the problems that are not conducive to the final properties and hinder dispersion, so as to improve the matting performance and increase the Choose and realize the effect of cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0175] Polyurethane-acrylic dispersions were prepared and investigated for dispersion properties such as viscosity, as well as gloss and other properties of cured products.

[0176] The matting agent is provided via the aqueous hydrophobic silica dispersions I and II. The starting materials for the two aqueous hydrophobic silica dispersions were PG 022 dispersion.

[0177] These two aqueous hydrophobic silica dispersions contain MT1100 translucent airgel. In addition to this airgel, Dispersion II also contains 95 micronized precipitated silica.

[0178] Details on the procedure followed in preparing Dispersions I and II are presented in Table 2 below.

[0179] Table 2

[0180]

[0181]

[0182] Dispersions I and II were added to polyurethane-acrylic compositions (NeoPac TM R-9699 water-based urethane / acrylic copolymer) to form compositions I and II:

[0183] table 3

[0184]

[0185] As indicated in Table C (Example 1), additional ingredients were added to...

Embodiment 2

[0197] Starting from the same base dispersion as described in Example 1, namely the CAB-O-SPERSE PG 022 dispersion, the following aqueous hydrophobic silica dispersions I, II and III were prepared. These three kinds of preparations comprise respectively: (I) MT1100 airgel; (II) same A combination of MT1100 airgel and Zeothix 95 precipitated silica; and (III) Combination of MT1100 airgel and S363 micronized wax material. The programs used are shown in Table 7.

[0198] Table 7

[0199]

[0200]

Embodiment 3

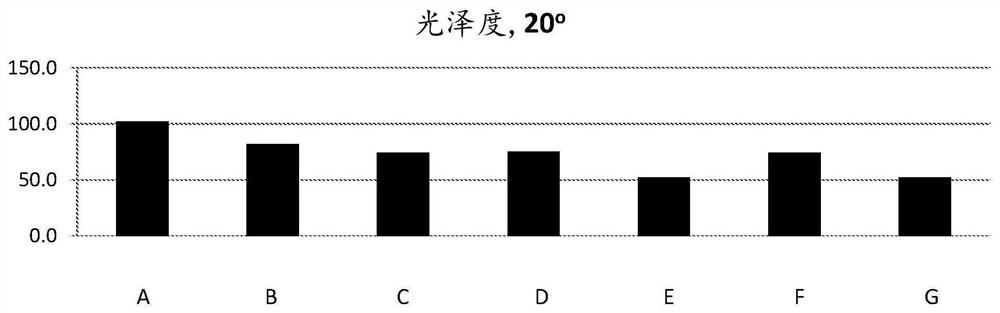

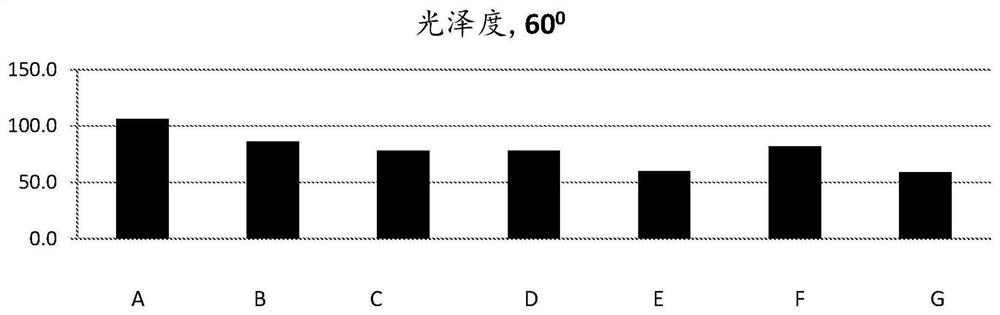

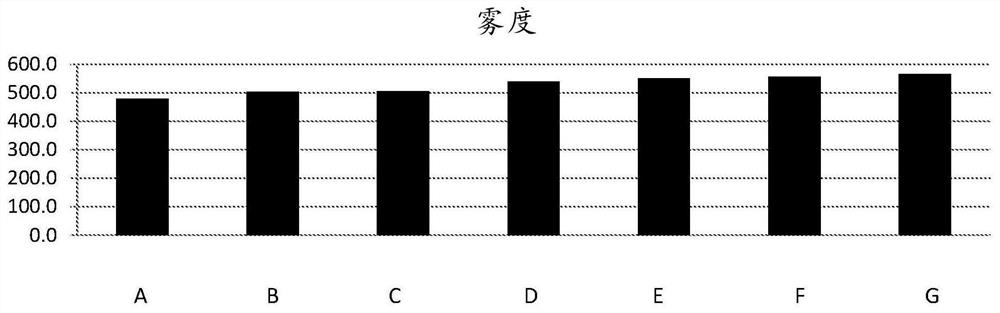

[0203] Dispersions I, II, and III prepared in Example 2 above were mixed with a polyurethane system (NeoRez TM R-960 water-based urethane) were used together to prepare several coating compositions. The labels "low" and "high" refer to the selected relative loadings.

[0204] The procedure followed to prepare the control coating composition and the experimental urethane-based coating composition is detailed in Table 8. Grind fineness is indicated using the Hegman fineness method as described above.

[0205] Table 8

[0206]

[0207]

[0208] a: NeoRez with 34% solid loading TM R-960 water-based urethane.

[0209] The pH and viscosity values observed for the various coating compositions are shown in Table 9 below.

[0210] Table 9

[0211] A B C D E F G control I-Low I-High II-Low II-High III-Low III-High pH 8.10 8.20 8.40 8.50 8.40 8.50 8.60 viscosity 125.00 118.00 129 128 136 132 136

[0212] Test ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com