Preparation process of linseed oil microcapsules, and product thereof

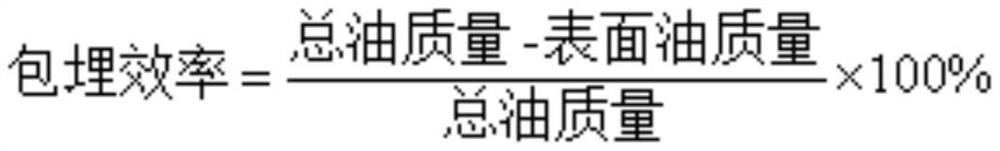

A linseed oil and preparation technology, applied in the direction of microcapsule preparation, microsphere preparation, etc., can solve the problems of large dilution of emulsifier, low embedding rate, easy caking, etc., to avoid oil leakage, embedding High rate, the effect of increasing nutritional value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Weigh 1.71g soybean protein isolate (concentration in water phase is 0.564%, unless otherwise specified below, all are mass percent concentration) and 1.368g maltodextrin (concentration in water phase is 0.451%) and 0.342g Cordyceps sinensis The polysaccharide (concentration in the water phase is 0.113%) was dissolved in 300 mL of water and fully dissolved in a water bath, the temperature of the water bath was 50° C. to obtain the water phase. The mass ratio of soybean protein isolate, maltodextrin, and Cordyceps polysaccharide is 5:4:1, and the mass percentage concentration of the total wall material is 1.128%.

[0047]The water phase was sheared for 2 minutes with high-speed shearing gear 6 (12000r), and 2.56g of linseed oil (core-to-wall ratio was 0.75) was added to the water phase, and the high-speed shearing machine was sheared for 2 minutes at 6 gears (12000r) to form a uniform stable emulsion. Stir magnetically in a water bath at 40°C, add dropwise 25 wt% acetic...

Embodiment 2

[0051] Weigh 2.06g soybean protein isolate (concentration in water phase is 0.680%) and 0.618g maltodextrin (concentration in water phase is 0.204%) and 0.412g Cordyceps polysaccharide (concentration in water phase is 0.136%) to dissolve Fully dissolve in 300mL water in a water bath with a water bath temperature of 50°C to obtain an aqueous phase. The mass ratio of soybean protein isolate, maltodextrin, and Cordyceps polysaccharide is 10:3:2, and the mass percentage concentration of the total wall material is 1.02%.

[0052] Cut the water phase with high-speed shear 6 (12000r) for 2 minutes, add 1.545g linseed oil (core-to-wall ratio is 0.5) to the water phase, and shear 2min with high-speed shear 6 (12000r) to form a uniform stable emulsion. Stir magnetically in a water bath at 40°C, while stirring, add 25% acetic acid solution dropwise to adjust the pH of the system to 4.1, stir at a constant temperature for 10 minutes to obtain a suspension of linseed oil microcapsules, an...

Embodiment 3

[0055] Weigh 2.06g soybean protein isolate (concentration is 0.677% in water phase) and 1.236g maltodextrin (concentration is 0.406% in water phase) and 0.824g Cordyceps polysaccharide (concentration is 0.271% in water phase) dissolving Fully dissolve in 300mL water in a water bath with a water bath temperature of 50°C to obtain an aqueous phase. The mass ratio of soybean protein isolate, maltodextrin, and Cordyceps polysaccharide is 5:3:2, and the mass percentage concentration of the total wall material is 1.354%.

[0056] The water phase was sheared for 2 minutes with high-speed shearing gear 6 (12000r), and 3.09g of linseed oil (core-to-wall ratio was 0.75) was added to the water phase, and the high-speed shearing machine was sheared for 2 minutes at 6 gears (12000r) to form a uniform stable emulsion. Stir magnetically in a water bath at 40°C, while stirring, add 25% acetic acid solution dropwise to adjust the pH of the system to 4.1, stir at a constant temperature for 10 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com