Method for obtaining heterogeneous metal sheet by using composite stamping

A metal thin plate, heterogeneous technology, applied in the direction of metal processing equipment, metal layered products, chemical instruments and methods, etc., can solve the problem that it is difficult to guarantee the bonding strength of the composite interface, the work hardening ability of the material is difficult to guarantee, and the accuracy of the surface treatment of the material is relatively high. Advanced problems, to avoid the doping of impurities and interface oxidation, the flexibility of structure design, the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

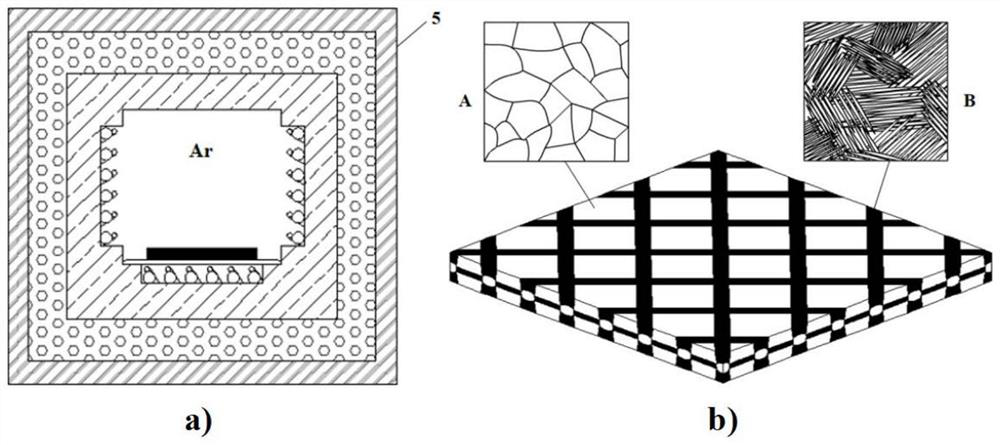

[0033] A novel preparation method of heterogeneous materials. Using the composite stamping process, the martensitic phase transformation is induced by deformation to form a soft and hard structure in the material, and a three-dimensional controllable and designable heterogeneous structure is prepared.

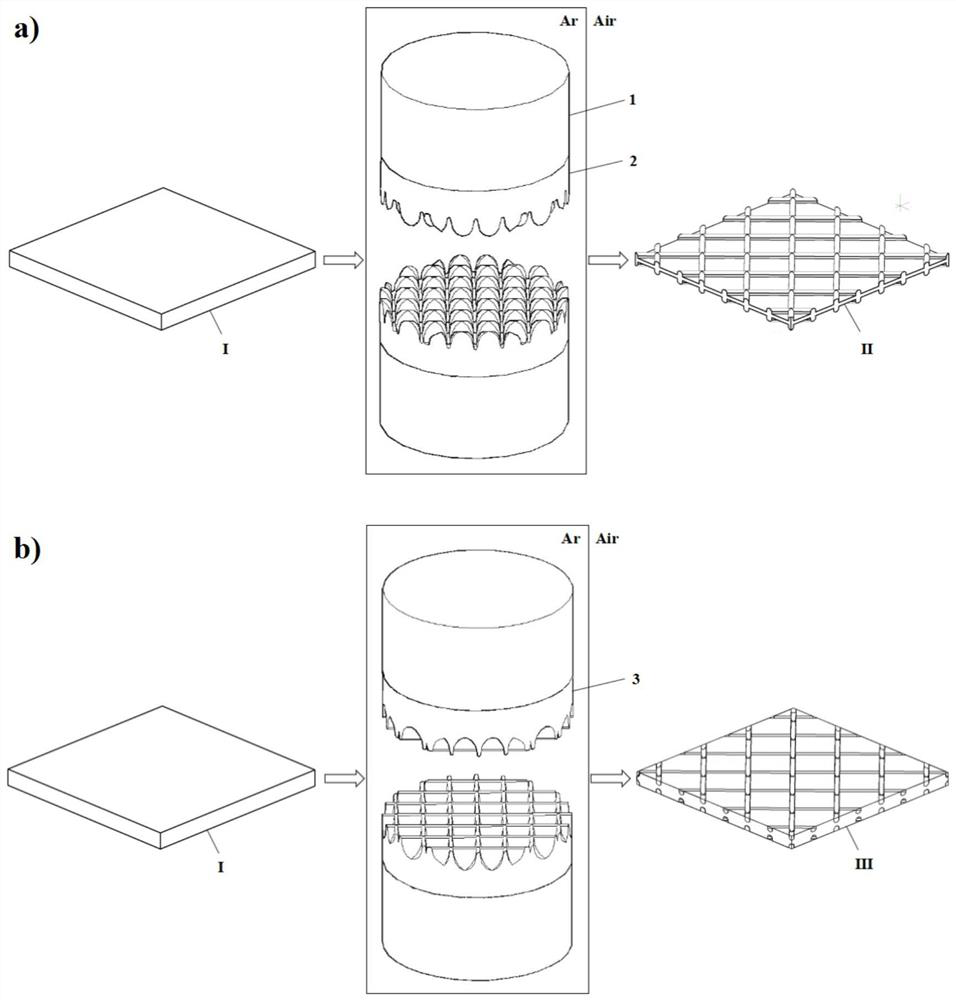

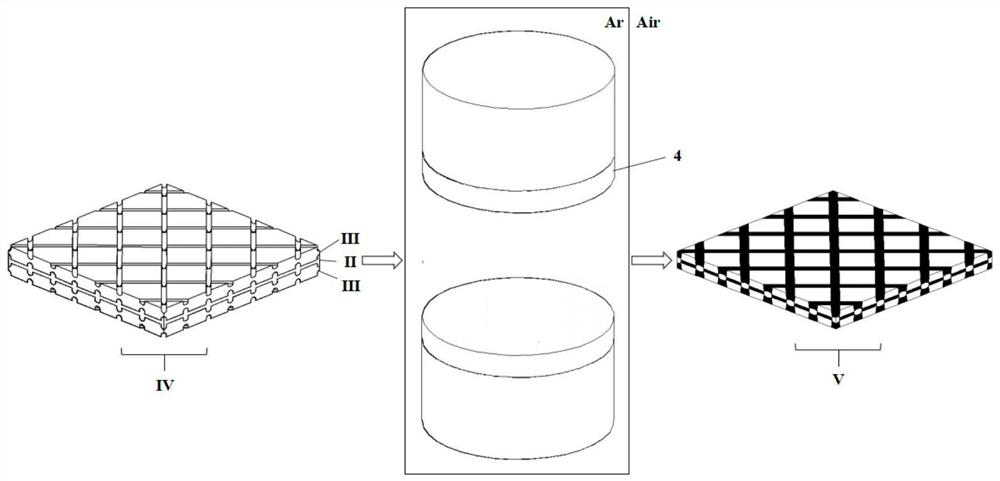

[0034] The composite stamping process specifically includes assembling a detachable mold a on the stamping head of the stamping equipment, stamping sample I to obtain sample II, assembling mold b conjugated with mold a to stamp sample I to obtain sample III, and combining several samples Ⅱ and sample Ⅲ are stacked according to the concave-convex shape of the surface to form a gap-free Ⅲ-Ⅱ…Ⅲ laminated structure, and stamped with a press head equipped with a flat die, and the residual stress is eliminated after heat treatment to form an A / B phase heterogeneous structure. Using high toughness The back stress strengthening and back stress work hardening between phase and high-stren...

Embodiment

[0046] Preparation of Heterogeneous Metal Sheets by Composite Stamping 22Mn5B

[0047] (1) Pretreatment: Select the material 22Mn5B that can deform the martensitic phase, temper it at a high temperature above 1000°C and then cool it in the air to reduce the yield strength to below 100MPa. According to the inscribed square of the indenter disc with a diameter of 800mm, cut 3 plates of 550mm×550mm×1.8mm (length×width×thickness), grind their surfaces with a grinder, finely grind them with sandpaper, and clean and dry them for later use as raw materials Sample I.

[0048] (2) Stamping of complex molds: assemble the upper and lower press heads of the stamping equipment with detachable mold a, and apply G016 lubricating oil on the mold, send sample I between the upper and lower mold a at a rate of 200mm / s, and evacuate to 100Pa and filled with inert gas Ar to atmospheric pressure, heated to 450°C at a rate of 20°C / s and kept warm, stamping and deforming the sample at a stamping rat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com