Filament wound mat production process and device

A technology of production equipment and production process, which is applied in the field of production process and equipment of wire-wound pads, can solve the problems of low resilience, weak hand feeling and use feeling, weak three-dimensional feeling of the surface texture of the foam material, etc., so as to improve the air permeability and The effect of elasticity, improving the three-dimensional texture of the texture and rich hand feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] A kind of production technology of winding pad 10, comprises the steps:

[0042]Step S1: Extrude the filaments through the extrusion mechanism 1, and flow into the constant temperature water tank 6 through the vertical gap 7 between two groups of symmetrically arranged rollers 215 units, and the filaments are mixed and wound to form a mixed winding block;

[0043] Step S2: The wire-wrapped block prepared in step S1 is heated in the constant temperature water tank 6 for initial molding, and then transported out of the water surface by the conveying mechanism 3, and then pressed to a certain thickness by the extrusion roller 4, and then heat-baked. Then the wire wound mat 10 is produced.

[0044] In the step S1, the filaments are silica gel filaments or a mixed filament composed of silica gel filaments and foam filaments, and the foam filaments are silica gel filaments containing a foaming agent; the water temperature in the constant temperature water tank 6 is controlled...

Embodiment 2

[0049] A kind of production technology of winding pad 10, comprises the steps:

[0050] Step S1: Extrude the filaments through the extrusion mechanism 1, and flow into the constant temperature water tank 6 through the vertical gap 7 between two groups of symmetrically arranged rollers 215 units, and the filaments are mixed and wound to form a mixed winding block;

[0051] Step S2: The wire-wrapped block prepared in step S1 is heated in the constant temperature water tank 6 for initial molding, and then transported out of the water surface by the conveying mechanism 3, and then pressed to a certain thickness by the extrusion roller 4, and then heat-baked. Then the wire wound mat 10 is produced.

[0052] In the step S1, the filaments are silica gel filaments; the water temperature in the constant temperature water tank 6 is controlled to 90-100°C.

[0053] In the step S2, the temperature of the heat-baking treatment is 100-160° C., and the heat-baking time is 5-6 minutes.

[0...

Embodiment 3

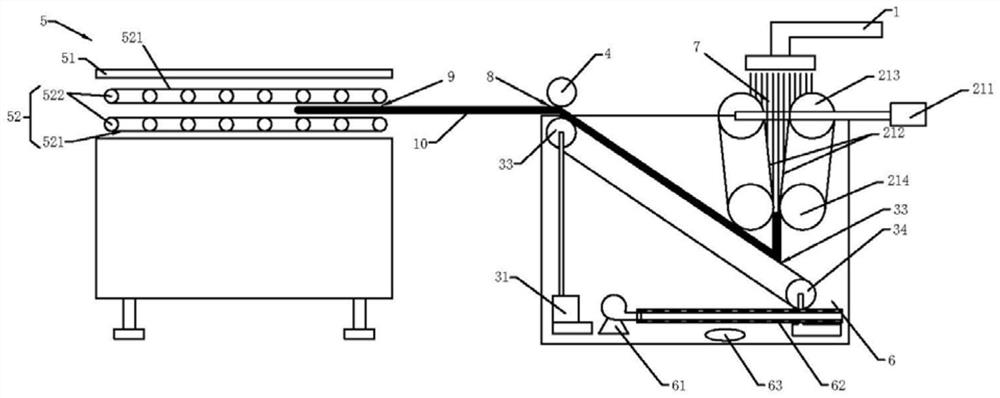

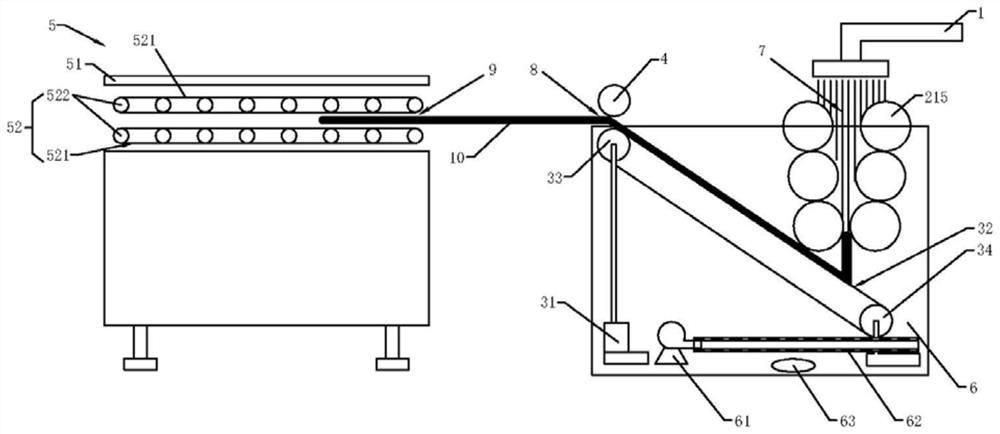

[0056] See figure 1 , a kind of equipment for producing above-mentioned wrapping mat 10, comprises extruding mechanism 1, roller 215 mechanism, conveying mechanism 3, extrusion roller 4 and heat drying mechanism 5 sequentially according to the order of use, and described roller 215 mechanism is arranged symmetrically Two groups of rollers 215 units are formed, the two groups of rollers 215 units are arranged obliquely with respect to the center of symmetry, a vertical gap 7 is formed between the two groups of rollers 215 units, and the width of the vertical gap 7 gradually decreases from top to bottom;

[0057] The transmission mechanism 3 includes a first driving motor 31, a first transmission belt 32, a driving wheel 33 and a driven wheel 34, the first driving motor 31 drives the driving wheel 33 to rotate, and the driving wheel 33 drives the first driving wheel 33 to rotate. A transmission belt 32 rotates, and the first transmission belt 32 is arranged obliquely; the horiz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com